Making Natural Gas Clean with a “Hole” Lot of Pressure

Using a modified HMD915 magnetic drill and Industrial Series of Rotabroach Cutters from Hougen enabled Mueller Environmental to cost-effectively develop a patented new system for cleaning natural gas.

Posted: December 5, 2013

When it comes to energy there’s no denying that it’s a part of our everyday lives. But when we turn on a light, turn up the heat or fill our car how often do we think about how the energy got there?

One everyday source of energy is natural gas. Natural gas is used in everything from cooking, heating, cooling, energy generation, transportation and more. But the natural gas that is extracted out of underground wells is quite different than what we use in our homes and businesses. Gas out of the ground is dirty. It contains a variety of undesirable liquids and solids that must be removed before it is pumped to processing and distribution stations. Unclean gas can quickly ruin millions of dollars in equipment.

The old method for cleaning the gas used large paper filters in special pressure vessels. These filters had to be changed regularly depending on how dirty the gas was. Sometimes as often as every eight hours. This can be a very time consuming and environmentally costly process.

Now, however, one company located outside of Houston Texas has changed the way natural gas gets cleaned. Mueller Environmental Designs, Inc. (Houston, TX) has been manufacturing a patented helical separator system that eliminates virtually all of the solids, water, oil, black powder and a variety of contaminants from the natural gas. Their separator delivers clean natural gas for processing and distribution.

A demonstration and overview of the HMD915 magnetic drill for holes up to 3 1/16 in diameter and 3 in deep. Includes positive slug ejection and through the tool coolant.

PROBLEM

The pressure vessels Mueller Environmental manufacturers measure anywhere from 4 to 8 feet in diameter and are made from ½ in to 3 1/2 in thick 5617 rolled steel plate. The diameter and material thickness depends upon the pressure the vessel must withstand. Sometimes pressures can reach as high as 3,000 psi.

Inside the vessels is a proprietary gas cleaning separator and an area to hold the accumulated solids and liquids that are removed. This material is drained automatically as it fills up the holding area. To measure the amount of waste material inside the tank, Liquid Level Indicators must be installed. There are two level indicators, a low level indicator roughly 1 in to 2 in off the bottom of the tank and a high level indicator located in the middle of the tank.

Holes must be drilled into the vessels for the level indicators. Drilling a hole in the center of a large pressure vessel can present its own set of challenges, but nothing like the challenges of drilling the radically angled hole at the bottom of the vessel. These holes range from 1 in to 2 in diameter.

For years the method that was used to drill the lower level holes was an old mag drill with a drill chuck and twist drills. Starting with a 3/8 in twist drill, a pilot hole was drilled. Then a 5/8 in twist drill was used to enlarge the hole. Next the hole was enlarged to ¾ in. This process continued until the proper hole diameter was achieved. Depending on the hole angle and location, sometimes arc gouging and grinding to finish the hole was needed. The entire process took eight to twelve hours per hole. Each vessel requires two holes. A very time consuming operation to drill a hole.

SOLUTION

After Mueller Environmental opened their new manufacturing facility a couple years ago, plant manager Mark Allen said, “One of my jobs when I took over was to reduce the time we spent on some of our operations. As we all know, time is money.” One operation that was taking an extreme amount of time was the lower level holes being drill on the pressure vessels. Allen knew “there had to be a better method.”

After some research, Allen eventually contacted Hougen Manufacturing, Inc. (Swartz Creek, MI) and had their local sales rep, Terry Fuller, take a look at the application to see if they could help. “When Mark drew the hole on the end of the rolled steel to show the angle of cut, I took a step back,” recalls Fuller. “A severely interrupted hole like this on the side of a curved vessel was not something of an everyday application.”

After taking notes on what needed to be done, Fuller returned with a standard Hougen HMD915 magnetic drill and a couple of Rotabroach® cutters. On a thinner walled vessel, Allen had his guys weld a platform that was perpendicular to the angle that needed to be drilled. The platform would serve two purposes, one for the mag drill to magnetize to and number two: the plate would act as a guide bushing for the cutter to drill through and into the edge of the vessel.

The test was successful, drilling through the wall of the vessel and on the proper angle without a problem. But looking ahead at future projects the depth of cut on the larger vessels was going to be up to 8 in deep. Standard Rotabroach cutters are available up to a 6 in depth of cut.

The test information was taken back to Hougen. Their engineers decided to take a stock HMD915 mag drill and increase the stroke from a standard 3 in to 6 in to accommodate a larger Rotabroach Cutter. With this extra stroke, on the vessels requiring a one inch hole, Mueller Environmental could use a 6 in depth Rotabroach to drill straight through.

On the 2 in diameter holes and through the 3 in thick side walled vessels, a step up method of drilling could be utilized. This means drilling down with one depth of cut tool, then using a longer depth of cut tool, continue drilling the rest of the hole. For deep holes this lessens the horsepower needed and helps in chip extraction when the cutter is deep in the hole.

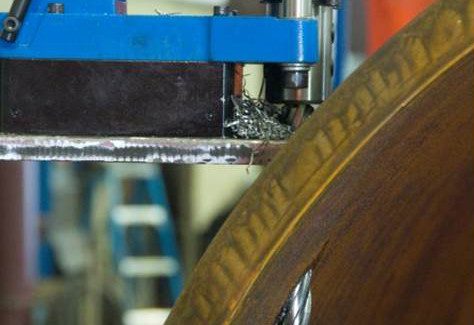

Hougen suggested using their Industrial Series of Rotabroach Cutters that offer a thicker cutter wall for increased durability, patented tooth geometry for the long deep cuts and extended resharpenability. Special, custom 2 in diameter by 8 in depth Rotabroach Cutters were made to drill through the longest areas with the most extreme angles.

When it came time for the next pressure vessel, Allen and his team at Mueller Environmental put their new method to the test. Using the modified HMD915 magnetic drill and the Industrial Series of Rotabroach Cutters, they went to work. The first holes needed where 1 in diameter holes through 2 in thick side wall vessel. The guide platform was welded on and everything was aligned. The HMD915 drilled down through the plate, into and through the side wall of the vessel in 20 minutes, saving Mueller eight hours of time per hole.

The next vessel required 2 in diameter holes drilled through a 3 in sidewall with a total drilling depth of 8 in. Once the guide plate was setup, they drilled through the guide plate and down 3 in. Next, a 6 in cutter was inserted in the hole and continued drilling down until the cutter bottomed out. Finally, the custom made 8 in Rotabroach cutter was inserted into the hole and the hole was completed. Total drilling time took only 45 minutes. This saved Mueller 12 hours per hole.

Allen and his team at Mueller Environment were ecstatic with the time savings they have achieved. “It’s not only the time savings we are experiencing but also the quality of the hole,” smiles Allen. “The hole is round and true with a great finish. We get more accurate readings from our level indicators now, it’s much easier to stay within tolerances, and the tool will pay for itself.”

With the success of their patented system to clean the natural gas, and the time saving efforts of Allen and his team, Mueller Environmental looks at increasing production by the end of the year. “Hougen has been a big problem solver for us. We’ve been able to find a better way and, in doing that, it saved us money,” notes Allen. “We hope that once we expand our manufacturing facility we will be able to bring in more of their drills, not only for use on the pressure vessels, but on other parts we fabricate as well. Having American made products is important in our business.”

Mueller Environmental Designs, Inc., 7607 Wright Road, Houston, TX 77041, 713-465-0995, Fax: 713-465-0997, www.muellerenvironmental.com.

Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, MI 48473, 810-635-7111, Fax: 810-635-8277, www.hougen.com.