Choosing the Right Deburring Method

An overview of FLADDER® deburring system from Fladder — Hansen & Hundebol Inc. and its capabilities.

Posted: April 27, 2013

An overview of FLADDER® deburring system from Fladder — Hansen & Hundebol Inc. and its capabilities.

The FLADDER® deburring system employs an entirely new method based on a principle which is fundamentally different from those of traditional deburring methods.

The abrasive tool in the FLADDER® deburring system from Fladder — Hansen & Hundebol Inc. (Atlanta, GA) is a flexible tool with a number of slats or strips of abrasive material which rub tightly against the part, closely following its contours. When it comes to choosing the right method there are a number of choices, depending on the desired quality — and of course the allowed budget!

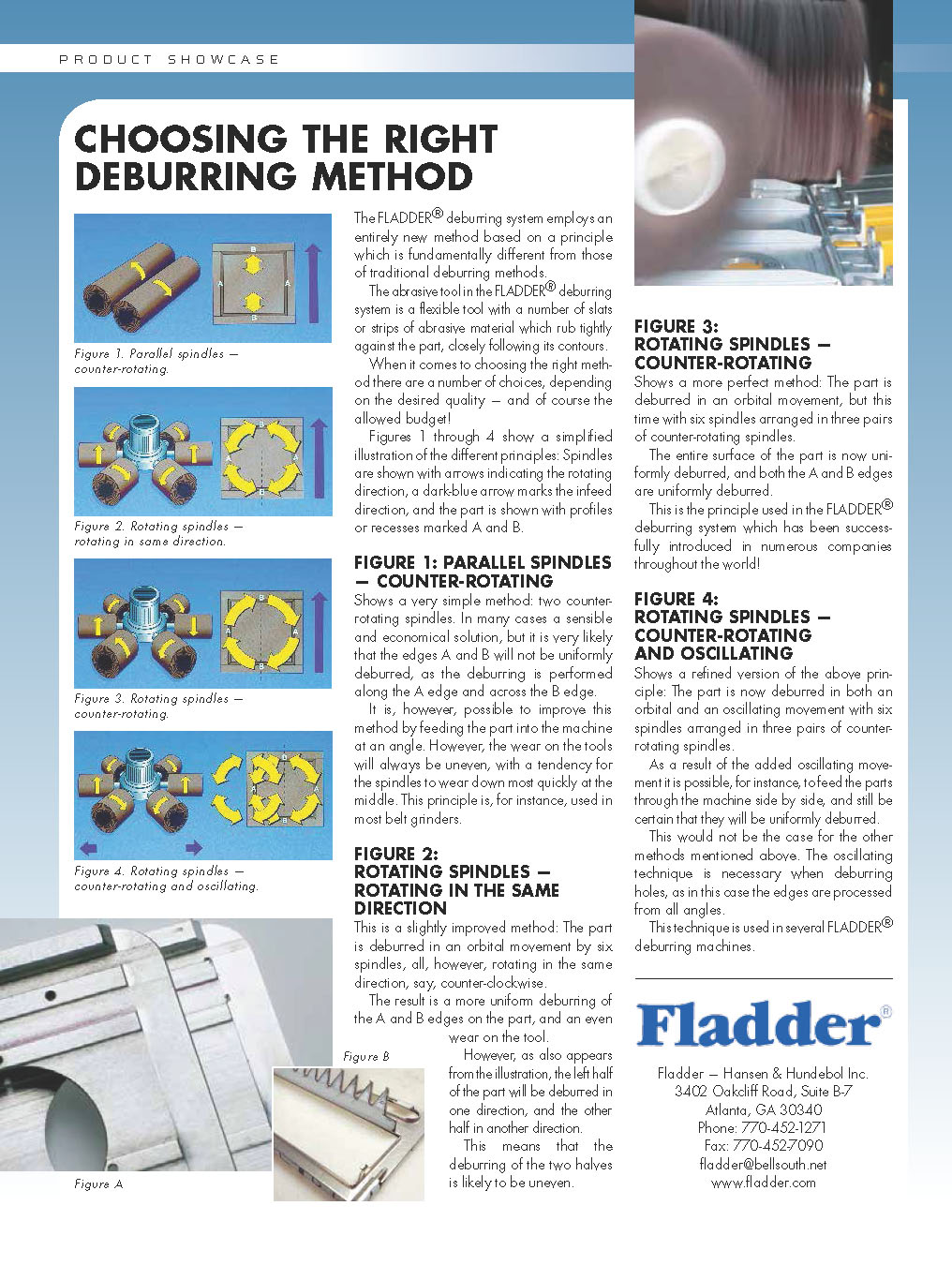

Figures 1 through 4 (enlarge illustration on the right) show a simplified illustration of the different principles: Spindles are shown with arrows indicating the rotating direction, a dark-blue arrow marks the infeed direction, and the part is shown with profiles or recesses marked A and B.

FIGURE 1: PARALLEL SPINDLES — COUNTER-ROTATING

Shows a very simple method: two counter-rotating spindles. In many cases a sensible and economical solution, but it is very likely that the edges A and B will not be uniformly deburred, as the deburring is performed along the A edge and across the B edge.

It is, however, possible to improve this method by feeding the part into the machine at an angle. However, the wear on the tools will always be uneven, with a tendency for the spindles to wear down most quickly at the middle. This principle is, for instance, used in most belt grinders.

FIGURE 2: ROTATING SPINDLES — ROTATING IN THE SAME DIRECTION

This is a slightly improved method: The part is deburred in an orbital movement by six spindles, all, however, rotating in the same direction, say, counter-clockwise. The result is a more uniform deburring of the A and B edges on the part, and an even wear on the tool.

Figure B however, as also appears from the illustration, the left half of the part will be deburred in one direction, and the other half in another direction. This means that the deburring of the two halves Figure A is likely to be uneven.

FIGURE 3: ROTATING SPINDLES — COUNTER-ROTATING

Shows a more perfect method: The part is deburred in an orbital movement, but this time with six spindles arranged in three pairs of counter-rotating spindles.

The entire surface of the part is now uniformly deburred, and both the A and B edges are uniformly deburred. This is the principle used in the FLADDER® deburring system which has been successfully introduced in numerous companies throughout the world!

FIGURE 4: ROTATING SPINDLES — COUNTER-ROTATING AND OSCILLATING

Shows a refined version of the above principle: The part is now deburred in both an orbital and an oscillating movement with six spindles arranged in three pairs of counter-rotating spindles. As a result of the added oscillating movement it is possible, for instance, to feed the parts through the machine side by side, and still be certain that they will be uniformly deburred.

This would not be the case for the other methods mentioned above. The oscillating technique is necessary when deburring holes, as in this case the edges are processed from all angles. This technique is used in several FLADDER® deburring machines.

Fladder — Hansen & Hundebol Inc.

3402 Oakcliff Road, Suite B-7

Atlanta, GA 30340

Phone: 770-452-1271

Fax: 770-452-7090

fladder@bellsouth.net

www.fladder.com