Stamping Out a New Generation of Automobile Parts

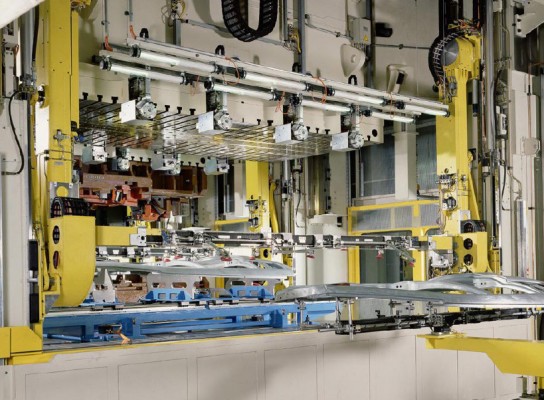

The question Ford and General Motors asked was how to produce hoods and doors with improved productivity, design flexibility and reduced costs. The answer from Schuler, Bosch Rexroth and Morrell was a compact crossbar transfer press that does all that and more.

Posted: January 27, 2012

The gear pump “idler” gear may be driven directly by the “drive” gear, depending on the number of teeth. The teeth on the gear pumps can be spur (straight), helical (slanted), herringbone, etc., each having different effects on the efficiency, strength and smoothness of operation. Two pairs of valves can be added to create a reversing gear pump that pumps in the same direction regardless of which direction the gears rotate. Fixed-displacement gear pumps are the most common hydraulic component because they are simple in design, with few moving parts, but are capable of meeting the rigors of industrial use. In this particular case, the gear pumps being used produce very low noise to help meet the strict automotive noise level requirements.

Proportional pressure-relief valves are used to limit the pressure in a hydraulic circuit and allow this limit to be adjusted by electronic control. While relieving the pressure, excess flow is returned to the tank. Proportional pressure-reducing valves regulate downstream pressure in a branch circuit and allow this set limit to be adjusted by electronic control. These reducing valves are optimized to reduce the effect of pressure changes due to varying flow rates. Their transient response prevents excess pressure, or overshoot, and under pressure during changes in desired pressure conditions. This means very low pressures can be controlled accurately and the valves continue to operate even if the flow becomes static.

High-response proportional directional valves are used in the closed-loop systems to control position, velocity, pressure or force. They approach a servo-value performance without the associated higher costs for the same flow range. Directional control valves are typically the most universally applied products available for controlling the start, stop and direction of fluid flow in a circuit. Directional valve technology in the form of sliding spool, poppet type, screw-in cartridge valves and DIN cavity installations offer precise tolerances, exact machining methods and highly engineered spool profiles. This provides flexibility and variability to individual circuit or system solutions.

The cushioning system was designed by Schuler and supported by Bosch Rexroth using proven standard Rexroth components. Ideal cushioning is used, which means there is no end-of-stroke bounce. The direction of piston travel is the same throughout the entire cushioning sequence and its velocity is exactly zero when it reaches the end of its travel.

At the end of the day, this technology has enabled each crossbar transfer press to be more productive and flexible than a conventional line, stamping out 15 percent to 20 percent more quality auto body parts. The modular transfer system guarantees the safe transport of parts between forming stations for a lower investment cost, and it uses 15 percent less space. And the maintenance and spare parts inventory has been simplified.

Schuler Incorporated, 7145 Commerce Boulevard, Canton, MI 48187, 734-207-7200, Fax: 734-207-7222, www.schulerinc.com.

Bosch Rexroth Corporation, 5150 Prairie Stone Parkway, Hoffman Estates, IL 60192-3707, 847-645-3600, info@boschrexroth-us.com, www.boschrexroth-us.com.

Morrrell, Inc., 333 Bald Mountain Road, Auburn Hills, MI 48326, 248-373-1600, Fax: 248-373-0612, info@morrellinc.com, www.morrellinc.com.