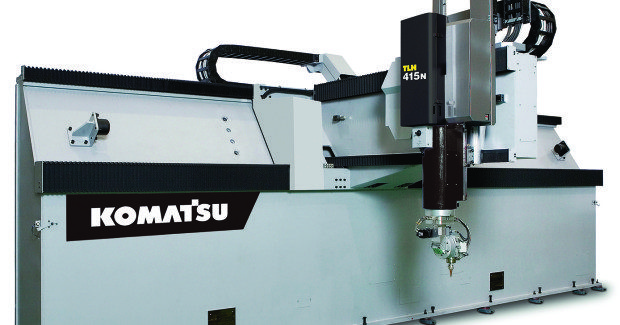

Advanced 5-Axis Fiber Laser Cutting System

The cantilever-style NTC TLH 5-axis fiber laser processing system from Komatsu NTC America achieves processing times two to three times faster than traditional CO2 and provide significant savings in operating costs. This system is ideal for hot stamping applications and high speed cutting of thin gage mild steel, aluminum or stainless steel up to ¼ in.

Posted: January 7, 2014

Komatsu NTC America (Novi, MI) has made advances to their NTC TLH 5-axis fiber laser processing systems. The cantilever-style TLH models now offer a new control system and teach pendant to allow for easier operations and use.

The controller, labeled 06R is an upgrade from the previous proprietary 05R NTC controller. The new controller provides easier to read screens with touch screen activation leading to faster processing times.

The new teach pendant response time has improved from two seconds to a half second, is ergonomically advanced for operator use and provides a safety interface to ensure that two hands are on the pendant with automatic shut off should one hand be removed. The TLH also comes with a new color scheme for a contemporary look and new Komatsu badging.

The TLH Series features two models: The TLH-414N a shuttle pallet system and the TLH-408N with a 110 in diameter rotary table. Cutting speed to 1,575 ipm (40,000 mm/min) can be achieved and the series features an IPG fiber optic generated and beam delivery system with 3 kW power option.

The fiber laser series has been shown to achieve processing times two to three times faster than traditional CO2 and provide significant savings in operating costs. It is ideal for hot stamping applications and high speed cutting of thin gage mild steel, aluminum or stainless steel up to ¼ in ( 6 mm).

Depending on the model, the TLH 5-axis series provides X, Y and Z axis travel up to 177 in (4500 mm), 45 in (1150 mm) and 20 in (500 mm) respectively with positioning accuracy of within ±0.05/500 mm (±0.002 in). Combined with its controllable optical head angles of +720 deg on the C axis and rotation of +135 deg on the A axis, the TLH models can operate in virtually all cutting applications.

This series provides two pallet options: a 4 ft x 8 ft shuttle for larger parts processing or a 110 in diameter rotary table for increased flexibility and production for smaller parts and volumes. The system uses a Windows® operating environment, non-contact gap sensor technology, controllable optical head angles, and operator friendly joystick and hand-held pendant.

In addition to the TLH Series, other NTC laser processing machines includes the TLM Series 3D, 5 axis; the TLZ Series 2D, 3-axis systems with flying optics; the TLV Series 3-axis hybrid machines for large, wide workpieces; and the TLX Series high power, 3-axis models in cantilever and gantry configurations.

Komatsu NTC America, 46605 Magellan Drive, Novi, MI 48377, 248-560-1200, Fax: 248-560-0215, www.ntclaser.com.