Factors for Selecting the Right Stick Electrode

The stick electrode used in an application can have a significant impact on the quality of the final weld. Consideration of these factors is a good start to overcoming the challenge of selecting the correct stick electrode for a particular job.

Posted: September 24, 2013

While many companies have turned to wire welding processes to speed production and simplify training, stick welding still has a prominent place in industry applications — structural steel erection, pipeline construction, small fabrication jobs and maintenance/repair operations, to name a few.

In some cases, the stick electrodes used in the process are more able to meet the mechanical and chemical properties of the materials used in a given application. In other situations, it’s a matter of welding procedure specifications or the skill set of the available workforce. Too, since the stick welding process is highly portable (it doesn’t require an external shielding gas), it’s a good choice when mobility is a factor.

At the heart of stick welding, just like any other welding process, is the filler metal. Stick electrodes are available in a variety of alloys, hydrogen designations and diameters. Knowing the proper product for the application is key to gaining consistent weld quality and avoiding downtime for rework.

ASSESS THE BASE MATERIAL

The goal in selecting a stick electrode is to determine which one provides the best properties for the given application. The deposited weld metal should equal the properties of the base material as close as possible and have approximately the same composition and physical properties. To that end, it is critical to identify the base material strength properties and chemical composition before making the selection.

Bruce Morrett discusses the filler metals, including tubular wires, solid wires and stick electrodes, featured at the FABTECH 2011 show in Chicago. He also shares news on MAXAL aluminum wires.

In some cases, particularly maintenance/repair operations, the base material may not be readily known. Consider the following factors to help with the identification. First, determine whether the base material is magnetic, which indicates that it is a carbon or alloyed steel. If the base metal is not magnetic, the material is likely manganese steel, 300 series austenitic stainless steel or a non-ferrous alloy such as aluminum, brass, copper or titanium.

Next, if the base material is unknown, it can be helpful to use a grinder “touch test” to identify it. More flare in the sparks when the grinder touches the material indicates a higher carbon content, such as associated with A36 grade steel.

Finally, determine whether a chisel “bites” into the base metal or bounces off of it. A chisel will bite into a softer metal, such as mild steel or aluminum, and bounce off of harder metals, such as high carbon steel, chrome-moly or cast iron. Combined, these tests can provide a good indication of the base material at hand and help simplify the stick electrode selection.

MATCHING TENSILE STRENGTHS

Preventing cracking or other weld discontinuities is critical in any welding process and can be done by appropriately matching the base material and filler metal tensile strengths. A stick electrode’s tensile strength can be identified by referring to the first two digits of the American Welding Society (AWS) classification printed on the side.

For example, the number “60” on an AWS E6011 electrode indicates that the filler metal produces a weld bead with a minimum tensile strength of 60,000 psi and, as a result, would work well with a steel of similar tensile strength.

WELDING CURRENT

Certain stick electrodes can be used with only AC or DC power sources, while other electrodes are compatible with both. It is important to match the stick electrode to the available power source in order to gain the best results.

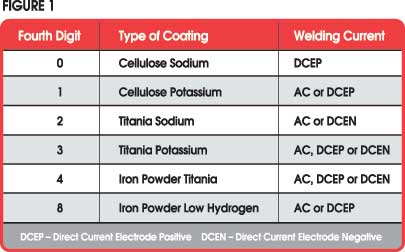

To determine the correct current type for a particular stick electrode, refer to the fourth digit of the AWS classification, which represents the type of coating that is compatible with a given welding current.

For example, a stick electrode ending in a ‘0’ has a high cellulose sodium coating, making it compatible for DCEP (electrode positive) welding, whereas one that ends in ‘8’ has a low hydrogen potassium and iron powder coating and can be used for DCEP, DCEN, (electrode negative), and AC welding. See Figure 1 as an additional reference on stick electrode coatings and welding currents.

The type of current will also influence the penetration profile of the resulting weld. For example, a DCEP-compatible product, such as an AWS E6010 stick electrode delivers deep penetration and produces an extremely tight arc. It also has the ability to “dig” through rust, oil, paint and dirt.

Conversely, a DCEN-compatible product, such as an AW E6012 stick electrode, provides mild penetration and works well when bridging two joints or welding at higher speeds. It is also a good choice for high current fillet welds being completed in the horizontal position. An AC-compatible stick electrode, such as an AWS E6013, produces a soft arc with medium penetration and can be used to weld clean, new sheet metal.

BASE METAL THICKNESS AND CONDITION

The thickness or thinness of a base material will also factor into the stick electrode selection process. A stick electrode with maximum ductility and low hydrogen is an especially good choice to prevent cracking on thicker base materials.

For instance, stick electrodes with AWS classification numbers ending in 15, 16 or 18 provide excellent properties that are capable of accommodating for residual stress that can accumulate in welds on thick sections.

For thin materials, it is important to select a stick electrode that produces a soft arc. An AWS E6013 is a good choice to prevent burn-through or distortion. Smaller diameter stick electrodes are also a good option for welding thinner materials, as they provide shallow penetration to help prevent similar issues.

In addition to selecting a stick electrode based on material thickness or thinness, it’s important to assess the joint design and fit-up. For example, when working on a joint with tight fit-up or one that is not beveled, stick electrodes that provide good penetration — an AWS E6010 or E6011 product — are the best choice to ensure complete fusion.

And while it’s always recommended to remove mill scale, rust, moisture, paint and grease from the base material before welding — clean base materials help prevent porosity and increase travel speeds — if that is not possible, arcs created by AWS E6010 or E6011 stick electrodes also have the ability to cut through such contaminants.

A stick electrode, such as an AWS E6012 is good for welding materials with wide root openings, as this product creates a concave weld face suitable for bridging gaps and making groove welds.

THE POSITION OF THE WELD

Ideally, all welds would be able to be completed in the flat welding position; it is the easiest way to gain control over the weld pool and achieve the best weld quality. Since that is not a reality, however, it is critical to choose a stick electrode that can accommodate for the position of the weld.

To determine what position(s) a particular electrode is qualified for, refer to the third digit in AWS classification. Those stick electrodes with a ‘1’ can be used for welding in flat, horizontal, vertical and overhead positions. Those with a ‘2’ can be used for flat and horizontal welding only.

KNOW THE SPECIFICATIONS AND SERVICE CONDITIONS

Before making the stick electrode selection, make sure to assess the conditions that the welded part will encounter throughout its service. If it will be used in high heat or low temperature environments, or subjected to repetitive shock loading, a low hydrogen stick electrode with higher ductility can help reduce the chance of weld cracking. Also, be certain to check for welding specifications when working on critical applications such as pressure vessel or boiler fabrication.

In most cases, these welding specifications will require the use of specific types of stick electrodes that can withstand elevated temperatures for longer periods of time and/or to prevent corrosion resistance.

FINAL THOUGHTS ON STICK ELECTRODES

The stick electrode used in an application can have a significant impact on the quality of the final weld. The above factors are a good start in overcoming the challenges of selecting the correct stick electrode for a particular application.

However, given the wide range of available stick electrodes, several solutions may exist for one application. For additional assistance with the stick electrode selection process, consult a trusted welding supply distributor or filler metal manufacturer.