Rotating-Head Bending Replaces Hydraulic Benders

This novel tube bender has boosted productivity by an eye-opening 500 percent for this Midwest tubular part fabricator.

Posted: September 12, 2013

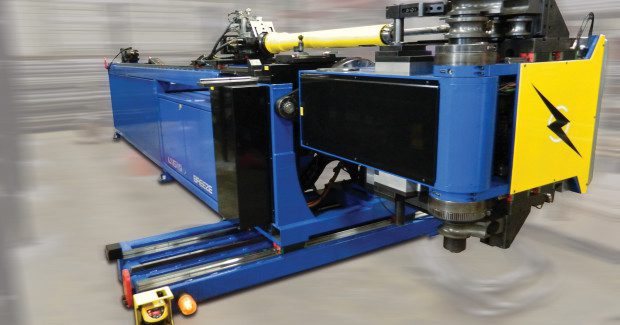

The Unison machine installed at Sharpe Products (New Berlin, WI) uses a rotating head action that allows it to make left-hand and right-hand bends in one continuous cycle, doing the work of two of the shop’s previous hydraulic tube benders while also speeding throughput by up to five times. This performance is enabling the fabricator to reduce their lead times significantly on a wide range of complex multiple-bend jobs, as well as on parts requiring bends of widely different radii.

The machine was supplied by Unison’s North American partner, Horn Machine Tools (Madera, CA). It increases the number of Unison machines that Sharpe operates to three, and follows the firm’s long-term strategy to gain control commonality across its tube fabrication operation by progressively replacing old machines with Unison’s all-electric tube bending technology. This approach has major time and cost-saving advantages. Operators only need to be trained to use a single type of machine, and can then be deployed wherever they are most needed within the company. Sharpe is choosing to standardize on Unison tube benders because they have proved to provide the performance that the company needs to maintain its competitive edge, and because it has found its support service to be second to none.

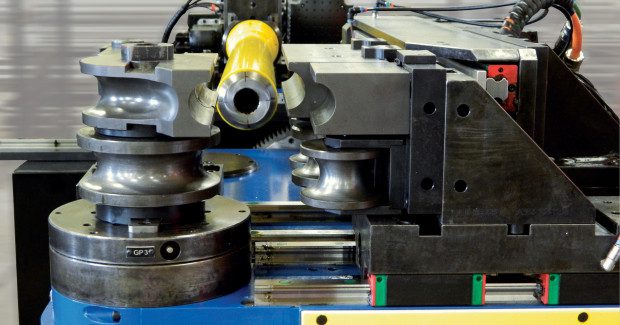

Sharpe’s latest machine is a Unison 2 in (50 mm) Breeze-Revolution tube bender that provides both left-hand and right-hand bending. The machine has two multi-stack tool heads mounted on opposite sides of a rotating frame. After bending using one or more tools on one head, the head retracts and a combination of transverse and rotational movement then positions the other head for subsequent bending operations. Changeovers between left-hand and right-hand bending heads can be repeated as many times as needed, allowing complex shapes to be fabricated completely automatically without removing the tube or involving any other machines.

“The flexibility of this machine has to be seen to be believed,” says Sharpe’s president, Paul Krickeberg. “A lot of the parts we produce, such as exercise machine frames and architectural handrails, are manufactured from standard 1.5 in to 2 in tubing and require a mix of small and large radius right- and left-hand bends. Until now, we have used two hydraulic benders – one for right-hand bends, the other for left-hand bends – which could involve up to three separate machine cycles and easily take five or more minutes. The Unison machine creates all the bends that are needed in a single cycle, and typically in less than a minute.”

“What’s more,” Krickeberg adds, “by replacing the two hydraulic benders with a single compact machine that can handle right or left bending we have gained valuable production floor space, which is always at a premium. The configuration that we ordered is capable of roll forming as well as rotary draw bending, so we can create large radius bends or tight radius bends down to 1D without changing machines.”

All Unison tube benders use precision software-controlled servomotors for movement control and feature fully automatic set-up, enabling them to be configured for new batches very quickly. They can typically be set up in about a third of the time of a hydraulic bender and provide extremely tight control of the bending process, enabling parts to be manufactured right first time, or immediately after producing a single trial part.

The firm has extensive experience of Unison all-electric tube benders – it has used the company’s 3 in and 5 in (76 mm and 130 mm) machines for many of its operations for a number of years – and is extremely pleased with their performance and reliability, as well as the level of support provided by Unison. The machines are also popular with the workshop staff, who find them easy to set up and operate.

All three tube benders are connected to an automation network. The first trial tube of every batch undergoes detailed examination by Sharpe’s quality assurance department, using a computer-based tube inspection machine. The machine compares measurements obtained from the trial part with those of the intended design, and sends any necessary correction data to the appropriate bending machine. Sharpe also intends using the network for downloading data from its CAD systems direct to the bending machines, to further speed design-to-manufacture.

The 5 in Unison tube bender is equipped with Unison’s unique laser-controlled springback measurement and correction system, which was fitted retrospectively in 2012. This ensures bending precision by automatically compensating for the natural tendency of metal pipes and tubes to spring back slightly after being bent. According to Krickeberg, “Customers are increasingly demanding very accurate parts and very fast delivery. Unison’s springback correction system provides us with a powerful competitive advantage, by enabling us to bend to an accuracy of one tenth of a degree. We are about to ask Unison to retrofit this system to our 3 in bender.”

Sharpe Products started up in 1990 as an architectural tube and pipe bending metalwork specialist, but its business has evolved and today the company’s output is split almost equally between the architectural sector, tube and pipe parts for OEMs, and custom-fabricated assemblies. The company has 13 bending machines in total, with all-electric bending machines spanning a size range from 32 mm to 130 mm. Sharpe handles even larger tube and pipe sizes using hydraulic machinery resources.

Horn Machine Tools, 40473 Brickyard Drive, Madera, CA 93638, 559-431-4131, sales@hornmachinetools.com, www.hornmachinetools.com.

Sharpe Products, 2550 S. 170th St., New Berlin, WI 53151, 262-754-0369, sales@sharpeproducts.com, www.sharpeproducts.com.