Small Investment in Trunnion Tables Rewards Big in Productivity

Bolt-on trunnion tables from MMS help Indelac Controls reduce setups on Haas VF4 VMCs from six to two and cut cycle time by 40 percent, while delivering a 100 percent ROI in just days.

Posted: November 12, 2013

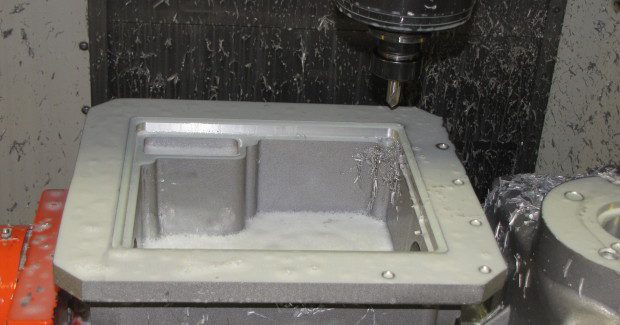

Indelac Controls Inc. (Florence, KY) turned to a nearby source, TrunnionTables.com (Elsmere, KY), for a workholding solution that had immediate impact on the shop’s productivity, cutting cycle times by 40 percent and eliminating batch processing that required work in process. Bolt-on trunnion tables were installed in minutes on the fourth axis indexers of the company’s two Haas VF4 vertical machining centers, producing a 100 percent ROI within days.

The two machines now mill, drill, tap and even do light contouring on Indelac’s 319 aluminum castings with 66 percent fewer part setups. Time-consuming part locating, previously required to meet accuracy requirements of 0.0005 in, was also eliminated without compromising part quality.

“We were pleasantly surprised to see that something so simple could exploit the fourth axis on our machines and have such a dramatic impact on our business,” said Bill Robinson, the shop foreman for Indelac Controls. “We can now produce the same number of parts in a day that may have taken a week using our old methods.”

Indelac Controls manufactures a variety of electric actuators, including: quarter-turn, multi-turn, spring return and linear. The actuators are used in wastewater treatment facilities, power plants, refineries, pipelines, oil and gas exploration and a host of other process automation applications. Today’s actuators have advanced functions that go beyond simple open and close capability.

Here is a demonstration of a Stallion Trunnion Table in action on Haas vertical machining center. MMS manufactures trunnion tables for any rotary table on the market today, with standard size trunnions measure 9 in x 20 in and 9 in x 23 in, are cast from class 35 cast iron with a special mix for toughness and durability. We make special sizes everyday up to 40 in x 20 in. Specials are standards for us.

Some are packaged with position sensing equipment, torque sensing, motor protection, logic control and digital communication. These hi-tech functions make accuracy of the housings critical to proper function, so Indelac has always produced its machined parts with an accuracy of 0.0005 in, though its process methodologies made this time consuming and labor-intensive. Indelac’s need for accuracy required frequent indexing off of previously machined features using “homemade” fixtures, clamps and angle plates.

“On top of everything else, locating on cast parts is more difficult because the surfaces can vary greatly from part to part,” said Clay Huff machinist at Indelac. Multiple part setups had driven cycle times at Indelac up to 50 minutes or more and parts were batch processed, created stage by stage over a series of operations. “Some of our housings require machining on all six sides, and with our previous workholding methods that meant six separate setups,” said Huff.

“I knew Stan Martin (president of TrunnionTables.com) and he came in and looked at our operation and immediately said they could help us,” said Robinson. “We worked with Stan and his team to setup our VMCs with CNC trunnion tables and improved fixturing so we could produce these parts in a maximum of two setups. The tables transformed our manufacturing process the minute we got them on the machines.”

Indelac purchased two custom-made tables and four fixtures from the firm, as well as a standard model Stallion 9\23 – a double-sided table with quick-change plates – that is compatible with most vertical machines. The quick-change plates allow one-minute changeovers and 0.0005 in repeatability. The new trunnion tables and fixtures use locator pins to position and hold the part, ensuring part-to-part consistency and hitting Indelac’s high accuracy standards with less effort.

Huff routinely checks every fifth part with a CMM to close the quality control loop. Fewer setups and part handling have made hitting the accuracy tolerance a faster, easier enterprise. “With the old fixtures we had to indicate repeatedly to make sure we had it right. My life is a lot less stressful now that we have the trunnion tables,” Huff added.

With the new trunnion tables the company was able to implement continuous production and improve its cost-per-part numbers by decreasing manufacturing costs and increasing finished part production. “Our cycle time is down to about 30 minutes with the trunnions compared to 50 minutes or more with our old fixtures, and we get a finished part off every time we hit the cycle start button,” said Robinson. “We’ve reduced cycle times and eliminated WIP, so if a quick-turn order comes in we can setup the machine, run the part and get it out the door.”

Ninety percent of Indelac’s parts can be run using the new workholding devices and the days of manual clamps, angle plates and plugs are over at the shop. “Compared to purchasing a $300,000 five-axis horizontal machine, spending a few thousand to get the most out of our four-axis verticals is the deal of the century,” said Robinson. “Sometimes the simplest, least expensive method produces the desired results and that’s what we found with these trunnions.”

Indelac Controls Inc., 6810 Powerline Drive, Florence, KY 41042, 859-727-7890, www.indelac.com.

Martin Machining Services Inc., 602 Main Street, 859-727-9900, Elsmere, KY 41018, www.trunniontables.com.