Synchronized Tandem MIG® Process Revealed

This examination of Tandem MIG shows how it extends the welding productivity range beyond that possible with conventional single-wire processes.

Posted: September 30, 2013

Since the introduction of Tandem MIG in the early 1990s, the estimated installed base of dual wire MIG (GMAW) systems has grown to over 1,000 units worldwide. The majority of the systems installed have replaced single-wire processes that had been pushed to the extreme high end of the useable operating range in an attempt to improve productivity and lower cost by depositing as much metal as possible in the shortest time frame. Tandem MIG extends the welding productivity range beyond that possible with conventional single-wire processes.

PROCESS DESCRIPTION

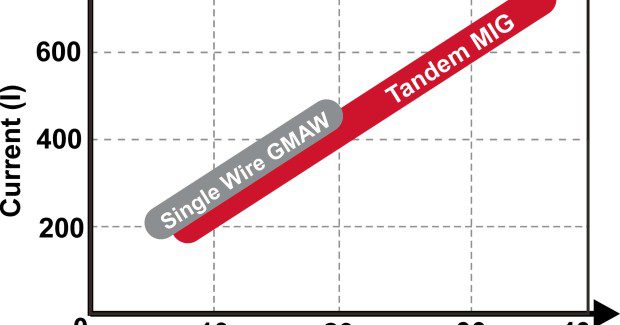

The maximum deposition rate in a traditional single-wire GMAW (MIG) process is limited by the saturation current (I) for any specific wire diameter. To overcome this limitation, tandem MIG combines two separate MIG welds into a single application. The outcome is a process capable of nearly double the deposition rate of single wire MIG (see Figure 1).

Synchronized Tandem MIG® increases stability, reduces spatter and improves bead appearance compared to a standard Tandem MIG process. This improved process utilizes a pulse waveform and synergic precision controls allowing customization of both arcs to meet specific application needs. UltimArc™ controls fine tune the ramp, peak, background and tailout for each arc. The resulting improved process provides exceptional deposition rates and fast travel speeds.

Tandem MIG is a dual wire, high productivity GMAW process designed for flexible robotic or fixed hard automation welding applications. The process utilizes high-speed inverter Waveform Control Technology™ to coordinate two separately generated GMAW welding arcs in unison for exceptional process flexibility. Independent control of both the lead and trail wire parameters of the tandem process allows procedure optimization for bead wetting, bead profile and penetration. Tandem MIG has proven to frequently double the production of single GMAW processes.

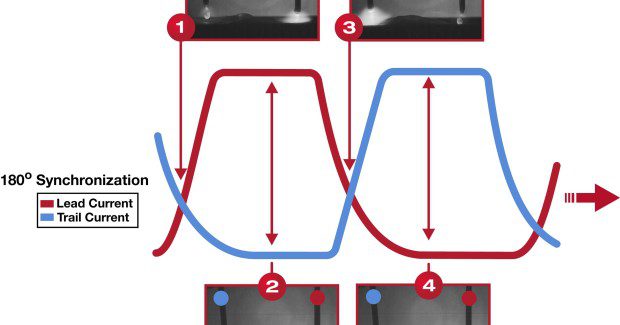

A visual explanation of how the Tandem MIG waveform operates is shown in Figure 2. Step 1 begins with the Lead Arc – Ramp, where a rapid current increase begins the process of creating a single molten droplet. It is followed by the Trail Arc – Tailout, where a reduction in current (Tailout) relaxes the plasma force as the droplet separates and approaches the puddle (see Figure 2-1).

Step 2 involves the Lead Arc – Peak, where a peak current creates a molten droplet providing sufficient pinch force to begin separation, and the Trail Arc – Background, where the trail arc reaches a minimum current level (background current) and maintains the arc without additional metal melt-off (see Figure 2-2).

Step 3 includes the Lead Arc – Tailout, a reduction in current (Tailout) relaxes the plasma force as the droplet separates and approaches the puddle. And the Trail Arc – Ramp, a rapid current increase begins the process of creating a single molten droplet (see Figure 2-3).

Step 4 is the Lead Arc – Background, where the lead arc reaches a minimum current (background current) and maintains the arc without additional metal melt-off. Then the Trail Arc – Peak, where a peak current creates a molten droplet providing sufficient pinch force to begin separation (see Figure 2-4).

PROCESS OVERVIEW

Synchronized Tandem MIG® is generally broken up into two main application categories, High Speed and High Deposition. The chart in Figure 3 shows general guidelines on how the two different categories are defined. Understanding the specific Tandem MIG application is important so process variables can be set correctly.

Production cells welding large components must be cost justified in a different way based more on welding time and not part count. The heavy equipment industry, which was the first to embrace the Tandem MIG process, typically utilizes large robotic work cells that include expensive positioners to handle the large and heavy weldments that often take two or more hours to weld.

Most weldments must be placed in the flat or horizontal position. This requires the use of large positioners and makes the use of multiple robots per cell difficult. Tandem MIG has repeatedly been used to replace single-wire robotic systems welding that were averaging deposit rates in the range of 15-20 lb/hr. Tandem MIG operates in the 28-34 lb/hr range.

The increased weld metal deposit rate has been used to justify the cost of purchasing new more technically sophisticated workstations. Tandem MIG continues to benefit a number of industries, from companies welding thin sheet metal automotive components to companies performing multi-pass welding of large earth moving equipment and offshore drilling rigs.

Kent Johns, an application engineer for Lincoln Electric, also contributed to this article.