Old Habits Must Die Hard

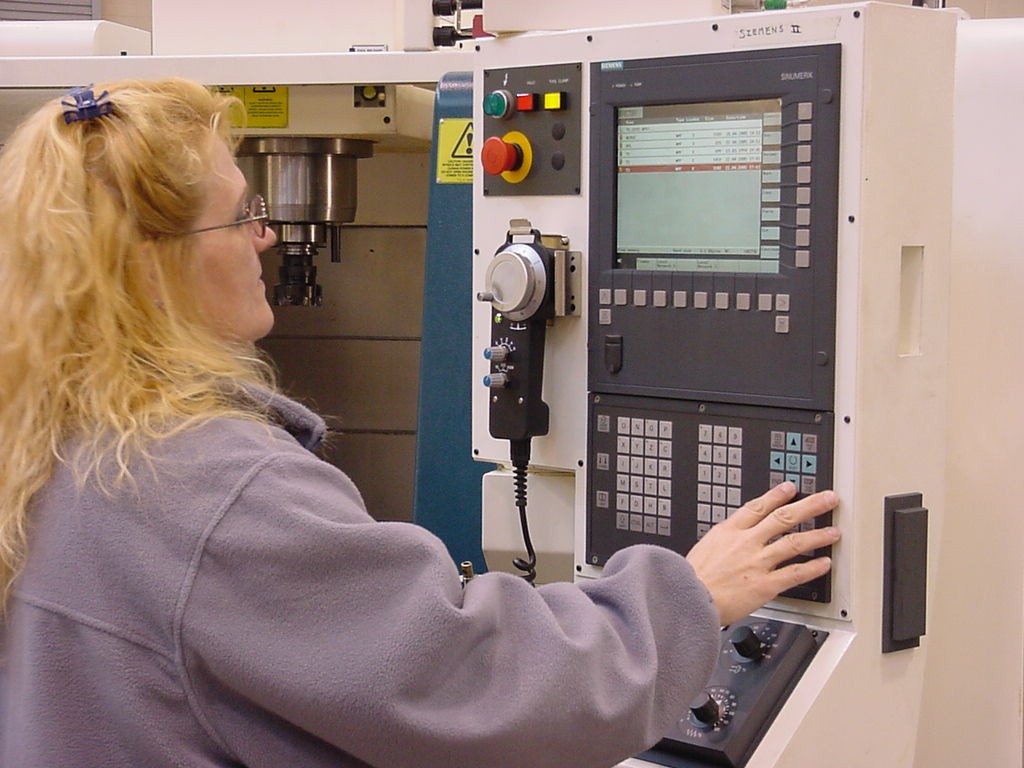

The number of experienced machinists in the U.S. is declining, but all shops that seek operator efficiency can still achieve it through the education programs offered by machine builders and control suppliers alike.

Posted: May 9, 2012

We’ve all heard about tribal knowledge and it certainly has its place in the real world of machine shops. Those experienced machinists that possess the hands-on experience of using and dealing with sophisticated controls, drives and set-up devices, as well as quality checking instruments in their shops, are invaluable sources for knowledge and practical problem-solving strategies.

When they talk to the next generation of machinists, they are simply talking to themselves a generation ago. Despite the advancements in computer technology and the ways young people sometimes occupy their time (i.e., playing video games instead of reading Popular Mechanics), there is one very special characteristic that is common to all machinists: It is the need, maybe even the passion, to use a tool to make something.

By imparting the how-to knowledge from one generation to the next, tradesmen of all types have prospered throughout the centuries. Good training does indeed often occur by one operator showing another how something gets done better, faster and more efficiently. Nothing can replace the intuitive process adjustments made on a specific machine tool by an acute ear that knows what to listen for, the fingertips that tweak just enough . . . right on time, every time.

However, the well-known problem facing many shops now with this traditional “passing of the torch” is that the number of experienced machinists in the U.S. is declining and their inherent pool of knowledge is slowly drying up. But there is another source of knowledge that is available and it’s one that far too often ends up a low priority at many shops: The training offered by votech schools, machine tool builders and the manufacturers of those sophisticated computer controls.

The truth in today’s ultra-competitive manufacturing environment is that the best training also requires parallel simulation of a CAD program operation, workpiece set-up, machine cycle or tool change strategy outside the envelope of the shop work cell. This offline instruction can be – often must be – a precursor to the start-up of an operator’s work life. For any shop owner to think this activity is a low priority simply means that shop will be at a competitive disadvantage in the future.

The simple fact is that technology continues to ramp up at a very fast rate and “the way we’ve always done it” just won’t work anymore. Shops of all types have been documented to realize a 20 percent or better improvement in their performance – from the very first part – when a machine tool and its controls are properly and fully utilized.

Likewise, the machine tool builders and controls suppliers can improve their own bottom lines by providing the votech schools and their own training facilities with the very latest technologies. How? This alternative method of education generates more brand-loyal CAD and machine operators with practical know-how who enter the market better prepared at what they do.

Our industry needs to realize that training is not a cost, it’s an investment. And this is an investment that we all need to make if our industry is to “pass the torch” for the next generation to remain solvent in the U.S.