Solid Wire vs. Metal Core Wire, Revisited

In terms of welding costs, the choice between solid wire and metal core wire is not a simple one. Here’s why it all boils down to perspective.

Posted: December 3, 2012

One reason for this is that the average contact-tip-to-work distance (CTWD) used for these wires is about 1 in, so a high level of radiated heat will be transferred to the welder’s hands and body. This is one of the reasons that the Innershield® welding process is frequently utilized for high deposition rate welding, as some electrodes (such as Innershield NR-305) utilize CTWDs longer than 2 in.

Another reason is that the travel speed will be required to be extremely fast (17.5 ipm travel speed at 17.5 lb per hour deposition rate and 21 ipm travel speed at 21 lb per hour deposition rate), so it will be difficult for the welder to consistently focus the welding arc at the root of the joint. At these high energy procedures, robotic and/or automatic welding machines would most likely need to be utilized.

So, one may ask the question: Which wire is “higher in deposition?” The answer based on the argument above is that it depends upon at least two factors: (1) the output amperage used and (2) the welder’s skill.

At relatively lower amperages, .045 in metal core wire is shown to have a higher deposition rate than .045 in solid wire at equivalent output amperage. At higher output amperages .045” solid wire begins to shine, as its useable operating range is higher compared to metal core. Therefore, if robots or automated welding equipment are available, then .045 in solid wire becomes a more attractive choice in regards to throughput.

Let’s assume, however, that automated welding equipment is not an option and that all welding must be done by hand. Despite the fact that .045 in metal core may have a higher melt-off rate compared to .045 in solid wire at the same output amperage, one could argue that this is irrelevant. If the fabricator requires a deposition rate of 18 lb per hour, this can be achieved with either .045 in solid wire or .045 in metal core by simply turning the wire feed speed up or down (since we removed any power source restrictions earlier). Now the attention has once again turned to total cost per pound of deposited weld metal.

Intuitively, one might be tempted to compare consumable costs to determine which electrode will provide the least expensive welding process. After all, welding wire is purchased by the pound. And, at the deposition rates we just examined, the efficiencies of both electrodes are approximately the same in the spray transfer. So the least expensive electrode should result in the lowest cost of weld metal per pound, right?

This should be starting to sound familiar. If we harken back to last month, we might remember that electricity costs can play a significant role in total welding costs. In that situation, it was stated that electricity costs on average comprised about 2 percent of the total cost of welding. However, in this specific case, the electricity required to deposit a pound of weld metal is much greater with .045 in solid wire than it is with .045 in metal core. This is due to the higher current density of metal core wire.

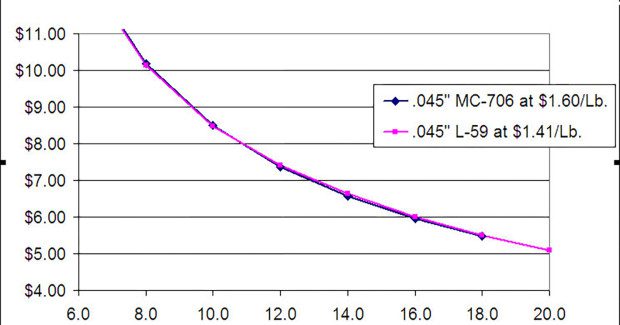

Since the electricity costs associated with solid wire are higher than those with metal core, there must be a break-even point. Exactly how much less expensive must the .045 in solid wire be so that the total cost per pound of deposited weld metal is the same between the two electrodes? The legend in the nearby graph shows that .045 in solid wire must be discounted by $0.19 in order for the total costs to be equal – regardless of the deposition rate. This means that if the cost per pound of .045 in metal core wire is $1.60, then the fabricator is losing money if he pays any more than $1.41 per pound for .045 in solid wire.

The choice between solid wire and metal core wire is not a simple one, and boils down to perspective. Metal core wire has a higher deposition rate per output amp until its limits are reached. Beyond that, solid wire has a clear advantage with its higher useable range, but this may be too hot to handle for the average welder. And from a dollars and cents perspective, in order to achieve an identical cost per pound of weld metal, solid wire must be purchased at a discount per pound compared to metal core due to its inherently higher electricity costs.