Automation for the Small Job Shop: Competitive Advantage

In part two of this three-part series, we walk through the mechanics of process control on the floor, the flexibility and lean manufacturing capabilities of automated welding, and how robots handle all sorts, sizes, shapes of parts – ideal solutions for the competitive job shop.

Posted: October 25, 2013

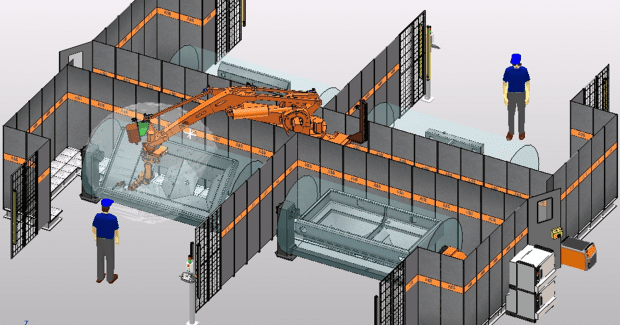

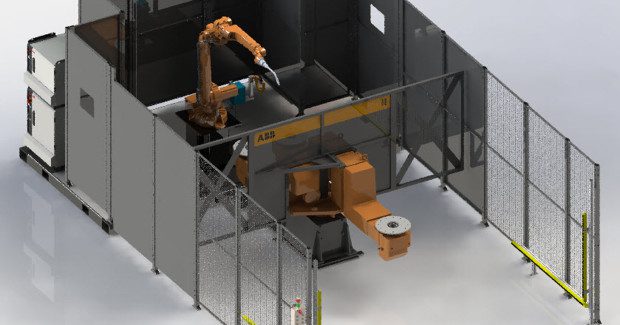

Visualize this: You’ve made the leap of faith and invested in the shiny new state of the art robotic welding cell, now residing prominently in your manufacturing facility (see Figure 1). The question you may have now is just exactly what will this machine do for my company. The answer is both broad and profound. Let’s deal with the obvious ones first.

CYCLE TIME AND CAPACITY

In general, you will be able to make the same product you produced before in a quarter of the time. The quality of the welded assembly will be second to none, produced to the same exemplary standards throughout your manufacturing week.

Your company’s manufacturing capacity for this type of work has likely quadrupled, allowing you to apply resources in other areas. You may have such a backlog that it simply means you can now meet your customers’ expectations. Perhaps you can allocate valuable skilled labor to take on more demanding projects within your factory, enhance you competitive edge by insourcing subcontract work that may not have been meeting the necessary time or quality requirements.

On a more subtle but equally important note, the new robotic capability can give you needed advantage to pursue new business and new markets. When seeking new business or expanding that with existing customers, robotic automation is going to place you at the top of the list for selection.

Here are 10 of the most popular applications showing how robots improve productivity, quality and workplace safety in a diverse range of industries, including arc welding, spot welding, laser welding, laser cutting and twin-wire welding.

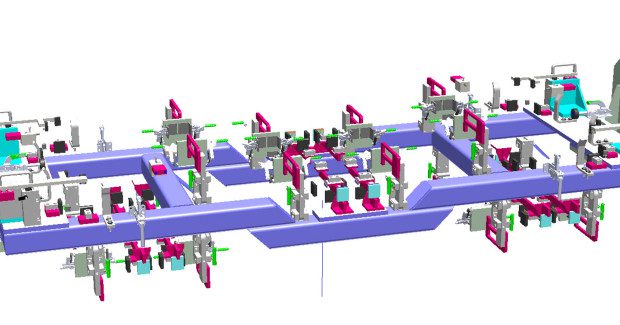

Today more than ever before, time to market is key. Utilizing the 3D world efficiently through tools such as our RobotStudio simulation programming software will enable your company to concept, quantify and qualify with confidence a new product introduction. This could be a variation of an in-house product or a competitive bid to a new customer. It could also bring a product onshore, reducing the company’s risk and supporting your output capability.

MECHANICS OF PROCESS CONTROL ON THE FLOOR

The goal for any robotic welding solution is to keep the arc burning, bearing in mind there is a direct correlation to profitability. Any technique, procedure or methodology that supports this is going the make the cell more productive and directly impact the bottom line.

The robotic cell concept itself must be in tune with your company’s manufacturing requirements. If there are projects that come and go through the season, one philosophy would be to have the fixturing permanently mounted on both sides of a rotational positioner (see Figure 2). When the job is active a fixture is presented to the robot from one side of the positioner. When the job is no longer active the other side of the positioner can be used to present the new fixture to the robot for production.

Storing the fixture when not in use is more common. By using the concept of programmed targets attached to work objects, the changeover time is accurate, quick and efficient. Re-teaching the work object allows the fixturing to be placed in different stations within the cell or indeed on another robot cell completely.

Another concept is to design fixturing to accommodate multiple components. Switching between variants can be accomplished by manual intervention (resetting the tool and calling a new program), or by using proximity sensors, the tool itself will tell the robot which component is present and the robot will react accordingly.

One further methodology for fixturing is to pre-tack the components outside the robot cell. This places an emphasis on the tacking fixture and the welder to place quality repeatable tacks on the component. The upside of this approach is that it reduces the complexity and cost of the robot welding fixture, and opens the access from the robot to the component.

FLEXIBILITY AND CAPABILITIES OF WELDING

Fortunately, the perception that robotic cells require large volumes of the same component to be efficient is slowly fading. Through much improved software and sensor technology robots have become far more flexible.

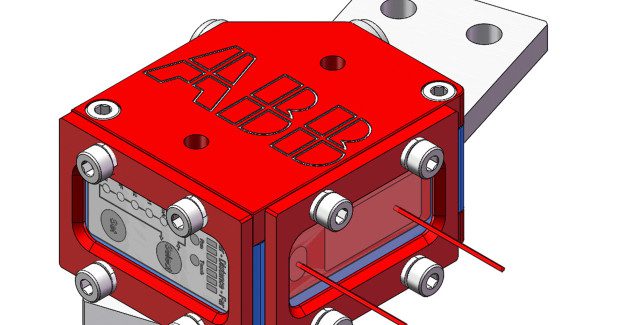

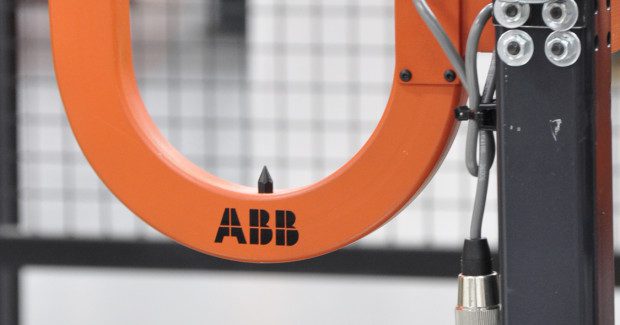

Tactile sensing and simple 1D lasers (see Figure 3) reliably automate the locating of parts and moving joints. The technology of through-the-arc tracking allows the robot to track a joint that changes position and size during the weld. Today vision and laser technology are very reliable methods of accurately defining more complex joints and part geometry.