Deburr Both Sides of Drilled, Punched or Reamed Holes in One Operation

The high quality M-2, high speed cutting steel Burr-Zit clothespin type deburring tool from Whitney Tool can de-burr up to five thousand holes per grind with approximately 6 to 20 grinds per tool, depending on size for unmatched performance and economy.

Posted: October 31, 2013

Whitney Tool Company (Bedford, IN) recently took a leadership position in the manufacture of deburring tools through the acquisition of Cogsdill Enterprises, Inc. (Commerce Township, MI). Cogsdill is the developer and patent holder of the Burr-Zit tool.

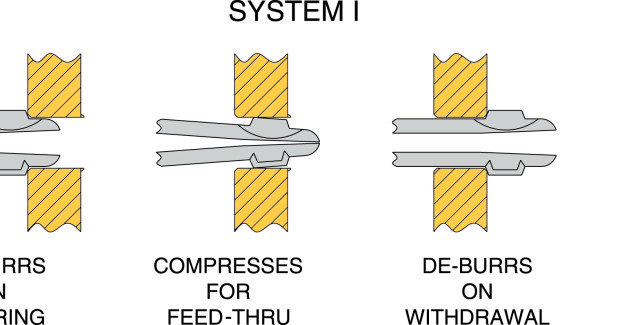

Burr-Zit is the original clothespin type deburring tool that can deburr both sides of a drilled, punched or reamed hole in one operation, even when only one side is accessible.

Burr-Zit tools are constructed from a single piece of high quality M-2, high speed cutting steel. Users can de-burr up to five thousand holes per grind with approximately 6 to 20 grinds per tool, depending on size for unmatched performance and economy.

A demonstration of how the Burr-Zit™ deburring tool makes formerly inaccessible areas accessible, and dramatically reduces production costs. Between 3,000 and 5,000 holes can be deburred with a single standard tool before reconditioning is required. Optional coatings increase tool life even more. Single side deburring (front or back) as well as countersinking options are available.

Whitney is recognized as a leading manufacturer of Woodruff style slotting and keyseat milling cutters, counterbores, counterbore pilots, T-slot, dovetail and other specialty milling cutters, as well as combined drills and countersinks. bob@whitneytool.com, www.whitneytool.com