How to Use High Feed Milling on High Strength Steel

When Ace Precision Industries moved their conventional tooling and methods to a new HMC, the process worked but they could not optimize their new machine tool capabilities. By switching over to high feed milling, their machining costs dropped like never before.

Posted: February 11, 2013

Ace Precision Industries Inc. (Akron, OH) produces several variations of small components for mining equipment, such as cowl arms, and traction reducer cases. These parts comprise one facet of a diversified product mix that includes babbitted bearings and compressor components, as well as machined components for the mass transit, petroleum and off-road equipment industries.

http://youtu.be/aXa6p77uXlw

Relationships are important to Ace, and manufacturing manager Tom Stugmyer has been with the company since 1988. Throughout his tenure at Ace, distributor George Whalley Company (Cleveland, OH) has been a one-stop resource for his shop’s tooling needs with a long-standing sense of trust between the two companies.

Ace invested in a single spindle Niigata HD80 horizontal machining center that would enable them to run larger parts with high feed/speed capabilities. They initially transferred the conventional tooling and methodology they had been using for ten to 15 years to this new equipment.

The process worked but was not optimizing the capabilities of the Niigata HMC. Larry Wragg, the George Whalley representative, in tandem with Tom Batchelor, a Seco Tools (Troy, MI) application expert, suggested that the shop try a using a Power Turbo heavy duty square shoulder mill designed to provide maximum metal-removal with free-cutting inserts.

“The cowl arms are made of A514 steel that is flame-cut to shape, and the hardening caused by this process has always made these components tough on tooling,” noted Stugymer. “We were eager to make improvements.”

