WHAT’S WRONG WITH SAFETY TRAINING . . . AND HOW TO FIX IT

Back by popular demand, this classic analysis by Phil La Duke of the issues and problems encountered with conventional safety training also provides some creative solutions that can enlighten your next session – and get the attention of your workforce.

Posted: December 13, 2011

Back by popular demand, this classic analysis of the issues and problems encountered with conventional safety training also provides some creative solutions that can enlighten your next session – and get the attention of your workforce.

It’s five minutes past the start of your training course and three-quarters of the class still hasn’t arrived. Those participants that showed up on time fidget in their seats and look impatiently at their watches. Somebody runs to a phone and 15 minutes later you finally get started to a class a third of the size it should be. Sound familiar?

Let’s face it, many companies do a poor job of safety training, the participants rarely retain or apply the things they learn, and except for complying with government regulations little is accomplished. Safety training is required to protect workers so why should we have to fight with people to get them to complete the training?

The most common reasons given for resisting safety training include: the training is boring, the material is common sense or doesn’t pertain to me, and we only do it because we are made to go – not because we expect to learn anything useful.

Safety training boring? How could anyone say such heresy? Well, the reality is that most people are turned off by someone reading off PowerPoint slides that literally contain a government regulation. And as for the training not containing information that applies to them, I challenge participants to find a safety topic that doesn’t apply to them.

Years ago I worked seasonal help delivering packages for a postal delivery company. I had a one hour course on lifting and carrying packages. Now given that I would only be working a maximum of six weeks and would not likely be pursuing this work as a career, it would have been easy enough for me to dismiss the class as pointless compliance. Instead, I was surprised to learn useful skills that I remember and use to this day. What was the difference between this course and the hundreds of safety courses I’ve been made to endure over the years?

Simple. This course was effectively designed and expertly delivered and, believe it or not, you can do the same with your safety courses by following some basic rules:

RULE 1: WRITE GOOD OBJECTIVES

Good course objectives are like a checklist of the topics you want to cover, and the more time you spend writing strong objectives the easier it is to write the rest of your course. When writing course objectives ask yourself two questions: “What do I want the participants to be able to ‘do’ when they leave my training course?” and “How will I know that the participates are able to do the things I presented?”

Being the astute reader that you are, you undoubtedly noticed that I said “do” (it helps that I put the word in quotes) and not “know”. The best objectives are measurable and observable behaviors, and while it’s pretty easy to measure what someone can and cannot do, it’s darn near impossible to tell what someone knows, unless there’s an accompanying observable behavior.

In broad strokes, when we talk about imparting knowledge we are talking about “education” and when we talk about teaching a skill we are talking about “training”. Let’s put it this way, you may be in favor of your fifth grader getting sex education, but probably wouldn’t be crazy about him or her getting sex training. Every good instructional objective will have three elements:

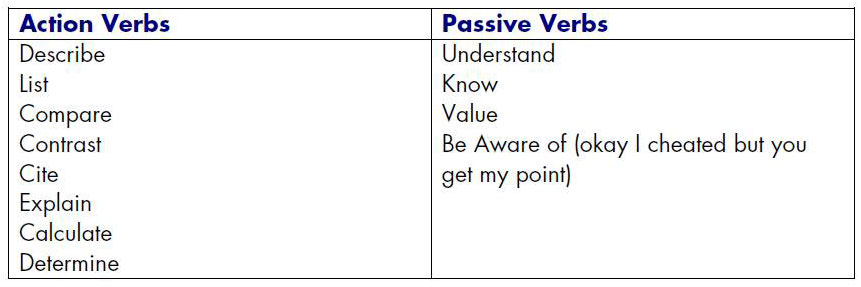

1. Identification of the skill expressed using action verbs

2. Criteria for success

3. Measurement parameters

Identification of a skill using action verbs may seem fairly obvious to you, but when you sit down with pen and paper and try to write an objective that clearly identifies the skills you want to impart, it can get difficult, even frustrating.

Action verbs denote a person doing something, which is important when you are trying to provide skills training because when you train someone, you really want them to DO something. So when you write an objective it’s crucial that you use an action verb to describe what you want the participants to be able to do. The table below is far from an exhaustive list, but it’s a good place to start:

Establishing a criteria for success also SEEMS easy, but can be even more difficult than describing the skill, but once you’ve determined what actions the participants will be able to perform you need to identify how good is “good enough”. The perfectionists among you will demand 100 percent and that’s laudable, but it also sets up an unrealistic expectation and the likelihood that you will end up retraining a boat load of participants who will never pass with 100 percent accuracy.