Intuitive, Integrated and Mobile NC Simulation Software

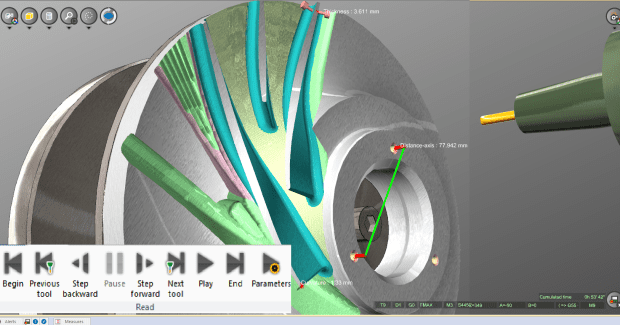

NCSIMUL Machine 9 NC simulation software from SPRING Technologies is more realistic, intuitive, integrated, and mobile with extended features dedicated to multi-axis and multitasking machining centers that interconnect with other company-wide software systems, such as MRP, ERP, and MES.

Posted: October 31, 2013

SPRING Technologies (Cambridge, MA) will demonstrate its NCSIMUL Machine 9 NC simulation software that is more realistic, intuitive, integrated, and mobile with extended features dedicated to multi-axis and multitasking machining centers. Further, the software package has been developed to interconnect with other company-wide software systems, such as MRP, ERP, and MES.

“This is the first time we are demonstrating NCSIMUL Machine 9 to western U.S. manufacturers. The latest version is much more than simply previewing toolpaths to avoid crashes,” said Silvère Proisy, the U.S. general manager. “It offers users a unique experience where CNC realistic simulation, integrating all machine, tools, and material parameters, quickly becomes a day-to-day part of a manufacturer’s lifestyle. Once again, SPRING is taking the lead in new technology enhancements and will show the mobility aspects of the software using a tablet PC. More than 200 improvements have been implemented based on extensive customer surveys.”

SPRING is a Microsoft-certified “Gold” partner and an INTEL Software Partner. As such, NCSIMUL Machine 9 incorporates new ribbon technology navigation, enabling users to work more efficiently. Tasks are now accessed via tabs that break down into tasks and sub-tasks. The new interface has been specifically designed to work on touch screen devices to facilitate mobility. The intuitive and context-sensitive icons are presented as a rapid access bar, boosting programming productivity.

NCSIMUL Machine 9 pushes the limits of CNC simulation, integrating the latest available INTEL and Microsoft technologies (multi-core, multi-threading and Windows 8 PRO touch-screen features…), whatever the complexity of your NC machines: 5 axis machine-tools, robots and multi-machines environment. The “NCSIMUL Machine hub” apps enable users to browse any shared jobs or replay NC simulations with one-click. Flexible project-based management, tree organization, project/article/sub-article, jobs copied between projects, simplified search mechanism, job templates are among the new features in NCSIMUL Machine 9. The software makes full use of Intel’s multi-core processors and multithreading. Collision detection and material removal calculations are performed simultaneously. Algorithms have been revised and optimized to support ISO decoding, probing, material removal with tools in 3D, and optimized cutting conditions.

NCSIMUL Machine 9 also provides new interactive programming features that automate G-code generation from 3D motions or allow dynamic editing of the NC program to see the consequences in the 3D view. In addition, the newest 3D functional dimensioning module, particularly geared to sub-contractors enable users to add 3D graphics to workpieces and create a document describing the list of dimensions that need checking at each machining stage. This is a significant step forward towards a paperless factory. www.springplm.com