Conveyor Removes Tramp Metal Fines

Bunting® Magnetics has a new line of high-intensity separation conveyors that provide extremely high magnetic field to separate work-hardened 300 series stainless steel from the product stream, increasing separation effectiveness for medical waste and automotive and electronic scrap recycling.

Posted: October 29, 2013

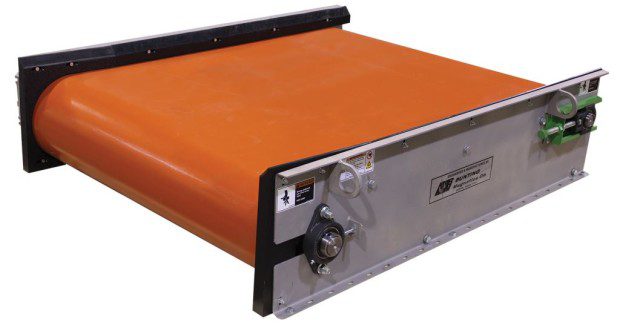

Bunting® Magnetics Co. (Newton, KS) will feature its new line of high-intensity separation conveyors that are designed to provide extremely high magnetic fields, which enable removal of lightly magnetic tramp metal fines. High-intensity magnetic fields also separate work-hardened 300 series stainless steel from the product stream, increasing separation effectiveness for medical waste, as well as automotive and electronic scrap recycling. Optional vibratory feeder trays are available. The conveyor frames are constructed of 300 series stainless steel, and tough urethane endless belts maximize magnetic field exposure to the material being conveyed.

Bunting has also released a new catalog dedicated to material handling products for the metal stamping industry that details Bunting solutions for material handling, with specific recommendations for improving efficiency in the metal stamping industry. The new specialized catalog provides metal stamping engineers and plant personnel with a comprehensive portrait of the options available to handle and convey material. Bunting material handling products are available in custom and standard product designs. This detailed booklet should become a standard reference on every plant engineer’s shelf. www.buntingmagnetics.com