A New Look at Pipeline Intervention

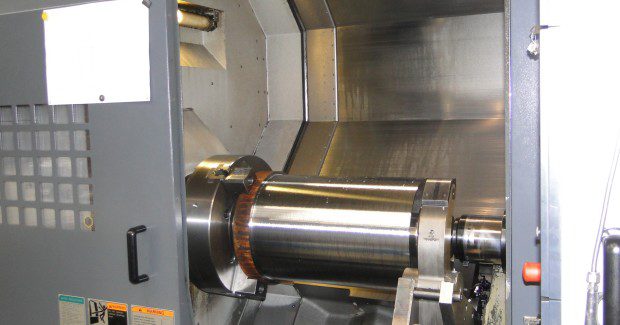

The DMG Mori machine tools used by Hunting Energy Services play a crucial role in manufacturing well intervention equipment and threaded tubulars for the oil and gas industry.

Posted: January 24, 2014

At its Badentoy site near Aberdeen, Hunting Energy Services International Ltd. (Badentoy, UK) designs and manufactures well intervention equipment and threaded tubulars for the oil and gas industry. The machine tools it uses from DMG Mori UK (Middlemarch, UK) play a crucial role in the manufacturing process, enabling it to reliably deliver high quality products to its customers.

On the tubular side, Hunting has been using DMG Mori machines since 1989 and the reliability of the SL603, SL8 and SL65 machines under very harsh cutting conditions made the addition of two SL403 machines in 2007, an NL2500 SY 700 in 2008 and a NLX2500 SY with C and Y axes in 2013, for well intervention products, an easy decision.

Iain Frater, the manufacturing manager at Badentoy, explains, “In the pipeline section, the tubes are 2.375 in to 14 in diameter and 40 ft long and they can also be slightly bent, which puts tremendous force on the machine bearings and toolpost. These machine tools run continuously six days per week and, for the two SL603 machines alone, we have processed 31,263 units through the threading line over the last 12 months. I don’t think there is another machine on the market that would cope as well as these we have in this environment.”

The SL403 was purchased to manufacture pressure control equipment (PCE) which enables the servicing of a live well for access and deployment of downhole tools. The PCE also includes a chamber for the safe recovery of downhole tools, providing protection for personnel, environment and equipment. For this application, the power of the SL403 is a big benefit, as large 16 in diameter workpieces require heavy cuts and low rotational speeds. Frater says, “We have to remove a large volume of material, so the torque available on the SL403 is very important to us.”

http://youtu.be/rPPMgQc2cu0

Here is a demonstration of the NLX2500/700 turn-mill machine tool, which is ideal for manufacturers seeking a highly accurate, cost-effective turning solution. It offers all the rigidity and precision of the original NL machines — at an even better value. The NLX2500/700 features a reduced footprint, lower energy consumption and improved cutting ability — enhancements made based on an in-depth analysis of customer needs.

A Quick Lock System which Hunting manufactures enables the snap together connection of tool string components. Previously they were connected with screw together fittings, but this was both time consuming and resulted in damage from pipe wrenches to the tool string. The NL2500 SY proved to be an ideal machine for this application enabling the company to virtually finish the product in one operation.

Originally, there was a turning operation followed by a milling operation. Now both are completed on the NL2500. “We produce batch sizes of 20 to 50 parts in three different sizes in both male and female versions,” notes Frater. “For the six products we are achieving time savings of around 50 percent, maintaining repeatability and keeping to tolerances of 0.0003 inches in 30-36 Rockwell material.”

The shop keeps a standard set of tools on the machine all set by on machine probe. It drills and machines the O/D with Kennametal tools, cuts the internal grooves with Iscar and finally mills the lobes with the side of the driven tool, transferring the part between the main and subspindle to produce a finished part.

The NLX2500 SY was purchased to increase capacity to include the machining of Variball elliptical roller products which vary in size from 1.5 in to 4.5 in diameter. These help other downhole tools to negotiate highly deviated sections of the wellbore and travel further down than would otherwise be possible. “The NLX2500 SY has given us the capacity to machine the Variball and also the opportunity to explore the possibilities of one hit machining on other products. The machine size and the subspindle specification we required were not available on other machines, making the NLX the only and best choice,” adds Frater.

The MAPPS control, which is common on all of these machine tools, makes for easy conversational programming for Hunting. The shop also appreciates the build quality of the machine tools. “The castings are more heavy duty and the guideways more rigid than on other machine tools. After 20 years, these machines will be performing as well as they were when they were new,” states Frater. “We consider the lifetime cost for the machines, and these come out as the most cost effective investment, supporting our objective of using the best machine tools and equipment available.”

DMG MORI machine tools are also used at the Houston and Louisiana sites of Hunting in the U.S. “We share information and techniques, helping us to find new ways of using the machines to further increase productivity,” smiles Frater.

Hunting Energy Services International Ltd., Badentoy Avenue, Badentoy Park, Portlethen, Aberdeen, AB12 4YB, United Kingdom, +44 1224 787000, Fax: +44 1224 787100, www.hunting-intl.com.

DMG Mori UK, 4030 Siskin Parkway East, Middlemarch Business Park, Coventry CV4 4PE, United Kingdom, +44 2476 516137, Fax: +44 2476 516136, kirsty.wilkins@dmgmori.com, www.dmgmori.com.