Bending Aesthetics: When the Finish Comes First

Sometimes marks caused by the lower die during the bending process can turn a good part into scrap metal, even if the scrapes are very light and have no functional bearing on the part whatsoever. To deal with this problem, it is necessary to reduce or eliminate the movement of the material over the hard shoulders of the die. Here are several ways to do this.

Posted: April 9, 2012

One issue I have come across many times in the years I have worked with sheet metal bending applications is the need for a flawless finish on bent parts. When we think about aesthetic bending, the first things that usually come to mind are stainless steel kitchen equipment or architectural pieces. For OEMs that produce these types of products, finish is absolutely critical.

Home owners and businesses alike expect bent stainless units with a perfect polished or grained finish. Even the slightest marring is unacceptable. For food service units, scratches, dents and scrapes are places where food particles and bacteria can collect and make proper sanitation more difficult. From that perspective the quality of the bend moves beyond mere aesthetic attributes and into functional implications as well.

Aside from the obvious need for manufacturers to produce stainless and aluminum parts without scratches, many types of contract manufacturing work call for bending without marring. In cases where the application allows for it, cutting and bending pre-painted material is cheaper than sending finished parts to paint. The ability to handle parts without marring them may also eliminate the need for secondary finishing operations.

There is one cause of marring that fabricators encounter most often: the marking caused by the lower die during the bending process. Whenever you bend material on a V-die, that material is forced to slide over the die shoulders as it is pressed into shape. This sliding action will create distinctive twin scrape marks on either side of the bend radius where the material makes contact with the die. These scrapes are often referred to as “witness marks” since they bear witness to the bending process.

In some cases these marks can turn a good part into scrap metal, even if the scrapes are very light and have no bearing on the function of the part whatsoever. To deal with this problem, it is necessary to reduce or eliminate the movement of the material over the hard shoulders of the die. Fortunately for fabricators taking on these projects, there are several ways to do this.

