Machining Heat: Foe or Friend?

These two technical studies from Ingersoll Cutting Tools examine how different machine shops are using next generation machining geometry to manage heat at the cutting edge.

Posted: August 12, 2013

Usually machining heat impairs milling, but sometimes it can help. On the one hand, too much heat can weaken the cutting edge or distort the workpiece, and even squander up time for indexing because the tool is too hot to handle. On the other, a little heat imparted to the cutting zone on hardened steels can facilitate things.

“The trick is to manage the heat, to direct the bulk of it into the chip rather than the tool or workpiece, and to expel that hot chip fast,” says Konrad Forman, the North American milling product manager for Ingersoll Cutting Tools (Rockford, IL). “If you see the tool or workpiece glowing orange, there’s always a better way, and the remedy usually involves a more efficient geometry at the cutting edge.”

Forman recalls these recent examples:

- Slot roughing hardened steel extrusion dies: Solid carbide endmills were actually glowing orange at a Midwest mold shop, even at vastly reduced removal rates. Using up-to-date indexable high feed mills matched to high-feed machine settings, the glow is gone, the removal rate has tripled and one set of edges lasts five times longer.

- Finish-milling aluminum engine castings requiring extreme flatness and fine finish: At Continental Motors, Inc. (Mobile, AL), machining heat with an older cartridge type PCD facemill was distorting aluminum engine castings during the finishing operation.This raised rework costs and triggered stoppages necessary to re-clamp the parts and relieve the heat stresses. With the switch to a breakthrough indexable cartridge type PCD cutter running at 10,000 rpm, heat problems went away and flatness and finish improved – at twice the previous material removal rate (MRR).

- Rough milling hardened big alloy steel castings: Terex Corporation (Westport, CT) doubled throughput of trannie boxes for off-road equipment, improved edge life and eliminated downtime caused by over-long indexing delays waiting for the tool to cool down enough to be handled.Their solution: switch from radial to tangential milling and make machining heat an asset. They run their tangential facemill at rates just high enough to momentarily soften metal in the cutting zone.

INSERT FEATURES FOR COOLER RUNNING

Modern indexable inserts mitigate machining heat several ways, according to Forman. Here are the main improvements:

- Geometry – Positive rakes and free cutting insert geometries reduce cutting forces and enable higher feeds without overheating the cutting zones.Top-face geometries expel hot chips before they can transfer heat to the tool as well as reducing the contact area between chip and tool.

- Substrates – Proprietary advances provide better combinations of heat resistance, wear resistance, toughness and application versatility.

- Coatings – Surface coatings are slipperier to reduce friction and stress raisers. Improved thermal coatings keep the substrate cooler.

- Coolant Delivery – Through-the-tool plumbing delivers coolant right to the cutting zone for more effective cooling and chip flushing.

DIMMING THE GLOW IN MOLD SLOTTING

In the mold shop plagued by those glowing orange endmills, the previous standard practice for the slots was a “plunge and walk” toolpath using ½ in solid carbide end mills running at a gentle 30 ipm to 50 ipm, 250 sfm at a 0.050 in depth of cut (DOC).

Moldmakers also tried to work around the problem by pre-drilling the plunge point and stepping down in only 0.050 in increments. Still the cutters quickly snapped or overheated, often just 15-20 seconds into the cut.

Over past years, manufacturing engineers there had tried several mainstream indexable mills and discarded them for lack of any real improvement. The difference this time was a process change to high-feed milling, which involves very fast feeds at lower depths, enabled by an indexable Power Feed + mill built specifically for that process. Typical parameters now are 180 ipm, 450 sfm, 0.025 in DOC.

This change reduces average cycle time per slot to two hours from five and leaves the slot nearer to net shape, which saves finishing time. And because the operation runs cooler, a single set of indexable edges lasts through the entire cut. Even in hardened stainless steel or hi-hard P 20, Rc 38-45, red-hot endmills are a thing of the past.

COOLER RUNNING JUST THE BEGINNING

By retooling with the cooler running TEDIMILL face mill on their engine castings, Continental Motors got two additional dividends.

First, they no longer need to stop and re-clamp the larger castings in mid cut to relieve machining heat stresses. Second, they now rough and finish with the same facemill, halving cycle time and eliminating a parts transfer to a second machine.

