Welding Automation for Small- to Medium-Sized Parts

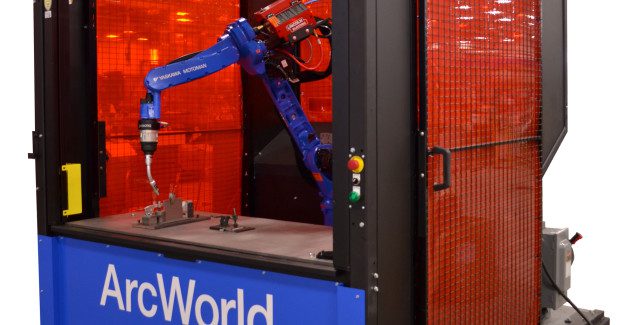

An ArcWorld® C-50 workcell from Yaskawa Motoman includes a six-axis MA1400 Master Arc welding robot, DX100 controller with menu-driven arc welding application software, integrated welding package, integrated tooling or one or two MH-180 headstock(s), operator station, one or two powered roll-up door(s) and a total safety environment.

Posted: January 11, 2014

Featuring one or two stations with fixed tooling or servo headstock positioner(s) in an extremely compact footprint, ArcWorld® C-50 workcells from Yaskawa Motoman (Dayton, OH) provide affordable, wire-to-weld solutions for small- to medium-sized parts at high production volumes.

ArcWorld C-50 solutions provide all the automation needed for arc welding, including a six-axis MA1400 “Master Arc” welding robot, DX100 controller with menu-driven arc welding application software, integrated welding package, integrated tooling or one or two MH-180 headstock(s), operator station, one or two powered roll-up door(s) and a total safety environment.

ArcWorld C-50 models include a single welding station with fixed tooling riser (AWC-50) or a servo-driven MH-180 headstock (AWC-50S). Dowel pins can be used for changeover between multiple parts/fixtures. Dual-station models are available with two fixed tooling risers (AWC-52) or with two MH-180 headstocks (AWC-52S). A single large tabletop (AWC-50) or two smaller tabletops (AWC-52) are available as options.

Models that include one or two headstocks provide the ability to position the part during welding. The MH-180 headstock positioner has a 180 kg (396.8 lb) payload overhung 200 mm (7.87 in) from the faceplate. Due to high capacity, tailstocks are not needed in these compact cells.

The total safety environment complies with both U.S. and Canadian safety standards. Powered roll-up doors improve ergonomics and are interlocked with robot operation to safeguard the operator during part load/unload. In addition to barrier guarding with arc screen curtains, safety features include a single point of operator control, dual-channel light curtains and enhanced E-stop functionality, safety interlocked gates, integrated speed monitoring and manual brake release for the robot.

Shipped pre-assembled on a common base, ArcWorld C-50 workcells are easy to set up. Power supplies and equipment are shipped on a second base. Twist-lock connectors are included on all interconnection cables.

Yaskawa America, Inc., Motoman Robotics Division, 100 Automation Way, Miamisburg, OH 45342, 937-847-3202, sally.fairchild@motoman, www.motoman.com.