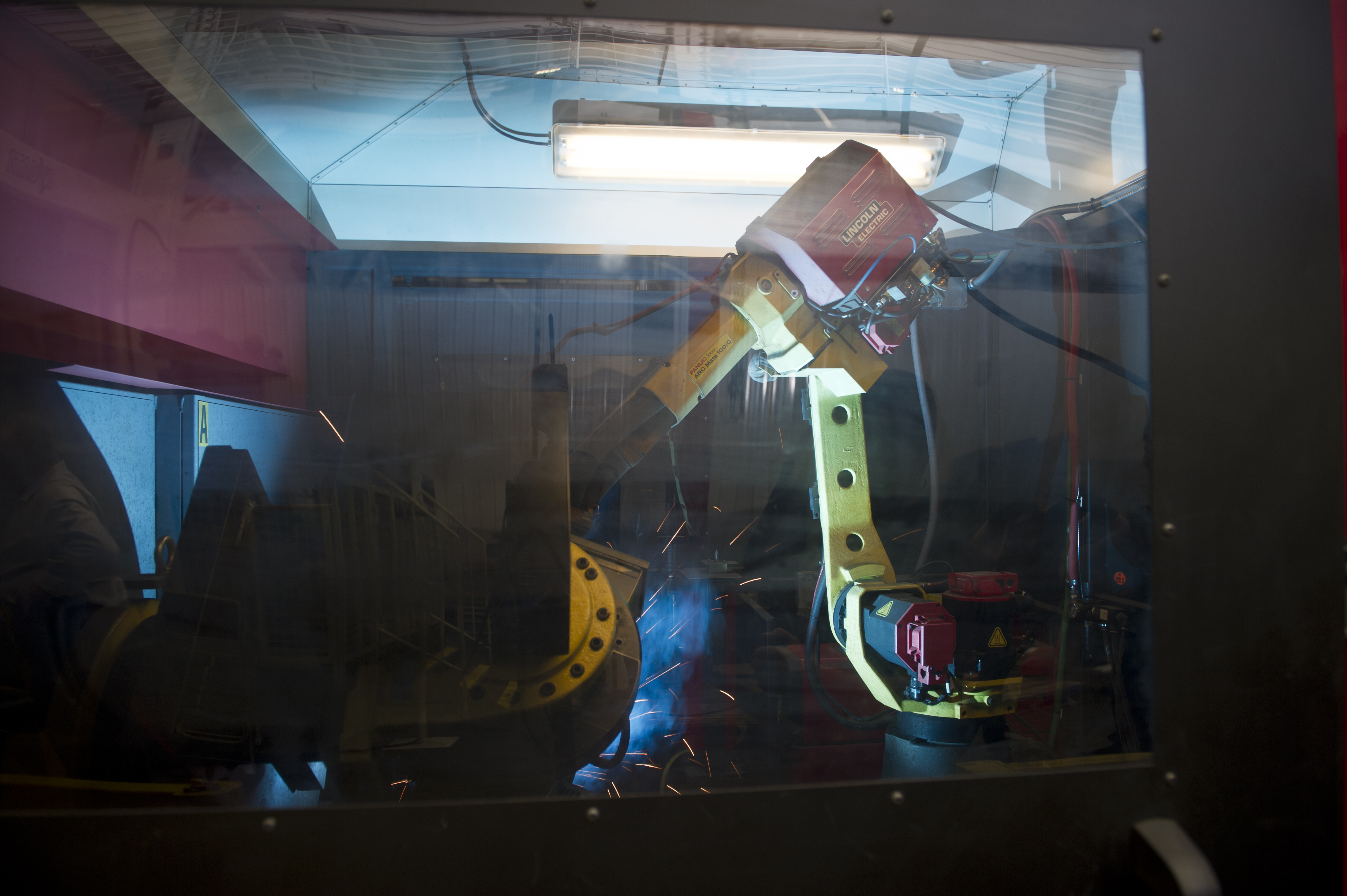

Automated Welding Increases Productivity

The Franklin plant of mining equipment manufacturer Joy Mining increased productivity and reduced costs in their bit block assembly by converting to automated welding systems from Lincoln Electric.

Posted: September 26, 2012

In today’s highly competitive industrial manufacturing environment, it’s crucial to run a cost efficient, reliable and productive fabrication line that yields durable, rugged, high-quality products. At Joy Mining Machinery, a global leader in the development, manufacture, distribution and service of underground mining machinery for more than 90 years, the desire to continue to achieve this goal drove the company to upgrade the welding equipment at its Franklin, PA, facility.

Joy Mining Franklin has earned a global reputation for the quality and durability of the products it manufactures. All products are distributed and supported by the company’s 46 facilities, located in eight countries around the world – Australia, India, China, Poland, Russia, South Africa, the UK and the U.S.

http://youtu.be/649dZPCTD30

Welding is an essential step in the Franklin facility’s production of longwall and continuous miner systems used for the underground extraction of coal and other bedded materials, such as salt, potash, gypsum and oil shale. Longwall mining accounts for about 50 percent of global underground mining production, while continuous mining covers about 45 percent. The company recently moved a portion of its semi-automatic welding systems to automated GMAW (MIG) welding for the bit block and pedestal assemblies produced at the Franklin plant for these mining systems. These assemblies hold the massive, custom bits that drill into the rock surfaces in underground mines.

THE WELDING PROCESS

According to Craig Cerminara, the A&R welding engineer at Joy Franklin, the company sought to move 98 percent of the bit block-to-pedestal welding activities to an automated system from semi-automatic MIG welding.

At this station, workers attach bit blocks made from treated, air-hardenable steel to a carbon-steel pedestal via semi-automatic MIG welding. One welder can fabricate between eight and 10 bit blocks in an eight-hour shift. Each of the plant’s three shifts have six to eight welders at the bit block station, welding the assemblies and adjusting the angle radius of the block, depending on the customer’s specifications. Shop management knew it was time to streamline the process while increasing the production rate.

“All businesses face challenges in today’s economy, especially those in heavy manufacturing. Obviously we were looking at as many different solutions as possible to make necessary process improvements. First and foremost, we were seeking to increase our productivity and reduce costs, while maintaining quality manufacturing,” notes Cerminara. “Automation was one option that really stood out to allow us to introduce a more modern solution to our bit block-to-pedestal welding process. We weld a great number of these parts, and they lend themselves well to automation, so we decided to seek a custom solution to help us achieve this.”

DETAILED METRICS AND EVALUATION

To ensure that the company would find the right integrator to match its automated welding needs, Cerminara and his team put together a detailed evaluation system to compare manufacturers, their products and their services, evaluating each supplier’s offerings and abilities on 32 different metrics. “The metrics were designed to measure and compare each of the integrators against one another for all of the services and specialties we thought would be important to support Joy as a company,” Cerminara explains, noting that some of the key metrics included the following:

- Demonstrated ability to provide “complete support” for the automated system

- 24/7 technical support

- Overall integration of the cell

- Cost of the system

- Weld quality

“Many of integrators we were considering scored very well on all of the metrics, but in the end, the Automation Division of Lincoln Electric (Cleveland, OH) scored the highest and was the best fit for what we wanted to do here at Joy Mining,” Cerminara notes. Cerminara adds that Lincoln Electric fared well in a number of the metrics, citing such factors as accurate cycle time estimates, overall system cost and the willingness to provide ongoing support for the custom system after installation. These were three leading reasons why they won the contract. But other influences also figured prominently into the decision as well.