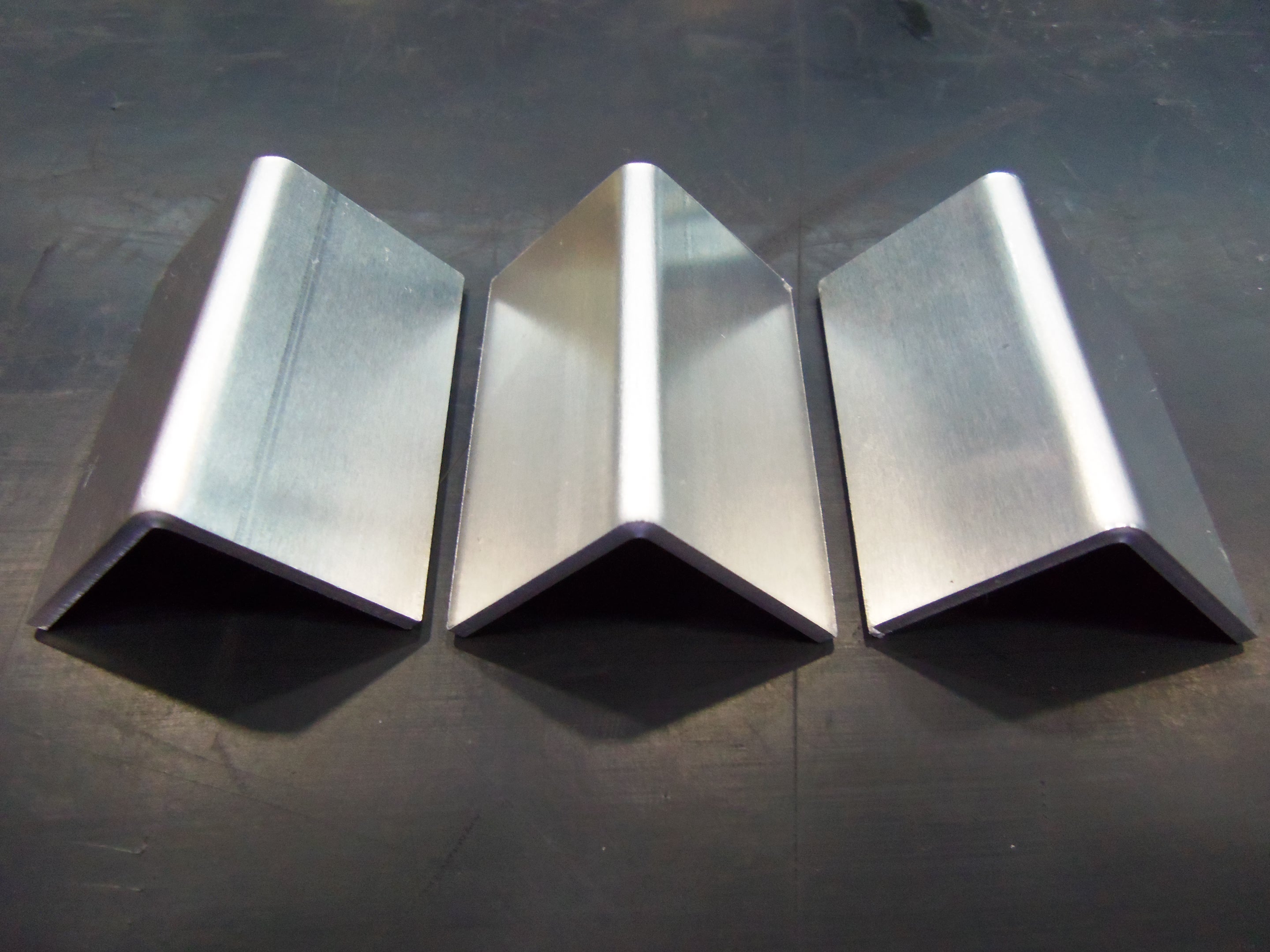

The most common solution is to utilize some type of die-covering material. These materials take the form of a strip which is laid over the top of a V-die to separate the part from the tooling during the bending process. Several varieties are available from different suppliers, the most common being some sort of rubber, though woven cloth materials are also used. Any of these products will prevent marring of the material during the bending process, but some are better in practice than others (see Figure 1).

All of them must be fixed to the lower die to prevent them from sliding around during bending and becoming a hassle. They are usually secured to the die with a couple pieces of tape, which adds setup time and costs to the job. The rubber materials also present a problem for operators because they wreak havoc on angle corrections.

The rubber material compresses during bending and also wears out quickly over time, all of which has the effect of changing the way your parts form from one piece to the next. Rubber materials are simply not very durable. After so many bends the material will tear, at which point it becomes garbage.

At the other end of the spectrum are woven cloth materials that are usually made from some very tough fiber like nylon. These cloth products are usually a little more expensive than rubber, but they do not compress during bending (better for the operator!) and they last much longer, meaning you get more value out of it before you throw it away.

Whether you look into rubber or cloth die guarding products, you will still be looking at extra setup time for your operator. The ultimate solution is tooling-based: utilizing press brake tooling that is designed to minimize or eliminate marking. Tooling-based solutions avoid adding extra setup work for the operator, are more durable than disposable solutions, and will result in more consistent bending relative to die guarding material.

Three types of tooling-based solutions are commonly available from tooling suppliers. The first type (and my least favorite) is a lower die that has replaceable plastic shoulders, as opposed to hardened steel shoulders. This type of tooling can eliminate marring, but the plastic shoulders will wear relatively quickly. True, they are replaceable, but the wearing of the die shoulders will still present your press operator some headaches, as it will cause your angle corrections to shift over time.

Another solution is to use a V-die with a larger shoulder radius than what you would typically use. Similar to punch radii, most tool manufacturers produce the same size V-dies with different shoulder radii. Going from a .040 in shoulder radius to a .125 in shoulder radius will reduce the friction between the material and the die during bending, which in turn reduces (but does not necessarily eliminate) the marring of the part.

The best tooling-based solution in my experience is a rolling V-die, a die that has two cams on top of it. The cams are generally spring-loaded and sit flat when the die is at rest (making it look rather like a flattening die). When the punch presses the material into the die, the cams “roll” down with the material into the shape of a V, and when pressure is relieved the springs pull the cams back to the flat position (see Figure 2).

These tools are mostly intended for bending flange lengths that would normally be too short for a standard V-die. These dies also help with forming bends where there is a hole or contour close to the bend radius that would pull out of shape or distort during the bending process.

A handy side effect of the way this tool works is that it almost completely eliminates the sliding of the material across the die during bending. Because the die shoulders move with the material, there is no scraping and no witness marks.

Mechanical tools like this are more expensive than hard tooling, but the many benefits provided by this type of tooling means that it should pay for itself quickly.