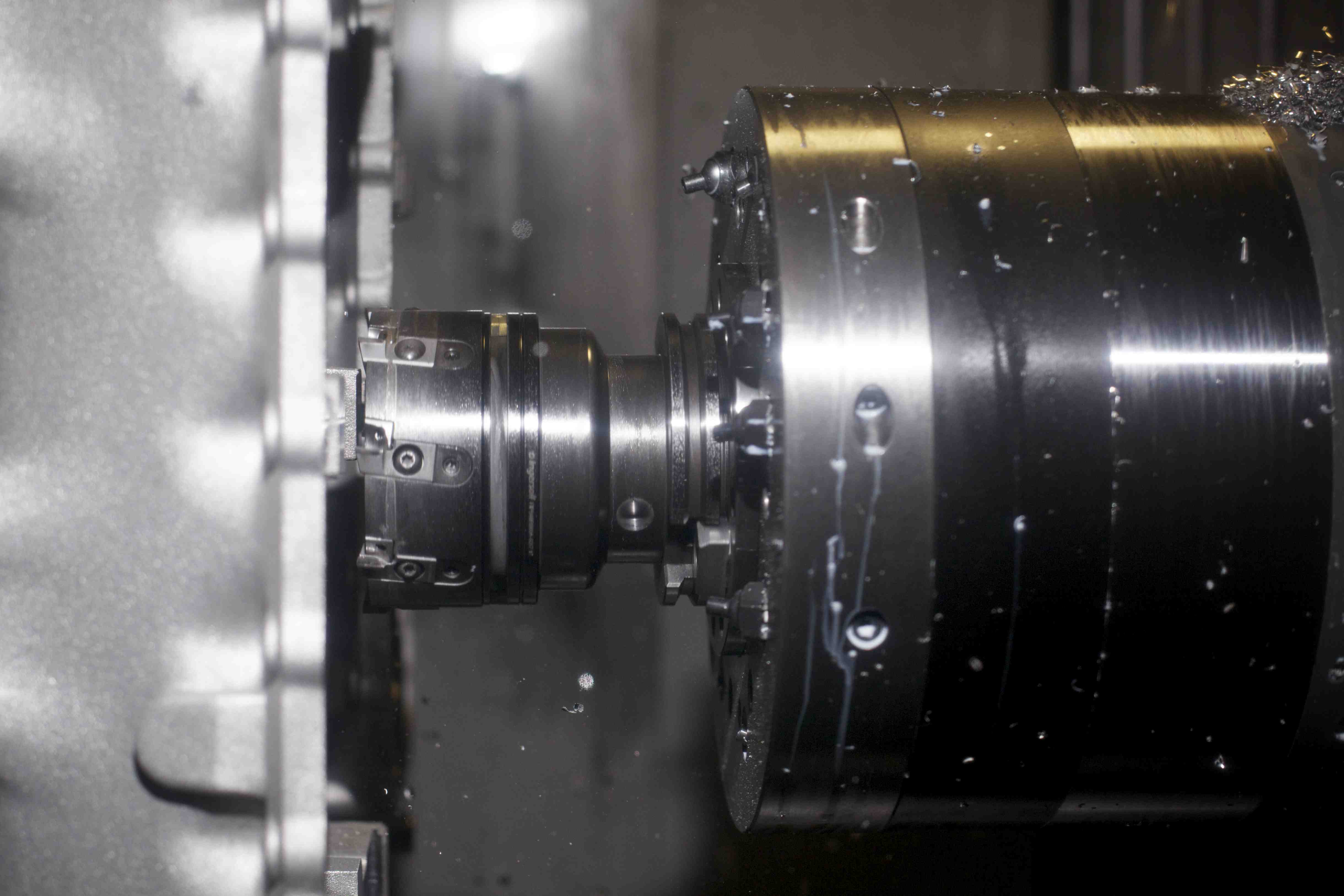

Previously Continental roughed the castings with an indexable carbide insert (ICI) under flood coolant. “With through-the-tool coolant delivery in the new cutter, we’re getting fast chatter-free milling at spindle speeds and feed rates that defy belief – without any overheating,” says manufacturing engineer Mike Brown. He runs at 10,000 rpm during the day shift and ramps back to 9000 rpm during “lights out.”

