Art Sculptor Uses Laser Scanning to Generate Revenue

NVision, Inc. (Coppell, TX) is helping sculptor Somers Randolph gain additional revenue by laser-scanning his creations and saving them as computer models that can be used later to reproduce the original works at any size on a 3D printer. For…

Posted: March 20, 2012

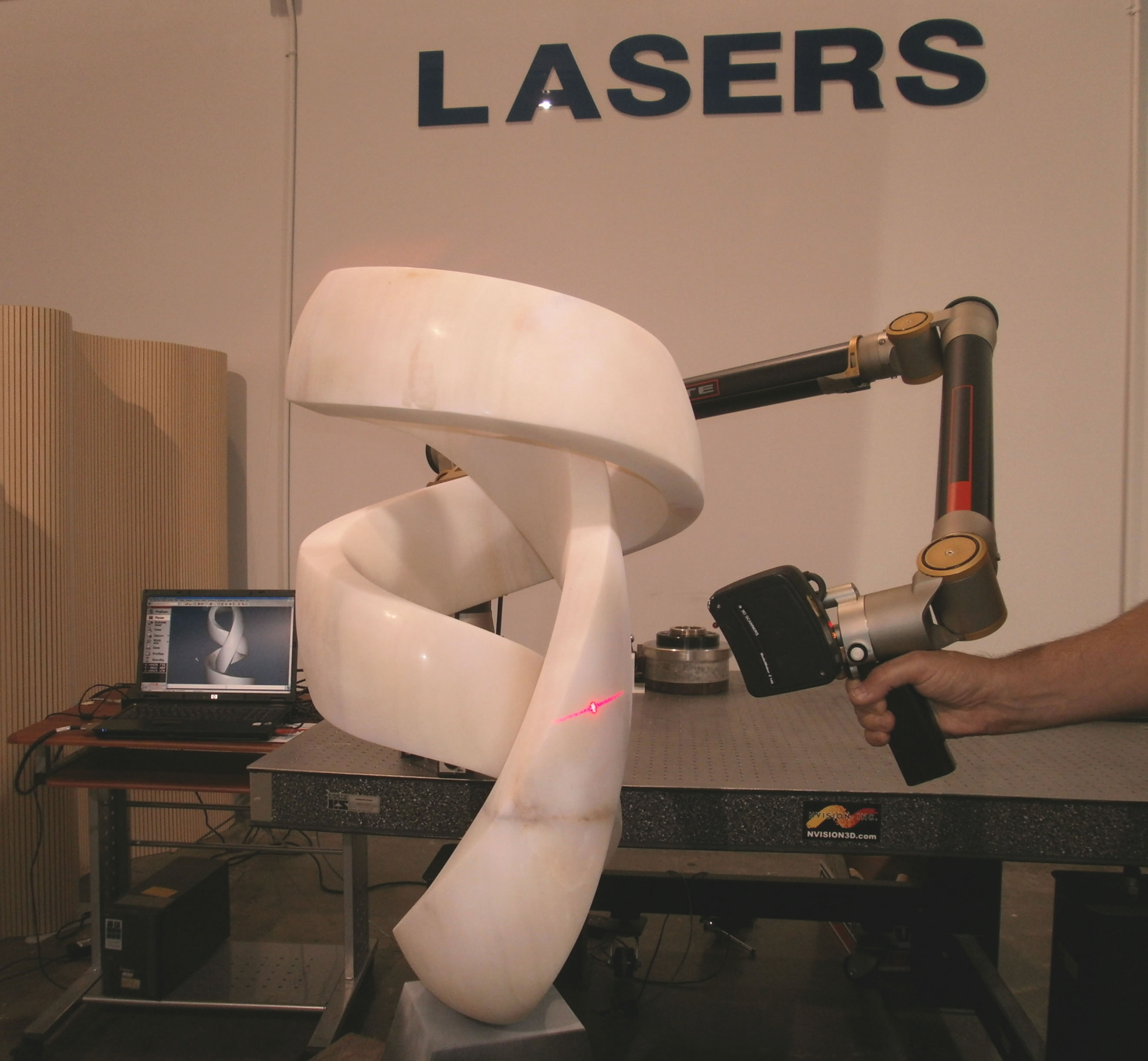

NVision, Inc. (Coppell, TX) is helping sculptor Somers Randolph gain additional revenue by laser-scanning his creations and saving them as computer models that can be used later to reproduce the original works at any size on a 3D printer. For example, Randolph’s wife Hillary has created a successful line of jewelry based on soapstone shapes that Randolph whittled in his spare time. Once these hand-crafted shapes are laser-scanned, duplicates can be produced with the click of a few buttons.

And there will no doubt be demand for those reproductions. New Mexico Traveler Magazine says: “Santa Fe master stone sculptor Somers Randolph combines creativity, skill and passion to create exquisite artwork from stone and to whittle the intricate forms for his line of fine gold and silver jewelry . . . when creativity combines with technical abilities the result is a superb mastery of materials.”

“I often spend two to three months creating a shape in marble or other stone,” notes Randolph. “But for 30 years, once I made and sold them, they were gone forever. Although technically I still own the forms of all the sculptures I’ve sold, in the past it was never practical to store or reproduce them.” The success of his wife’s jewelry line got Randolph to thinking about the value of the shapes he creates and the need to preserve them. Through research he discovered the technology of laser scanning, which makes it possible to create a computer model of a physical shape regardless of its complexity, which can later be used to reproduce the shape to an extraordinary level of accuracy.

“I selected this laser scanning service because they can easily handle any size shape I send them – from the largest to the smallest – provide fast turnaround, and are affordable,” says Randolph. “Their people took the time to help me understand the laser scanning process and worked with me to understand what type of output I needed to ensure that my work would be preserved.”

NVision’s laser scanning works by projecting a line of laser light onto the surfaces to be measured while a camera continuously triangulates the changing distance and profile of the laser line as it sweeps along. The position and orientation of the scanning head is also continuously monitored by a highly accurate localizing device as the data is captured. Instead of collecting points one by one, the laser scanner picks up tens of thousands of points every second. This means that digitizing even the most complicated parts can often be accomplished in an hour or two.

“I look forward to scanning all of my best sculptures,” smiles Randolph. “The computer model they use makes it easy to reproduce the shapes, either in plastic with a 3D printer or as a bronze casting. I feel good knowing that the computer models will forever preserve these shapes for whatever uses I or my heirs can imagine in the future.”

NVision was established in 1990 with one goal in mind: to provide customers with the highest accuracy non-contact optical measurement systems and services for reverse engineering and inspection. Focusing their expertise on the aerospace, power generation, and oil/gas industries, the company provides both contract scanning services and systems sales to manufacturers throughout North America

Their team of engineers provides customers with an unmatchable level of experience and is able to advise and assist with the most difficult engineering challenges. Clients include industry leaders such as Alstom, Boeing, GE, Lockheed, Lear, NASA, Porsche, Raytheon, Siemens,Toyota, and every branch of theU.S.military.

NVision, Inc., 440 Wrangler Drive, Suite 200, Coppell, TX 75019, 972-393-8000, Fax: 972-393-8002, sales@nvision3d.com, www.nvision3d.com.