Optical Bend Guiding System With Laser Angle Measurement

The combination of the Optical Bend Guiding System and the Laser Angle Measuring System (LAMS) from Bystronic greatly enhances press brake operations, increases productivity and increases part accuracies.

Posted: January 7, 2014

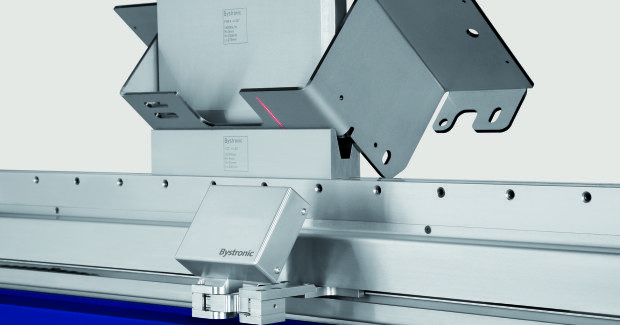

The Optical Bend Guiding System from Bystronic Inc. (Elgin, IL) encompasses LED technology that greatly enhances press brake operations and reduces setup times. The LED bar located above the tool clamping in the ram enables easier tool positioning, more effective station guiding, clear back gauge positioning, clamping open, error, and end of job indications.

http://youtu.be/_IMcDrNQeco

Demonstration of Xpert from Bystronic with Optical Bend Guiding System that provides easier tool positioning, clear back gauge position indication, more effective station guiding, clamping open information, error indication, and end of job indication.

The Optical bend guidance system guides the operator through all of the machine setup and bending sequences, reducing setup times and ensuring part quality. When you absolutely have to have the highest part accuracy from the very first bend, the Laser Angle Measuring System (LAMS) automatically positions depending on the bending station and uses a laser measuring system for each angle that is produced and ensures the highest part accuracy to within nearly a quarter of a degree of the programmed angle.

http://youtu.be/lX4zQNtPu-8

Demonstration of how, with just a single measuring point, LAMS guarantees maximum bending accuracy, guarantees that even the first part is a good part, and is the correct option for Xpert users who place the very highest of demands on the system.

The combination of the Optical Bend Guiding System and the LAMS greatly enhances press brake operations, increases productivity and increases part accuracies.

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, Fax: 847-214-0299, sales.us@bystronic.com, www.bystronicusa.com.