Hot Keys, Sans Piano

CNC function keys now offer advantages to programmer, operator and maintenance personnel alike.

Posted: March 18, 2013

All CNC machine tool screens are generated by either hard pushbutton function keys, onscreen soft keys or a combination function, aka shortcut or hot keys. These are the seemingly basic means of generating data, visualizing a cutting path, examining the cycle steps and, when necessary, capturing the data logs for error evaluation or program modification.

http://youtu.be/llhnU20sz3A

Simple, right? Well, on today’s advanced CNC models you can play quite an application symphony with these hot keys. Among the many combinations now available to help you program, set-up, run and maintain your machine tool are these classics:

- Language – with the touch of a button, your CNC can run in dozens of languages, all pre-loaded as standard. This function is ideal for international facilities who want to standardize their process applications and streamline their equipment efficiencies.

- Screenshot capture – in a malfunction, all of the data can be captured and either filed for emailing or offloaded onto a USB stick or CF card.

- Full cut and paste – this function allows the programmer to quickly enter a program on the machine to make a modification in the tooling, cutting path, fixturing or material selection.

- Saving of a complete archive – an especially useful management function for shift analysis, peer-to-peer machine comparisons and study of other production metrics.

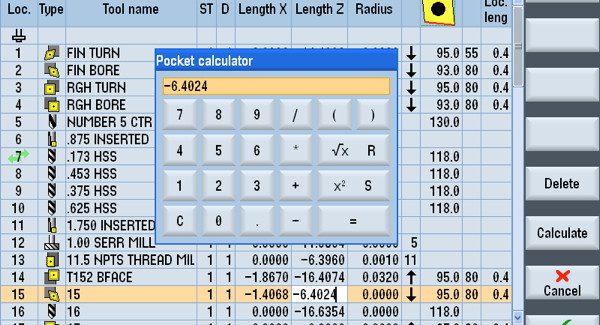

- Pocket calculator – all calculations can be done onscreen, then immediately entered into a program with a single key touch so no time is wasted.

- Simulation/Simultaneous recording – cursor keys can rotate in 3D display, plus sections can be repositioned for part family production, saving huge amounts of time, particularly in the front end of job planning.

Then there are some of the newest advancements:

- Controlling energy consumption – the historical data of a production cycle not only helps dictate the power utilization, but actually powers down select machine components for optimum energy savings on the machine tool, all while providing full data offline for analysis of overhead cost reduction.

- Speed/Slow simulation – another time saver, particularly for precise positioning analysis on complex applications.

- Input of Asian signs – another onboard assist for machine tool builders and end users with international facilities who want to standardize their process applications and streamline their equipment efficiencies.

One of the coolest features of the new generation of hot keys is the procedure walk-thru, whereby a trainer, machine tool dealer or shop supervisor can output a specific program’s steps to a printer, allowing the creation of dedicated training materials for a specific machine, job or family of parts. Also with this feature, part images, fixturing and simulation cycle steps can be easily output to accompany the text for a set-up or cycle procedure. Programmers can also use the hot keys and the onscreen calculator to also make tool offset, work offset and any program parameter changes on the fly.

Now, I know what you’re thinking, to quote a great movie character . . . where’s the safety and security?

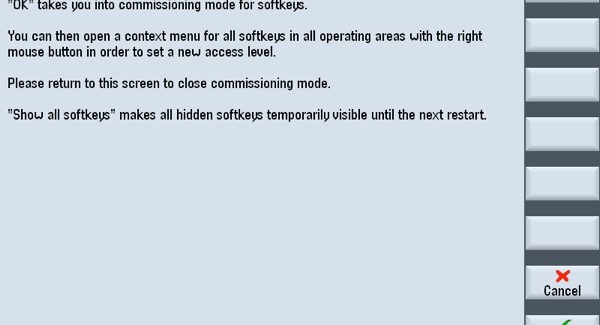

In fact, not only can the hot keys be password-protected on various access levels, but the onscreen soft keys can also be made invisible – except to those entering the proper ID code on the machine control. This prevents the law of unintended consequences from entering the equation. Levels of access can be predetermined for programmer, operator and maintenance personnel alike. Best of all, when the proper code is entered, only the relevant permitted keys are viewable for that unique user ID.

With less need to “navigate” to get to the desired screen shots, owing to these shortcut keys as well as one-key capture of all machine data at any time in any cycle, your shop can be humming along on every tune. In the end, the advancements in key coding and screen appearance are making some beautiful music these days, in shops everywhere.

The Duke or even that Mozart guy would be impressed, I think.