Stamping Out a New Generation of Automobile Parts

The question Ford and General Motors asked was how to produce hoods and doors with improved productivity, design flexibility and reduced costs. The answer from Schuler, Bosch Rexroth and Morrell was a compact crossbar transfer press that does all that and more.

Posted: January 27, 2012

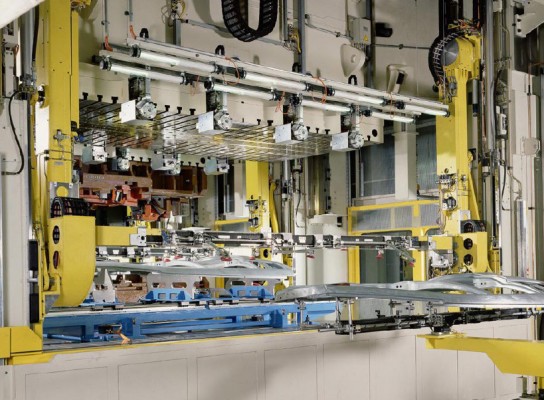

The press measures 30 ft above floor and 18 ft under floor, with a total length of 197 ft and a total weight of 3,000 tons. “There are no manual operations on the crossbar transfer press,” explained Kreth. “The crossbar transfers each part using vacuum cups in an across-flow direction with no drop and much less vibration. Die changes are completed in two steps, with one die set in and one die set out in 10 minutes to 15 minutes. The seven programmable axes drastically improve flexibility and expand design freedom.”

At the heart of the crossbar transfer press lays a modular transfer system that guarantees the safe transport of parts between the various forming stations. In contrast to conventional mechanical or electrical transfer systems using a central drive system, this modular transfer system consists of autonomous units equipped with their own electronic drives that allow manufacturers to optimize the transfer motion for two forming stations at one time, according to the particular part shape. Independent drives also mean press speed and transfer motion can be adjusted separately, so even difficult shapes with inclined forming positions in the die can be produced in continuous operation.

In addition to independent control, the machine is also considerably more flexible than a conventional transfer press and can produce a wider range of parts. The press is capable of increasing output by 15 percent to 20 percent across the entire part spectrum. This is further complemented by its transfer motion possibilities and flexible part orientation with seven axes, permitting more simplified die designs.

Despite its advances in part output and design flexibility, the compact crossbar transfer press actually incurs lower investment costs because numerous mechanical drive components have been replaced by less expensive electronic systems, and a modular design simplifies maintenance and spare parts inventory. The number of part-specific transfer accessories has also been drastically reduced.

That’s not all. Shaped templates for the intermediate stations have been eliminated while the number of toolings used in a conventional line was reduced by nearly half. In addition, parts are no longer deposited between forming stations, so the press requires approximately 15 percent less space than a conventional crossbar transfer press. Mike Tonyan, a regional manager for Bosch Rexroth industrial hydraulics and Jeff Grube, a Bosch Rexroth industrial hydraulics project manager, noted that the installation of these presses was a six- to ten-month process.

“The goal of these presses is to provide greater capability and performance, increase per hour throughput and decrease per-hour rejects,” said Grube, who explained that his group was responsible for the axial piston pumps and internal gear pumps, relief valves, proportional reducing valves, directional valves and logic valves, while his German parent supplied the high-response manifold assemblies and control systems to coordinate the cushion cylinder stroke and function. Morrell and Bosch Rexroth split the manufacturing work of the hydraulics/control portions to complete the total of five presses.