TEDIMILL face mills are the only cutting tool offered as standard from Ingersoll’s sister company in the IMC group, Italian technical Diamond Company. After convincing successes milling automotive engine blocks throughout the industrialized world, the TEDIMILL line was moved into the U.S. market in 2011, first as a special and now as a standard.

Unlike all other indexable PCD facemills, the TEDIMILL offers all the most-wanted features in one tool: absolutely rigid cartridge seating, positive rake presentation, through-the-tool coolant delivery direct to the cutting zone, 20,000 rpm “out of the box” certification, chamfered insert corners to reduce lateral forces, and simple cartridge adjustment within 2 microns.

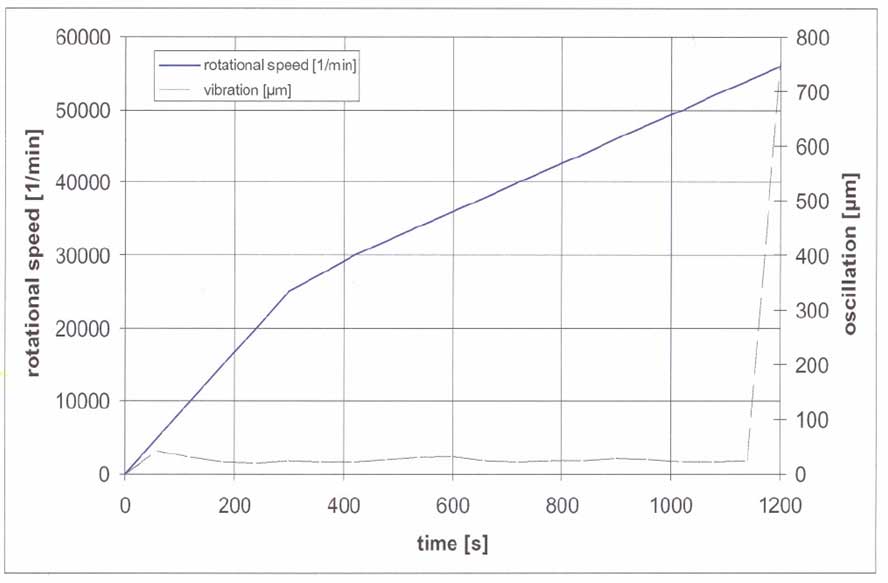

In independent trials on the fastest spindle in the world, a fine-tuned TEDIMILL has run at 50,000 rpm.

REDUCING – AND CHANNELING – THE HEAT

The big driver for retooling at Terex was to increase plant capacity while averting new capital expenditures. The workpieces are big hardened alloy steel transmission boxes for construction equipment. Engineers there quickly identified flat rough milling operations on those parts as the “opportunity operation” to debottleneck.

Not only did the roughing operation overheat the tools, leading to sudden, premature edge breakdown. At indexing time, the tools were literally too hot to handle for nearly half an hour. The overheated tools, conventional radial ICI mills, also vaporized the oil mist coolant, often creating a cloud so dense that it kept personnel away.

“We’d have been happy to just be able to get to a broken tool, change it quickly and resume production sooner,” says Jim Rice, Terex operations manager. “Now, moreover, we have also cut cycle time in half, extended edge life fivefold and eliminated all sudden edge failures – running dry. We gained the added capacity we were looking for without opening our checkbook, plus a cleaner workstation.”

