Bandsaw Blunders: How They Cut Blade Life

Ron Saxon and David Rosing of Simonds International reveal the top five sawing mistakes . . . and how to prevent them.

Posted: February 17, 2012

(4) DON’T BE TENSE

Hypertension isn’t good for anyone or anything, especially your bandsaw. Blades that are either too tense or too loose can cause problems, so make sure your blade is in a nice state of equilibrium. Most bandsaws work best with blade tension set to a minimum of 25,000 lb psi or a maximum of 32,000 lb psi. Anything less than 25,000 lb psi leads to poor beam strength, band fatigue or crooked cuts; more than 32,000 lb psi and you could break the band, crack the gullets or wear out machine bearings.

SOLUTION: Use a gauge to measure and properly set blade tension. If you don’t have a gauge or don’t know how to use it, give us a call and we’ll give you a free check and help you correctly set blade tension.

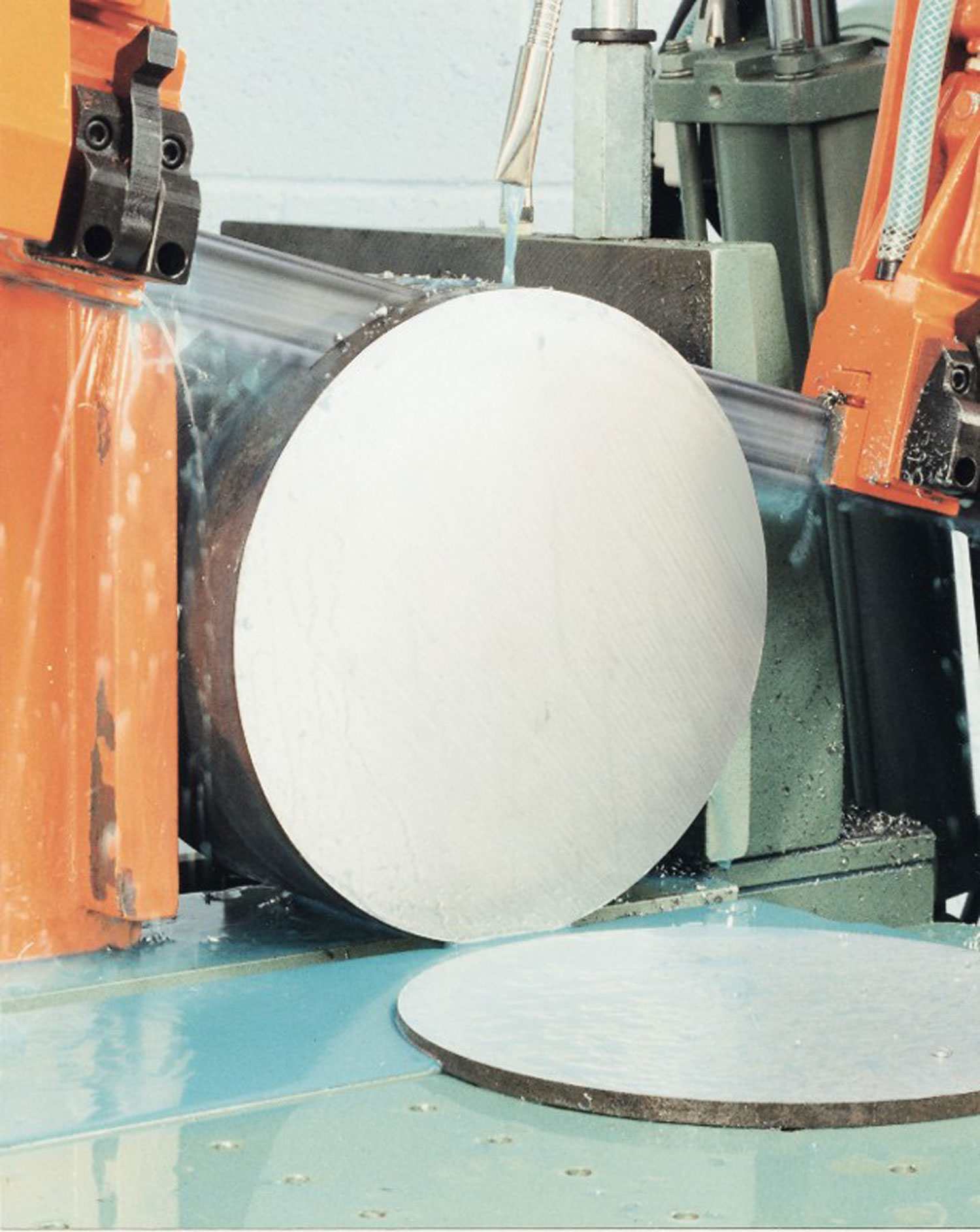

(5) APPLY THE BREAKS

Just like a new car or pair of shoes, you need to break in your blade. This will “hone” the teeth and extend blade life. Think of brand new blade teeth as freshly sharpened pencil tips. If you press down too hard on a pencil, you’ll break off its tip. A bandsaw tooth reacts the same way. Excessive feed pressure breaks pointed edges of bandsaw teeth.

SOLUTION: The best way to break in new bimetal blades is to reduce the normal feed rate by half during the break-in period. Band speed isn’t what breaks teeth during blade break-in; pressure from excessive feed rate is the most damaging dynamic. You will greatly improve the life of your blade if you take the time to break it in properly.

A Handy Formula for Breaking-In Bi-Metal Blades

- Break-in rate: Fifty percent of recommended blade feed rate

- Break-in formula: Multiply the recommended blade speed by 25 percent and cut that number of square inches.

Examples

Recommended blade feed rate: 200 fpm

- Break in for: 50 sq in

Recommended blade feed rate: 100 fpm

- Break-in for: 25 sq in

Once you approach the end of the break-in period, you can gradually bring your bandsaw feed rate back to normal. It is true that some blades are broken-in at the factory, but we recommend that you still use our break-in formula to make sure your blade is honed to perfection.

As the economy begins to improve, factories are under increasing pressure to perform. But even as you work hard to keep pace, there are no shortcuts to optimal performance – yours or the blade’s. Take time to get the information you need to do the job right, and cut out those mistakes.

Ron Saxon is a certified bandsaw operator and David Rosing is the technical manager of band saw products at Simonds International, 135 Intervale Road, PO Box 500, Fitchburg, MA 01420, 978-424-0100, Fax: 978-424-2212, www.neveryieldtosteel.com, www.simonds.cc.