High Precision HMC Handles Extremely Heavy Workpieces

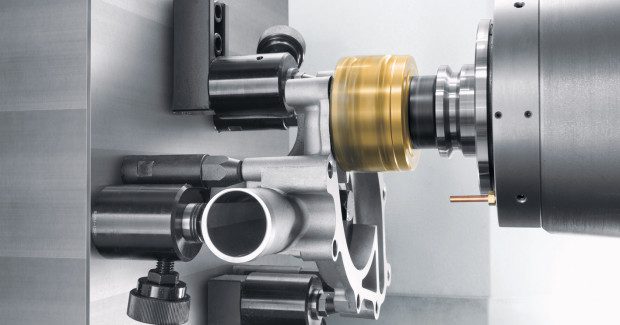

The heavy-duty NHX4000 horizontal machining center from DMG Mori ideal for machining 24.8 in x 35.4 in workpieces that weigh up to 880 lb.

Posted: November 26, 2013

The NHX 4000 has an impressive low power consumption that reduces operating costs by decreasing energy demand up to 50 percent. The low number of servo motors, as well as the LED illumination, contributes to this as much as the hydraulic aggregate with pressure accumulator, whose pump is automatically stopped in standby mode.

The working area of the NHX4000 reflects the high precision demands made in a circular accuracy of < 1.7 μm, with 1.3 in/sec feed in X and Y, as well as a 3.9 in radius to go hand-in-hand with impressive speed and dynamic values. The linear axes travel at speeds up to 39.4 in/sec, with acceleration values up to 9 m/s².

This machine tool uses a MAPPS IV high tech control with 10.4 in TFT display and optional CAM module (Esprit) along with a Siemens 840D operational control.

The NHX4000 from DMG Mori (Hoffman Estates, IL) offers cutting capacity equivalent to the NH model, with improved features for greater productivity and efficiency. It is ideal for horizontal machining of workpieces of up to 24.8 in x 35.4 in, with a loading capacity of up to 880 lbs.

The NHX machine concept is based on the successful NH series with more than 6,000 machines installed worldwide. The success of the series will also be continued by the company with the NHX4000 with respect to the perfect combination of functionality, productivity and precision.

This overall performance at BestPrice focuses on a compact design of just 12.5 m². Christian Thönes, a board member of Gildemeister AG, says, “The NHX4000, with its tiered traveling column and a multitude of additional innovative features, is a top-class horizontal machining center.”

The workpiece range of the NHX4000 with 400 kg pallet comprises workpieces up to 25 in diameter and 35 in height. In the work area of 22 x 22 x 26 in (in X × Y × Z) the horizontal centre machines the components extremely accurately and efficiently.

http://youtu.be/7SOOY_zXoM4

A demonstration of the rigid, accurate NHX4000 horizontal machining center, with 18 percent lower power consumption. Its robust bed and powerful table and pallet clamping force offer stability, while the high-output spindle makes for fast metal-removal rates. This machine tool is also now built in America at the DMG Mori manufacturing facility in Davis, CA.

The high demands made on the precision of the NHX4000, which is among other things reflected in a circular accuracy of < 1.7 μm, with 1.3 in/sec feed in X and Y, as well as a 3.9 in radius to go hand-in-hand with impressive speed and dynamic values. The linear axes travel at speeds up to 39.4 in/sec, with acceleration values up to 9 m/s².

In the process itself, users can choose from spindle rotational speeds in the standard version of up to 12,000 rpm and a torque of 110 Nm. The high-tech module optionally also provides an 12,000 rpm spindle with 30 kW.

The tool management of the NHX4000 is equipped for all requirements. The standard version of the machine has a ring magazine with a capacity of no less than 40 pockets, which can optionally be extended to 60 pockets.

The fast tool changer impresses in all versions, with a chip-to-chip time of just up to 2.8 seconds. Together with pallet changing time of 8 seconds, the shortest idle times are guaranteed.

Apart from the considerable performance in the process, the NHX 4000 also impresses with its low power consumption and reduced operating costs compared to previous models. It has been possible to decrease energy demand by up to 50 percent. The low number of servo motors, as well as the LED illumination, contributes to this as much as the hydraulic aggregate with pressure accumulator, whose pump is automatically stopped in standby mode.

Features of the NHX4000 include:

- 15.7 x 15.7 in and 881,8 lb pallet load

- 8 m/s² acceleration (Y-axis)

- 2.5 μm positioning accuracy

- 1.7 μm circular accuracy

- 2.8 sec. chip-to-chip time

- 450 mm (17.7 in) max. tool length

- DCG III® (drive near the centre of gravity) ensures low vibration, highest dynamics and precision

- Direct measuring systems by Magnescale in all axes as standard

- Energy efficiency: Electricity savings up to 40 percent compared to previous model

- High-tech controls: MAPPS IV with 10.4 in TFT display and optional CAM module (Esprit) as well as Siemens 840D operate