CAM Upgrades Keep Manufacturer in Growth Mode

The decision that CAR Engineering and Manufacturing made to upgrade its Mastercam software has had a widespread incremental impact on what has turned out to be a record growth year for the company.

Posted: November 11, 2013

Yvette Pagano, president of CAR Engineering and Manufacturing, Inc. (Victor, NY) lives in a bifurcated manufacturing world. Half of the income generated by this 50-person job shop derives from the company’s regional leadership in multi-slide production metal stamping. This is as it should be, since excellence in the field of metal stamping was the intention of Yvette’s father, Charlie Rogers, when he founded the company in 1986.

The other half of the business is dedicated to precision CNC manufacturing with a dozen 3- and 4-axis CNC mills and 10 CNC lathes serving a diverse base of companies in the aerospace, defense, medical, and consumer goods industries. This CNC stream of business was initiated early in the previous decade by the former company president who had considerable expertise in CNC manufacturing along with good relationships with potential customers. Today, a wall runs through the center of CAR Engineering’s plant, with separate staff and equipment on either side, serving their own unique customers.

The upside of having two manufacturing disciplines under one roof is that the revenues frequently offset each other. When one side of the business is down, the other may be up. In addition, having a support staff divided between two businesses tends to reduce costs. The downside is that a finite budget for equipment and software must be divided between two robust businesses with entirely different needs. Each investment decision must be made with extra care so that both businesses can have the resources they need.

http://youtu.be/3r0DAhxKWTQ

Here is a demonstration of Mastercam CNC programming software applications.

Late in 2011, when CNC Project Engineer Steve Gerrard asserted that his department needed to have an upgrade from their Level 1 Mastercam Mill Software to Mill Level 3 with Solids, Pagano weighed the request very carefully and agreed. That decision has proven to have a widespread incremental impact on what has turned out to be a record growth year for the company.

CAR Engineering purchased its seat of Mastercam Mill Level 1 software in 2005 because it was the only CAM software taught at the locally at Monroe Community College. It was also the brand of the CAM experience stated on nearly every application the company received for employment. If they were going to avoid a steep CAM software learning curve in the Rochester market, then it would be important to use the software nearly every applicant already knew.

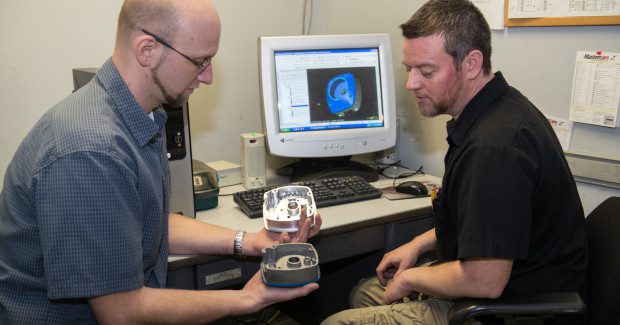

The company installed Mastercam Mill Level 1 software in a computer room adjacent to the shop floor. It is in almost constant use by Dave Schutt, the primary CNC programmer, and several others who have received training and ongoing support from Optipro Systems, the nearby Mastercam Reseller.

Pagano explained, “By 2012, we had reached a threshold where we were having difficulty keeping pace with the programming for all of the work that was coming in. Plus, we had to turn down some complicated surface milling work, not because our equipment was deficient, but because we were unable to generate the programs with our Level I software. Steve was becoming frustrated, particularly since he had used the Mill Level 3 software in his previous job and was confident that it would improve our situation in many ways. He was right.”

One of the biggest improvements the company realized immediately was a reduction in the “No Quote” jobs it was returning to its customers. CAR has some very sophisticated high-tech customers who are reluctant to split families of parts between multiple suppliers. “If there are 60 parts in a family and we can’t quote a couple because the programming is too difficult, then we typically won’t get any of them. It’s a 60 or 0 proposition with the loss of one part resulting in the loss of many. We have significantly reduced the incidence of “No Quote” jobs in 2012.”

“We’ve seen a dramatic increase in productivity because of all the different options that come with Mill Level 3,” says Pagano. “For example, we had been running one job for a big customer of ours using a program written in CAM software that we used before obtaining Mastercam. After purchasing Mill Level 3, we rewrote the program and because of all the enhancements that come with the upgrade, we were able to save 50 hours on the same job. Based on this time savings alone, the software has already paid for itself.”

The productivity gains for this job were due to the elimination of air cutting time compared to Mastercam, which uses a dynamic model of the part to ensure that the cutting tool is almost always in contact with it. The previous machining cycle for one part was 40 minutes. Rewriting in Mastercam with Solids brought the total time down to 22 minutes.

CAR Engineering routinely uses Mastercam’s simulation features, Backplot and Verify, to check clearances and material removal. For complex parts, they can now do an even more precise check by generating an STL file of the CAM file and comparing it directly to the CAD model. Color-coding of this comparison file reveals even minute discrepancies (e.g. a hole has been programmed for drilling but the reaming step was skipped.)

With this procedure in place, some of CAR’s customers have allowed the company to restrict physical first piece inspection of the part to critical features only. In one instance, this eliminated three hours from the inspection procedure in the QC lab, which frequently has queues of work lined up from both the stamping and CNC sides of the business. This CAM-based verification allowed the shop to get its part through the lab and into production sooner.

With Mastercam Mill Level 3 with Solids, all the programmers can have more powerful tools for defining manufacturing processes, specifying tooling, designing workholding solutions, and refining production programs to reduce cycle time. These aspects of the job are very closely defined early on instead of incrementally over a number of production runs.

When the job comes up again, and modifications need to be made to the program, these can be handled by less experienced programmers or set-up technicians. This has allowed CAR Engineering to consistently allocate time spent by its most talented CAM users to highest priority projects and opportunities for growth.

On the stamping side of the business, quotes are calculated based on the amounts of material processed, because these can be very expensive. On the machining side, quotes are all about time. Pagano said, “We are machining mostly aluminum and stainless steel. Material is not a big issue on this side of the business (unlike stamping). So profitability has to do with the labor and the time required to get the parts done. That’s where you are winning and losing. Mastercam Mill with Solids has definitely cut down our time to get a good part out of the machine and provides better tools for avoiding quality mistakes.”

“I am happy that Steve Gerrard was very assertive in advocating for this addition,” Pagano concluded. Of course, this makes her job as budget adjudicator a little more difficult since Gerrard is also advocating for the purchase of a 5-axis CNC machining center along with Mastercam 5-axis software. Based on the time savings, he may just have another winning argument.