Large Holes, Larger Savings

Big holes don’t mean big bottlenecks anymore, even though some shops still don’t believe a hole can be milled right through solid steel. But R&R Machine proves it by producing big holes faster than twist drilling and with much better tolerances than flame or plasma cutting by using Ingersoll Cutting Tools.

Posted: March 5, 2013

R&R Machine (Talladega, AL) is a six-man job shop that doesn’t take retooling casually and can’t afford to be wrong. Most of their jobs are in the 150-piece range with some, but not necessarily all, expected to repeat. “We have to get it right – and make our margins – on the job at hand,” notes Chris Barnes, the lead machinist in the shop. “We can’t necessarily ‘invest’ in tooling based on a return with the third reorder. We need versatility as well as productivity. For a tool to get in here, we have to believe it will pay off both immediately and in the long run.”

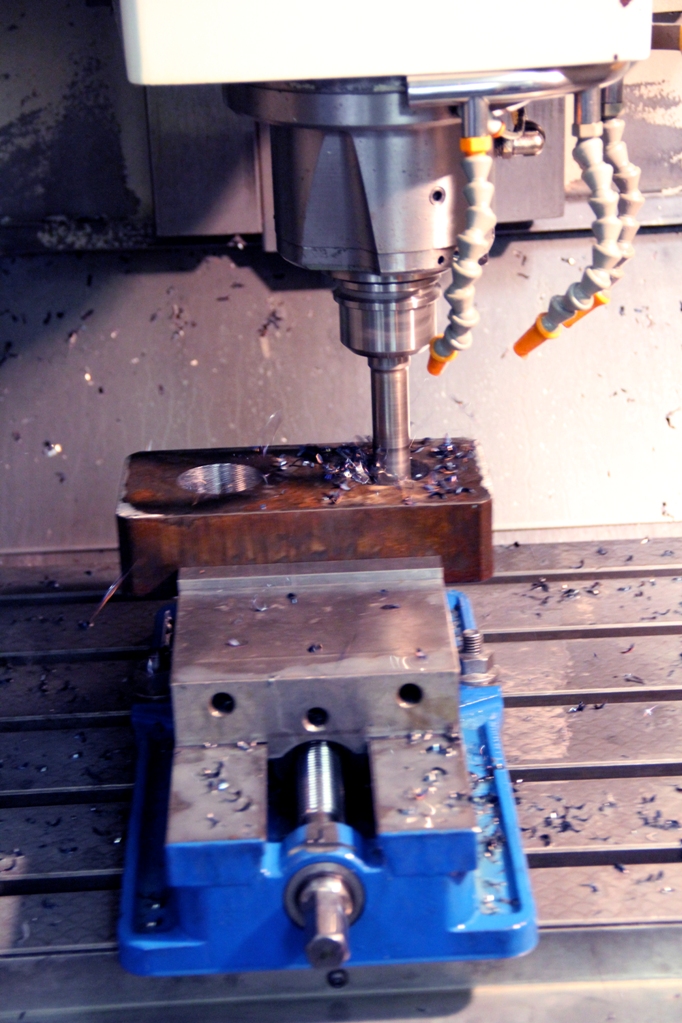

They typically handle a variety of machining work where large-scale holemaking is a big part of the diet on hefty parts that go into chemical processing and off-road equipment. This work taught Barnes something about better ways to open big holes with a light-duty CNC machine. “We are talking about corkscrew milling two-inch holes in thick steel plate on a Fadal 40 taper vertical machining center,” he says. “Twist drilling holes like these could easily stall the spindle or warp the frame.”

By using this vertical corkscrew milling technique, R&R has cut its cycle times on some holes from days to hours and dramatically reduced its tooling costs when compared with either twist drilling or orbital milling of pre-opened holes with a solid carbide endmill.

http://youtu.be/WQF5KZNNkZ8Here is a demonstration of the Form-Master Pro End Mill in roughing and corkscrew milling applications on 4140 steel.

Before this, the standard shop practice had been to corkscrew mill with a three-flute indexable cutter from Ingersoll Cutting Tools (Rockford, IL). “It was working fine as far as I was concerned,” recalls Barnes. Then, thanks to a drop-in retooling, holemaking that once took ten minutes apiece are now done in just one minute.

Triggering this change was Ingersoll field engineer James Wilson who, during a plant walk-through, believed the shop could do better with a later-generation High Feed Mini Mill. Barnes was already sold on corkscrew milling, but the question was how to do it better.

Side-by-side trials on mild steel proved to him how a High Feed Mini Mill could reduce the cycle time to open a 2 in x 2 in hole from nearly 6 minutes down to 90 seconds. Wilson and Jimmy Roszell of local distributor Industrial Tooling & Supply (Anniston, AL) ran the trials and optimized the settings. Feed rates increased to 220 ipm from 50 ipm and feed per revolution rose to 0.072 in from 0.019 in.

In another trial the tool reduced the cycle time for large holes by ten to one – and did it with the same absolutely reliable chip clearance and insert life that R&R had gotten with the previous cutter. When Wilson and Roszell were done, the operation proved totally stable at 800 sfm with a 0.025 in depth of cut. The shop quickly adopted the new cutter with these parameters for all holes 1½ in diameter and larger.

