Automated Welding Increases Productivity

The Franklin plant of mining equipment manufacturer Joy Mining increased productivity and reduced costs in their bit block assembly by converting to automated welding systems from Lincoln Electric.

Posted: September 26, 2012

Beyond internal process improvements and savings, Joy Mining also wanted to remain dedicated to providing the global mining industry with products that would hold up to harsh underground environments and heavy use – anywhere on the map. “When we were making our decision on which automated system to use, we also took into account the global reach of the supplier we selected,” Cerminara says. “Their ability to provide support around the world was another contributing factor.”

Also coming into play was the fact that Joy Mining Franklin has been a 100 percent Lincoln Electric shop since 1998. Welding stations throughout the plant feature such multi-process welders as the Idealarc® DC-600, Idealarc® DC-655, and Invertec® V350-PRO, LN-10 and DH-10 (dual head) semi-automatic wire feeders, advanced process Power Wave® 455M power sources as well as Precision TIG® 275 stick/TIG welders for general welding and fabrication of other mining equipment components.

The shop also uses a pre-engineered automated system from Lincoln Electric to perform etching of serial numbers and other alpha-numeric information on various parts manufactured at the plant. Prior experience with this system helped Cerminara become familiar with the capabilities they could provide when offering a custom automation solution. “We wanted an integrator that would take responsibility for all aspects of the system, not just the robot,” Cerminara explained. “We already had a history with their welding systems and knew the company would step up in any situation and take care of any challenges and necessary troubleshooting.”

