An Intelligent Revolution in Welding

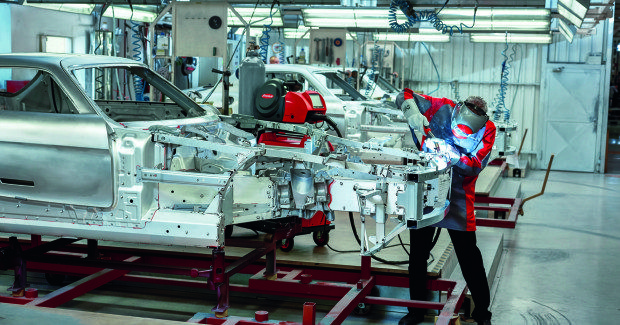

The Fronius Trans Process Solution (TPS/i) welding platform allows welders and maintenance technicians to work more efficiently and create the best quality weld for a job.

Posted: December 17, 2013

The new Fronius Trans Process Solution (TPS/i) welding platform from Fronius USA, LLC (Portage, IN) boosts welding technology to a new level with intelligent technology and advanced system communication that produces the best arc in its class.

Featuring the industry’s first-ever touch screen, TPS/i empowers welding technicians to focus on the weld rather than the machine by providing a more accurate and stable arc, better penetration, higher efficiency, and noticeably less spatter. TPS/i 300A, 400A and 500A models are now available, with a 600A model to launch in 2014.

“This leap in welding technology is the fruit of the biggest innovation project in the history of Fronius,” said Gerald Obritzberger, the director of sales and marketing at the Fronius USA Welding Technology Division. “Welders benefit from working with customizable and upgradeable appliances that stand out for improved user experience and extensive communications functions. The TPS/i does just that, allowing welders and maintenance technicians to work more efficiently and create the best quality weld for a job.”

Take a look what some users say about the new Intelligent Revolution from Fronius, the TPS/i. One moment the TPS/i is still a standard welding machine, the next it has been upgraded into a pulsed-arc power source. The TPS/i interacts intelligently with the user. The high-speed system architecture means that the arc can be measured and analysed more accurately, enabling it to be better understood and controlled.

PLACING USER FOCUS ON THE WELD, NOT THE MACHINE

The TPS/i boasts a sturdy, 7 in plain-text touch-sensitive display and user interface which allows welders and maintenance technicians to easily and clearly organize the system settings and spend more time focusing on the weld itself.

Internal communications within the machine include advanced job memory and wire regulation with penetration stabilization to automatically change wire feed speed. The process control system routes arc feedback and control at 100 MB per second, faster than any welding platform currently available.

The SpeedNet high-speed bus that links system components to the power source transmits data much faster than its predecessors, ensuring short reaction times and superior control.

The controllability of the wire feeder helps to achieve even better results at the end of the welding operation as the wire electrode is retracted at the same time the welding current is limited, effectively preventing both droplet formation (otherwise unavoidable) and spattering.

These optimizations benefit the standard welding process as well as two new weld processes made possible by the TPS/i’s integrated intelligence and high-speed control circuitry. The dip-transfer arc process LSC (Low Spatter Control) stands out for its previously unobtainable low tendency to spatter and for its exceptionally high process stability. The Pulse Multi Control (PMC) permits significantly higher welding speeds in pulsed-power welding, yet with optimum droplet detachment.

INNOVATIONS THAT WORK

Welders and maintenance technicians depend on the welding platform to easily, smoothly, and safely operate. Working with the innovative touch-screen interface on the TPS/i is as simple as operating a smart phone. Fronius’ major design advancements on the cooling dock enable a single operator to simply manage, attach and remove the dock on the work site.

An exclusive FSC connector on the torch protects all lines from the working environment to reduce accidents and maintenance time. The design advancements featured on the Fronius TPS/i work in cooperation with the technical communication and data enhancements.

“TPS/i opens an unprecedented degree of individuality and interactive possibilities to users,” adds Obritzberger. “Its features complement the welder or maintenance technician’s skills as they complete complex and varying tasks efficiently and with consistently high quality. The TPS/i’s built-in intelligence and end-to-end modularity provide a firm foundation for future innovations, ensuring high security of investment for years to come.”

Fronius USA is a subsidiary of Fronius International GmbH, is headquartered in Portage with sales offices in Michigan and Tennessee. Fronius manufactures an extensive line of welding power sources, solar inverters and battery chargers. The company’s Welding Technology Division is one of the world’s technology leaders in the arc welding market segment and continues to drive welding innovation. www.fronius-usa.com

Fronius International is an Austrian company with headquarters in Pettenbach and other sites in Wels, Thalheim, Steinhaus and Sattledt. With over 3,239 employees worldwide, the company is active in the fields of battery charging systems, welding technology and solar electronics.

Around 93 percent of its products are exported through 19 international Fronius subsidiaries and sales partners/representatives in over 60 countries. With its innovative products and services and 864 active patents, Fronius is a world technology leader.