Robot Loads Deep Drawn Parts Into Press

Triform Sheet Hydroforming and Beckwood Press demonstrate sheet hydroforming with 3D tools and simulation software in action, along with robotic automation to tend the machine tools.

Posted: November 13, 2013

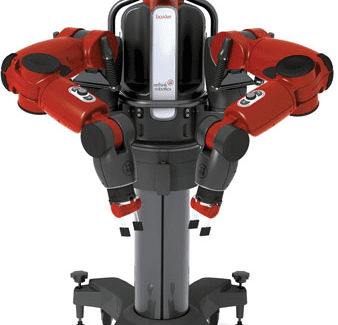

Beckwood Press Company and Triform Sheet Hydroforming (St. Louis, MO), leading manufacturers of custom hydraulic presses, automation systems, and next-generation Deep Draw and Fluid Cell sheet hydroforming presses, have tasked Rethink Robotics’ Baxter with automatically loading deep drawn parts – formed in the booth within a Triform press – into a Beckwood hydraulic press for final trimming.

During development, the operator has the unique ability to open the chamber at chosen points in the cycle in order to visually inspect the partially formed part. This allows the operator to target portions of the recipe potentially causing wrinkles or tears without much of the guesswork associated with analyzing a fully formed part. Once the visual inspection is complete, the operator has the option to abort the cycle, to adjust subsequent recipe steps before continuing the cycle or to continue the cycle without making adjustments to the recipe. If continued, the chamber once again closes and the cycle is automatically resumed at the point (pressure and position) at which it previously opened.

The Triform 610-20-3SC is a 20,000 psi deep draw sheet hydroforming press associated with inexpensive tooling and advanced forming capabilities. Triform’s Deep Draw technology is the ideal solution for applications that require a controlled flow of the material, such as those with curved or otherwise complex geometries. info@beckwoodpress.com, www.beckwoodpress.com, www.triformpress.com