Your Mother Doesn’t Work Here: Why Housekeeping Matters

The dangers of poor housekeeping are real. It saps productivity, morale and operating efficiency, yet goes largely ignored. When every competitive dollar counts, it’s puzzling that more shops don’t make a concerted effort to address a problem that is so easy to fix.

Posted: September 20, 2013

Perhaps the easiest — and most ignored — way to make your workplace safer is by improving your housekeeping. According to the National Safety Council (Itasca, IL), “Falls are one of the leading causes of unintentional injuries in the United States, accounting for approximately 8.9 million visits to the emergency department annually (NSC Injury Facts 2011).”

While not all slips, trips and falls are caused by housekeeping issues, a simple campaign to ensure a place for everything and that everything is in it’s place goes a long way toward improving not just working conditions, but safety of the workplace itself.

Housekeeping was traditionally a panicked response to a surprise visit by a customer or an audit. Workers were sent scurrying to “pick up the newspapers” as company stopped by unexpectedly. But housekeeping ought to be more than the frenzied reaction to an unplanned visit. Housekeeping is an important defense against trip hazards, accidental exposure to hazardous materials, fire hazards and a host of other nasty scenarios. Housekeeping is more than just tidying up; a robust housekeeping campaign can improve your operating efficiency in many ways beyond worker safety.

MATERIALS MANAGEMENT

Housekeeping discipline is a subset of operational discipline. A strong commitment to housekeeping can address inventory management and control (clearing stock out of the aisles and removing and disposing of scrap and obsolete equipment and stock, for example.)

SALES

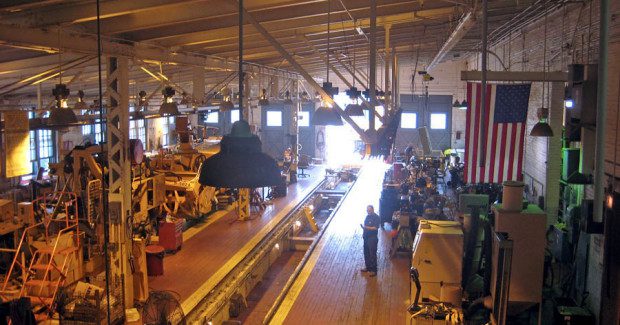

When you seriously attack housekeeping, you will find that your workplace will look less like an episode of hoarders and more like a world-class operation.

I know of a manufacturer that does a fair amount of work for the U.S. government. The G-men were generally pleased with the quality, cost, and delivery of the products the shop built, but were consistently disappointed by the physical condition of the plant: the facility was cramped and crowded with trash and stock strewn around the production area; it simply didn’t look very professional.

Once the company undertook a safety campaign that included a 5S program (a Japanese concept of workplace organization that places a high priority on housekeeping), the government representatives immediately took notice. The feds who came in on surprise inspections were struck by the cleanliness of the plant and actually increased their orders. While the increase in business was certainly the result of multiple factors, a clean and orderly workplace made the decision to source the work to the manufacturer easier and more defensible.

ENGAGEMENT

According to best selling author and employee engagement expert Dr. Paul Marciano, employee engagement is about respect; workers who feel respected by their employers are far more likely to be engaged than those who feel disrespected.

Good housekeeping is a key indicator of respect; you can easily gauge the level of respect employers have for their workers — and how workers about themselves — simply by looking at their housekeeping practices. Good housekeeping isn’t the result of panic-cleaning, spring cleaning, or even cleaning up once a day. Good housekeeping is the result of a clearly cast expectation of respect, i.e., the product of an expectation of respect for oneself, one’s colleagues, and one’s work place.

Housekeeping is the manifestation of pride in your organization. A clean and well-organized workplace is the cornerstone of a robust safety management program that promotes worker safety, respect, dignity, and morale.

MAINTENANCE

One of the biggest offenders of poor housekeeping is the maintenance department. Often, removing obsolete equipment or fixtures, cleaning dross or offal, or just plain picking up after oneself is seemingly impossible for many maintenance workers. The clutter caused by poor housekeeping practices on the part of maintenance is truly embarrassing in some organizations.

Why is it so difficult for maintenance to pick up after itself?

One reason is the permitting process. Even organizations that are otherwise good at housekeeping often struggle with seeing the work orders and permits through to completion. Final project clean up is often over looked and — because it isn’t checked — is often seen as a non-priority.

In other cases it isn’t clear to whom a housekeeping duty falls. Who is responsible for keeping tools and equipment clean, in serviceable condition, and free from damage?

EFFICIENCY

It’s just plain easier to get things done in a neat and well-organized work area. In addition to preventing incidents, good housekeeping saves space, time, and money. Work is completed with minimal waste and be done with minimal effort.

WHAT ARE THE RISKS ASSOCIATED WITH POOR HOUSEKEEPING?

For organizations that are content to work in squalor, selling the need for good housekeeping can be tough. After all, what’s the risk of a little clutter? As it turns out, plenty.

Poor housekeeping can be directly linked to:

Slip, trips, and falls. According to OSHA “Slips, trips, and falls constitute the majority of general industry accidents. They cause 15 percent of all accidental deaths, and are second only to motor vehicles as a cause of fatalities.”

The situation is equally dire elsewhere, the Canadian Centre for Occupational Health and Safety reports that “in Canada, over 42,000 workers get injured annually due to fall accidents. This number represents about 17 percent of the “time-loss injuries” that were accepted by workers’ compensation boards or commissions across Canada”, and a European report in QBE Insurance Issues Forum reports that slips, trips and falls account for 37 percent of Health & Safety Executive reported accidents, and over 50 percent of public related injuries.

Increased fire hazards. Clutter, poorly labeled materials, flammable liquids left out or improperly stored, and other mess not only create a fire hazard they also can block emergency evacuation routes and impede rescue attempts.

Combustible dust. Combustible dust is a growing problem in industry and, in almost all combustible dust explosions, poor housekeeping has played an instrumental role in the disaster.

Exposure risks. Depending on your processes, poor housekeeping may lead to a higher probability of worker exposures to hazardous substances like asbestos, silica, or a host of other toxins.

Mobile Vehicle and Pedestrian Incidents. Poor housekeeping increases the need to handle materials and congests the flow of materials. Stock is misplaced, left to block pedestrian aisle ways and creates blind spots that can easily lead to serious workplace injuries.

Good housekeeping doesn’t just happen, but if you expect — no, demand — good housekeeping practices for your workplace , then you are on the road to success. But demanding good housekeeping isn’t enough. To achieve a sustainable housekeeping approach:

Allow workers time to clean up. This is a standard industrial engineering principle. You should budget enough time for workers to police and clean their work areas; it won’t get done unless you allot time for clean up.

Be consistent in your expectations. Cleanliness never sleeps and you can’t excuse lapses in housekeeping for any reason.

Provide supplies. Workers are far more likely to clean their work areas if they have appropriate and sufficient supplies to do so. Keep a cabinet full of cleaning supplies, brooms, mops, and fox tails that workers can use to clean their work areas.

Set an example. Only a hypocrite will expect workers to keep their work areas clean while working in an executive pig sty.

Even though the dangers of poor housekeeping are real and it saps productivity, morale, and operating efficiency the problem goes largely ignored. In a world where every dollar counts it’s puzzling that more organizations don’t make a more concerted effort to address a problem that is so easy to fix.