SYSTEM SPECIFICATION

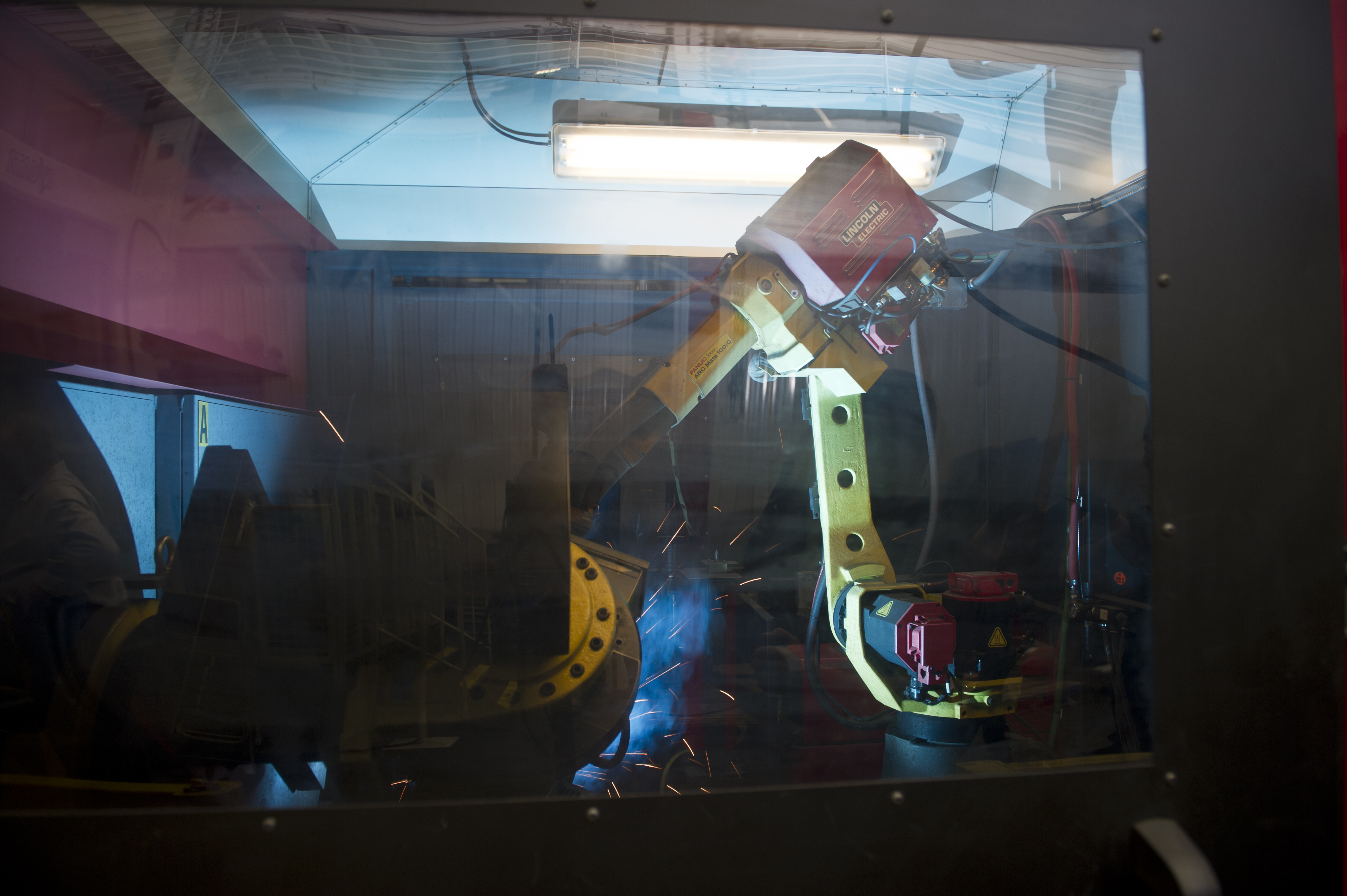

After reviewing the results of their metric evaluation, Cerminara and his team decided to replace nine semi-automatic Idealarc® DC-655/LN-10 stations used for bit block-to-pedestal assemblies and install two automated welding stations in their place. The custom-designed solutions feature Power Wave® 455M high performance, inverted-based welding power sources, FANUC ARC Mate® 100iC robotic arms, and Harris® Preheat Torch systems and temperature-sensing devices. The systems use SuperArc® L-56 premium mild steel MIG wire in 0.045 in (1.1 mm) diameter.

The preheat torch and temperature-sensing devices were important features. During the fabrication process for the bit block assembly, the part must be heated to 300 deg F (149 deg C) but cannot exceed 500 deg F (260 deg C), so it is necessary to check the temperatures before welding and also during the weld cycle to ensure a quality, durable weldment. “This configuration is unique to the application,” notes Marty Siddall, the technical sales representative and automation specialist who assisted Joy Franklin in developing its custom welding solution. “The entire process is fully automated and regulated.”

PROCESS IMPROVEMENTS

Once the automation system started making production welds, Cerminara and his team were able to track notable changes in productivity. To date, the conversion to automated welding has resulted in an 8 percent increase in bit block-to-pedestal assembly productivity. Additionally, it has saved more than 12,000 hours of work annually.

“We can now weld the same number of assemblies with one operator running both stations per shift. In the past we needed between six and eight welders to manually produce the same number of parts. But using automation, we need only three operators per day vs. the 18 to 24 required in the past,” explains Cerminara. “Automation has made the difference we thought it would. When you look at the productivity increase, the return on investment and other numbers, all of those metrics have been met or exceeded with the installation of the automation equipment. Overall, the results have been spectacular.”

Beyond the obvious boost in productivity and related cost savings, Cerminara also cites the support that was provided continually during the planning, installation and transition to the new system and on a day-to-day basis now that the system is up and running. This support was a valuable benefit of the partnership and is something the company remembers as it plans future expansion into automated welding in other areas of its manufacturing process.

“We have been extremely happy with the depth of ongoing support of both the sales team and the project lead,” Cerminara says. “As we go forward with additional automation solutions, we’re confident that we’ll continue to identify opportunities for process improvements and are implementing them as time permits. It has been a best-in-class experience.”

Joy Mining Machinery, 177 Thorn Hill Road, Warrendale, PA 15086, 724-779-4500, www.joy.com.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 216-481-8100, Fax: 216-486-1751, info@lincolnelectric.com, www.lincolnelectric.com.