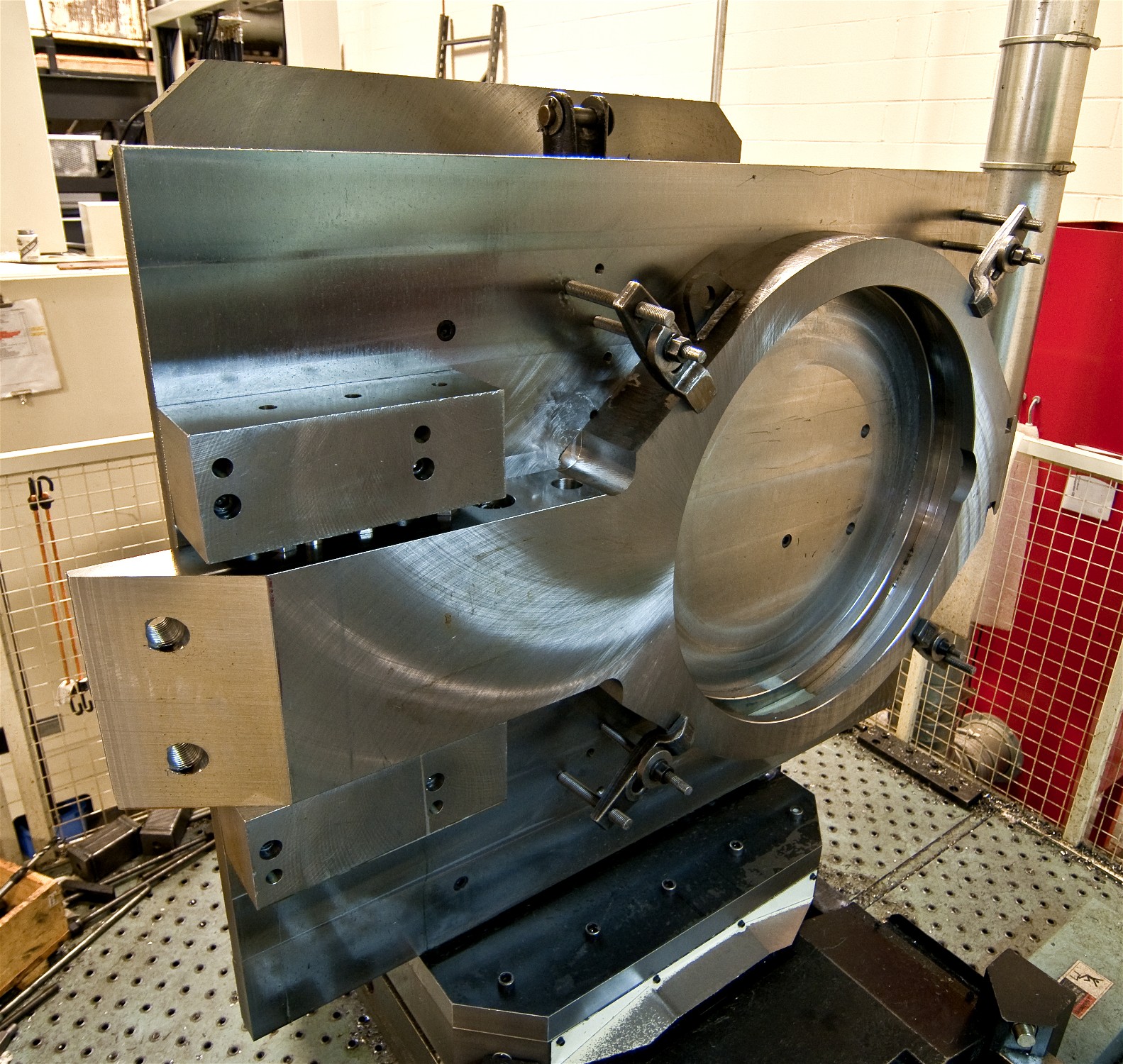

The overall size of the part is 62 in long x 34 in wide by 4.5 in thick. There are seven steps required to produce the component. Batchelor initially concentrated on the first step: roughing out of a bore area that is 4.5 in deep with a range of 25 in to 36 in ID. The shop had been using a 32 insert end mill to hog out the metal, which was taking over an hour on average, but they knew this methodology worked.

Given the speed capability of the Niigata and considering the space constraints of the new enclosed machine, Batchelor was confident they could improve the process with a helical interpolation methodology using a high feed milling cutter. In addition to being enclosed, the Niigata machines have internal tool changers that make it nearly impossible to get a big boring head inside the machine.

“Even though conventional wisdom says we should be boring a hole, we can’t get a boring bar inside the machine due to the tool changer,” explained Stugymer. “Hence, our need to develop a more efficient method.”

High feed milling (HFM) removes lots of materials in the fastest possible way, with the cutting forces directed in the axially back into the spindle, meaning this method has an outstanding performance when machining with large overhangs.

“The shop was using was a helical end mill with 32 inserts,” recalled Batchelor. “We applied a 4 in diameter high feed mill using 218.19 insert in a Duratomic grade MP2500.”

With this switch, the boring operation was reduced by over 50 percent, down to only 28 minutes. “Plus,” added Stugmyer, “this cutter only requires seven inserts versus 32, so we cut the machining time in half with only a quarter of the number of inserts.”

Another area where Batchelor thought operations could be improved involved the boring out of two corners for stress relief purposes where the rod connects to the round cowel head. The shop had been machining a 1.1875 in radius using a boring bar, because a correct-sized diameter cutter did not exist for this operation.

To tackle this task, Seco actually made a 2.375 in diameter Power Turbo mill with five teeth for the shop, using the M14 geometry in grade F40M. This new mill reduced machining time from 50 minutes down to 5 minutes!

A plunging methodology was again employed by taking 0.100 in steps in many passes, with no more than .05 in depth of cut/pass to produce a 1.1875 in corner radius. The spindle speed remained consistent at 804 rpm, but the feed rate increased from 0.015 ipr to 0.283 ipr.

Ace can now manufacture about one cowl arm a day. With this switch to Power Turbo, the shop can save about $28,000 per year just in machining cost on the component, and this does not account for the reduced number of inserts now needed to complete the first boring operation.

Ace Precision Industries Inc., 925 Moe Drive, Akron, OH 44310, 330-633-8523, www.acebearings.com.

The George Whalley Company, 18200 S. Waterloo Road, Cleveland, OH 44119, 216-481-1414, www.georgewhalley.com.

Seco Tools North America, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5200, Fax: 248-528-5600, www.secotools.com.