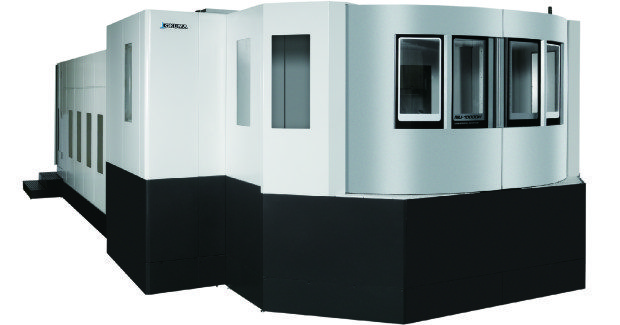

Large 5-Axis Horizontal Machining Center for Difficult Applications

Okuma‘s largest 5-axis CNC horizontal machining center has a large trunnion table with one m square pallet and has a maximum work piece weight capacity of 5,500 lb.

Posted: November 26, 2013

The MU-10000H from Okuma America Corporation (Charlotte, NC) is the largest of their MU range of 5-axis horizontal high-speed machining centers, with a large trunnion table with one m square pallet that has a maximum work piece weight capacity of 5,500 lb and work piece size capacity of 59.05 in diameter by 44.29 in high.

This workhorse machine delivers high torque and high-speed machining along with Okuma’s renowned high standards of design stability and accuracy. Designed for the most difficult applications, the MU-10000H provides the end-users with a long-lasting efficient production platform.

A demonstration of the largest of the MU-10000H 5-axis horizontal high speed machining center. The data for the cut shown here is Material: Steel 4140; Spindle Speed: 229; Feedrate: 23 ipm; HP: 56; Cutting tool: Sandvik 245 – 8 inch 45-degree lead facemill; Cutting torque: 1,284 ft-lb; Depth of cut: 0.375 in; Width of cut: 6.0 in.

The machine is equipped with the THINC®-OSP P200MA control. The THINC-OSP P200MA provides a seamless, fully integrated 5-axis system with all the advantages of the THINC control, including advanced high speed contouring with Okuma’s Super NURBS. Okuma’s Collision Avoidance System (CAS) is also available as an option.