How to Clean Up Cast Iron Machining

This case study explains how Chemtool formulated a novel metalworking fluid with Dow Chemical to clean up the cast iron machining operations of a Midwest machine shop.

Posted: March 20, 2012

Because of their polar nature, PAGs solubilize polar decomposition products, resulting in no varnish or sludge deposits. The non varnishing characteristics of PAGs keep operating systems clean.

UCON™ OSP Base Fluids also overcome a disadvantage of traditional PAG chemistry – incompatibility with mineral oils. Oil solubility expands the versatility of PAG-based lubricants and allows formulators to create new lubricants with unique properties or replace more expensive synthetics with PAG-based alternatives. UCON™ OSP Base Fluids have lowest aniline points in the range of minus 30 deg C to minus 40 deg C which help formulators to solubilize additive components easily and increase the longevity of the finished formulation. Dow introduced UCON™ OSP Base Fluids in 2010 and recently added three additional viscosity grades to the fluid line.

Initial laboratory work by Chemtool suggested UCON™ OSP 680 Base Fluid offered the necessary combination of viscosity index, solvency, polarity and oxidative stability to perform under the conditions in the machining operation. This work also indicated that UCON™ OSP 680 Base Fluid could help meet another important formulation goal – avoid the ongoing need for a tank side additive for residue control.

Chemtool formulated a metalworking fluid containing the OSP Base Fluid as well as PAO in a system with a very low emulsion particle size. UCONTM OSP 680 Base Fluid is an easy product to emulsify, so only a very small amount of surfactant was used, yielding a system with very good wetting, lubrication, and hard water stability properties, even at the higher temperatures typical of the manufacturer’s operation.

PUTTING THE FLUID TO THE TEST

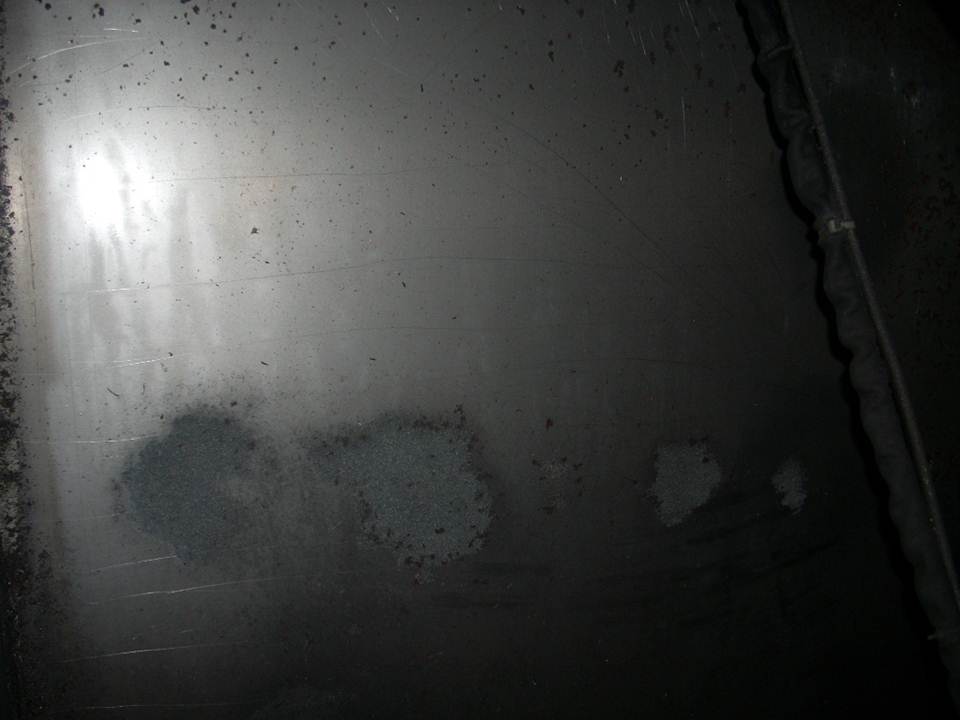

A fluid trial was initiated in March 2010, using a milling machine specially prepared to test residue levels. The back wall of the enclosure, a window and back ways were manually cleaned but residues were left in place on the remainder of the machine surfaces to allow for clear visual comparison of residue build up. Operators reported good machining performance with no real differences compared to machining achieved using the previous fluids.

After two weeks of operation, the cleaned areas of the walls, windows and ways remained free of residue and operators continued to report consistent machining performance. During these operations, tests showed that pH remained very stable.

About two months into the trial, the results remained highly favorable and the manufacturer converted its lathe operations to the new fluid from Chemtool Incorporated. As the test progressed, no additional residue buildup was observed. In fact, the fluid actually began to remove the residues left by the previous fluids, which was due to the inherent detergency characteristic of the UCONTM OSP 680 Base Fluid molecule.

Five months after the trial began, the Chemtool Incorporated fluid based on UCONTM OSP 680 Base Fluid continued to provide excellent performance. No cast iron residue buildup was noted on walls, tooling or chucks. Results were especially good on lathes, where no buildup was noted, even on chucks that had been plagued by residue.

PROMISE OF FUTURE SUCCESS

Dr. Govindlal Khemchandani, a senior technical specialist for lubricants at Dow Chemical, said “We’re very pleased with the results that Chemtool has achieved for their customer with their formulation based on UCON™ OSP Base Fluid. We believe these innovative fluids represent a breakthrough in PAG base fluid technology that creates numerous options for formulators to create the next generation of products, which can leverage the advantages of PAGs with hydrocarbon oils in semi-synthetic systems capable of addressing difficult application challenges.”

Chemtool Incorporated, 801 West Rockton Road, Rockton, IL 61072, 815-957-4140, info@chemtool.com, www.chemtool.com.

Dow Chemical Company, 800-447-4369, www.dowosp.com.