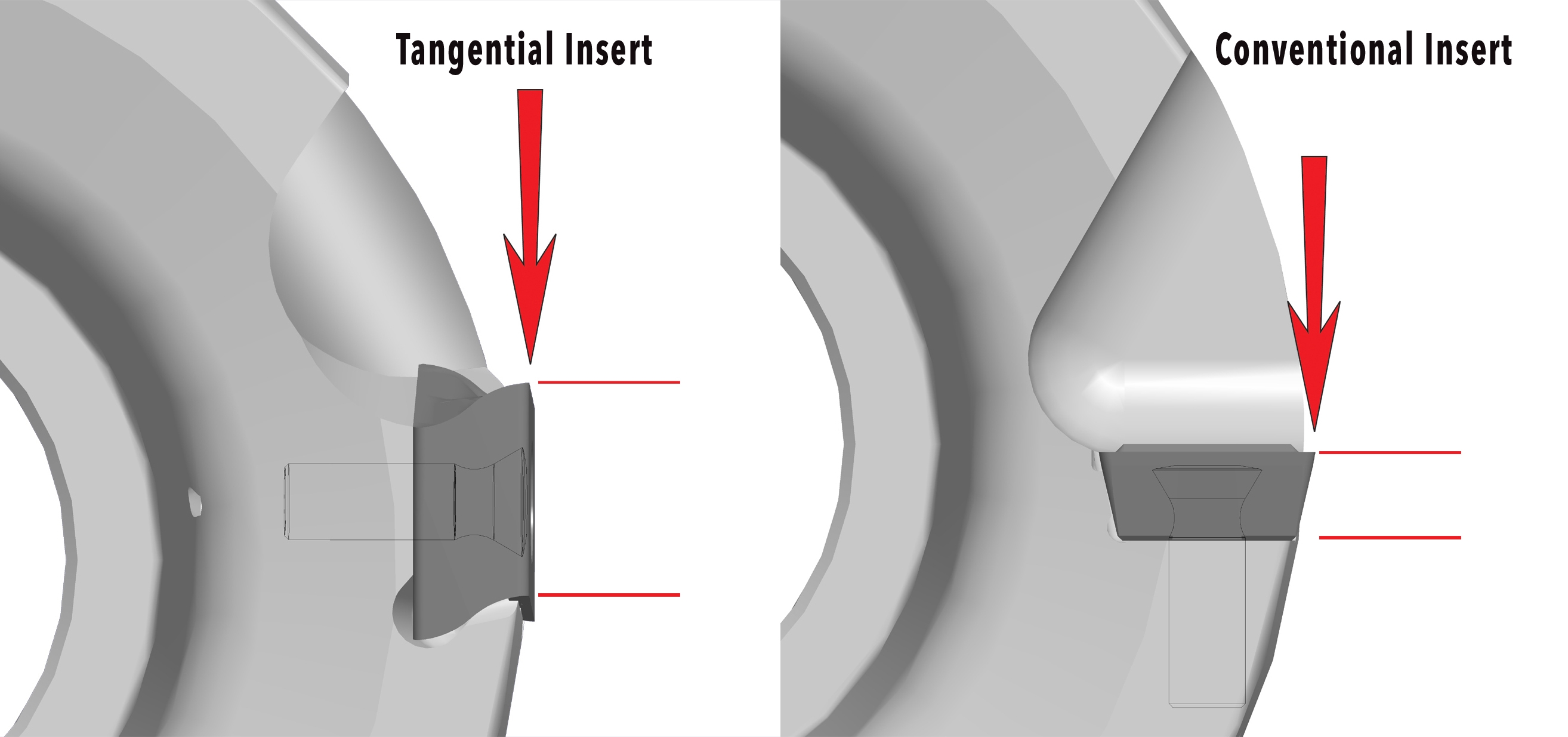

What made the difference was the switch from radial to tangential milling, using an S MAX facemill, and then setting a material removal rate just high enough to heat the cutting zone slightly and soften the Rc32 stock.

In tangential milling, the inserts lie flat in the cutter’s pitch circle, not upright, creating a fundamentally stronger cutting geometry. Moreover, the positive rake angle and top-face features combine to both reduce cutting forces and direct machining heat into the ejected chip instead of the cutter.

“Reduce the machining heat, put it where you want it, and you come out money ahead every time,” concludes Mr. Forman.

Ingersoll Cutting Tools, 845 S. Lyford Road, Rockford, IL 61108-2749, 815-387-6600, Fax: 815-387-6968, info@ingersoll-imc.com, www.ingersoll-imc.com.

Continental Motors, Inc., 2039 Broad Street Mobile, AL 36615, 251-438-3411, www.continentalmotors.aero.

Terex Corporation, 200 Nyala Farm Road, Westport, CT 06880, 203-222 -7170, Fax: 203-222-7976, info@terex.com, www.terex.com.