The Ins and Outs of Punching Technology

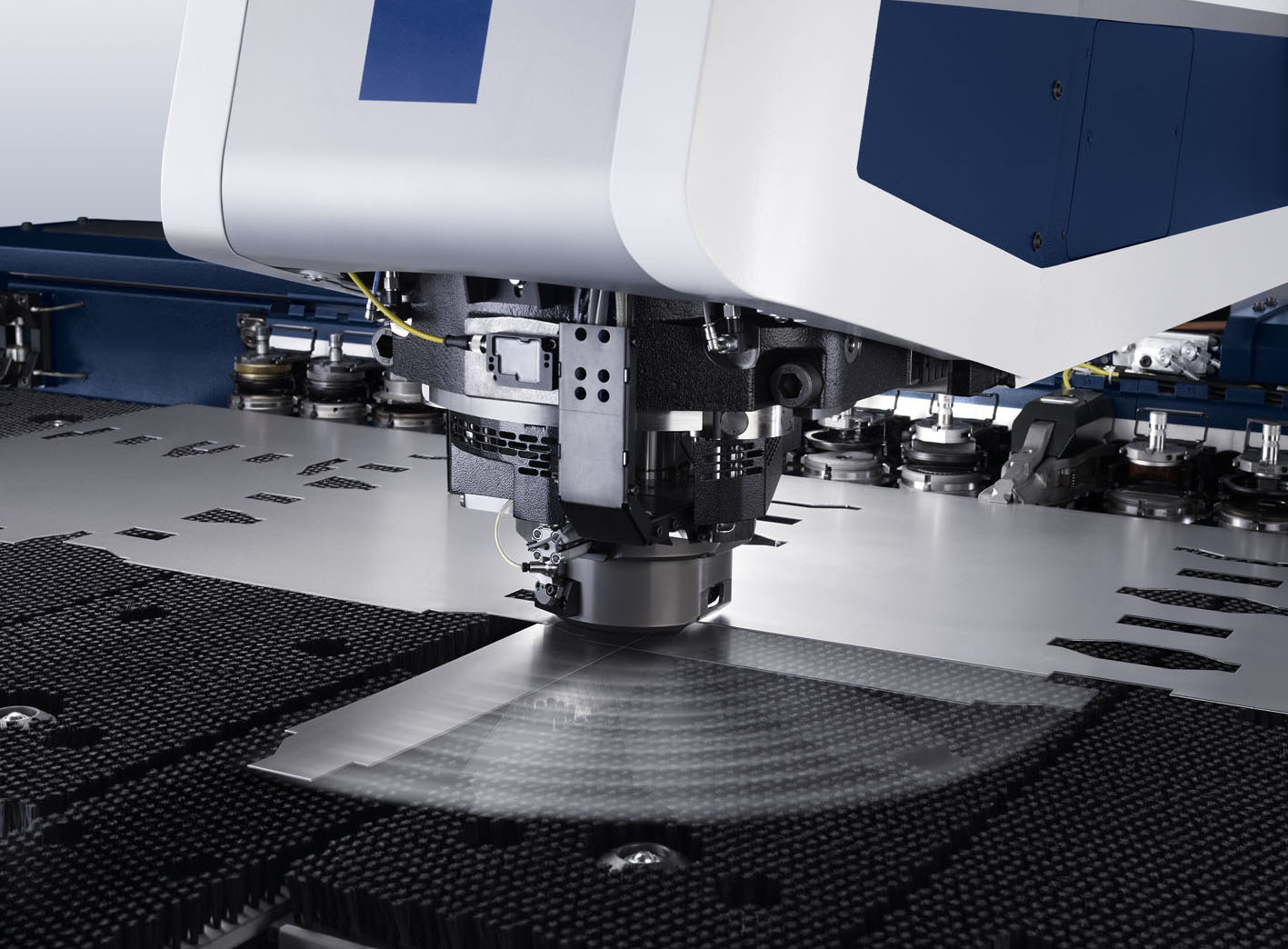

Punch machines now do much more than simply punch holes. Today it’s all about completing multiple processes on the same machine, such as making up to one inch high flanges, tapping holes, forming, extruding, ribbing, offsetting, removing burrs from parts and more.

Posted: June 6, 2012

Traditional steel applications are everywhere around us: in vehicles ranging from automobiles, trains, trucks and trailers to farm combines to lawn and tractor equipment; in indoor exercise equipment, lamps, lighting and indoor furniture; in construction materials; in military applications and much more.

Aluminums are softer types of material and can be used when magnetic applications are a concern and secondary coatings are not required. Aluminum is also lighter in weight, making it very attractive for fuel economy opportunities in various transportation applications.

Most aluminum is pliable and more easily compressed and formed compared to steels, making them ideal for countersinks, counter bores, lance and forms, and dish-form type of applications. As a softer material, scratches or tool marks from the punching machine will be more evident and pronounced. Aluminum material is widely used in everything from commercial transportation and aerospace to outdoor furniture and other processes where multiple forms are needed.

Stainless steel is one of the more difficult materials to punch and is often used where the strength of parts is necessary for a specific application. Tapped holes are often found in stainless steel due to the higher tensile strength of the material and the ability to withstand repeated removal of threads without wear. Louvers are also common because this material is resilient to rust and can easily be sanitized, making it an ideal candidate for food service and medical applications. The appliance industry is also a perfect example of where stainless steel is well utilized.

Without question, punch machine technology has evolved throughout the years. Yet limitations do still exist: Challenges include material thickness, part edge quality and sheared edges that are still evident with processing parts on a punch machine. Materials also play a factor in this process. Armor plate, hardened steels, and materials with Rockwell hardness greater than the punch tools used to process the material make it impractical to process on a punch machine. This is why fabricators must choose wisely when determining the types of parts they schedule for work on a punch machine.

The latest punching technology gives fabricators the opportunity to process up to 1 inch high flanges, tap holes, form, extrude, rib, offset, and remove the burrs from parts. These machines are still commonly used for thinner gages of materials. Fortunately, in this day and age, fabricators have a wide variety of equipment and options to meet their application requirements. With a little research you can be assured to find the right solutions to meet your business challenges.

The power of choice in the market today allows you to select wisely for your current and future processing needs.