From that point forward cycle time savings have averaged 10 to 1 on a wide mix of work and insert edge life has averaged 50 holes, with predictable edge wear the only failure mode, never anything like catastrophic chipping or rupture.

What physical differences between the two indexable mills accounted for R&R’s big gain? “The main difference is insert geometry,” explains Wilson. The new inserts are curved with a large radius, are seated with a backtaper, and have a helical cutting edge. This combination enables higher feed rates, creates a gentler entry and adds more axial cutting forces. The tool can plow ahead with virtually no risk of lateral deflection.” He adds that the insert’s fourth flute (vs. the previous three-flute design on the other insert) spreads the cutting forces more widely, permitting higher material removal rates without raising chip loads.

“One caution, especially in a vertical setup, is to be certain of a very high flow of coolant or compressed air,” advises Wilson. “The cutter geometry itself may cut fast and reduce cutting forces, but it does nothing about chip clearance.”

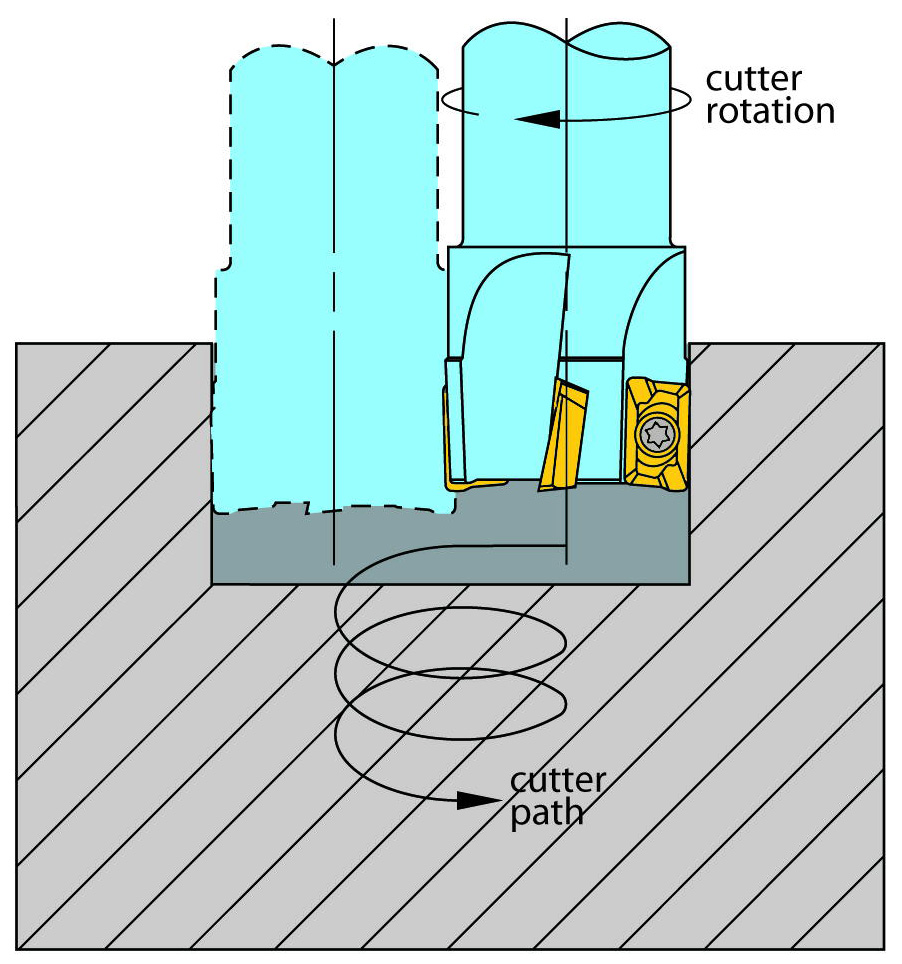

Unlike orbital milling, corkscrew milling involves simultaneously feeding on all three axes: advance on the Z-axis while simultaneously interpolating on the X- and Y-axes to enlarge the hole. This requires a machine with interpolating capability. By contrast, orbital milling uses a step-and-orbit cycle.

Since there is only a small contact area between the tool and the workpiece at any instant, cutting forces with corkscrew milling are much lower than in twist drilling. Completely absent is the friction between drill flutes, chips and sidewall of the hole.

R&R estimates that retooling the corkscrew milling operation will save approximately $49,000 a year. Not a week goes by that this process isn’t running on some job. Accordingly, the High Feed Mini has a permanent place in the Fadal tool magazine on the shop floor. “We’ve stayed pretty close to Ingersoll’s recommended machine settings,” adds Barnes. “We practice continuous improvement, but as a small shop we have to rely on the experience of trusted vendors. We’re just too small and too busy to experiment a lot on our own.”

R&R Machine, 1221 Cochran Avenue, Talladega, AL 35160-3650, 256-375-9845.

Deering Machine, 194 Asa Cash Road, Bremen, GA 30110, 770-574-9950.

Ingersoll Cutting Tools, 845 S. Lyford Road, Rockford, IL 61108-2749, 815-387-6600, Fax: 815-387-6968, info@ingersoll-imc.com, www.ingersoll-imc.com.