When Good Gets Better: Cutting Tools Industry Snapshot

In their search to reduce production cycle times, lower tooling costs and achieve higher precision machining of new materials, shops are demanding new cutting tool solutions that meet higher machining parameters, more process complexity, exotic alloys and a variety of other challenges. Here are some of the newest cutting tools that meet these needs.

Posted: January 24, 2014

TOOLING TARGETS SPECIFIC INDUSTRY NEEDS

MSC Industrial Supply Co. (Melville, NU) expands its Accupro line of high-performance, high-value metalworking products with the launch of new milling, threading and tool holding solutions. There are more than 650 milling items, including new variable index tools with offset flute technology that eliminates chatter; a broader selection of Nacro-coated progressive helix tools for optimized high-speed machining in high-tech materials; new “blue coated” tools for accurately tackling hard materials between 55 and 65 Rockwell; and a wider range of uncoated aluminum tools for increased machining versatility.

The new line of expanded threading solutions offer high-quality tapping products without a change in price point. A new general-purpose Accupro multi-tap solution works well across a broad range of materials and applications. Shops can choose from a wider scope of tool holder and drill chuck sizes and a comprehensive high-quality drill chuck program (see Figures 7-8).

MSC offers same-day shipping on its Accupro products and guarantees complete customer satisfaction. In fact, customers have access to MSC’s money back guarantee for all of their purchases, including the Accupro product line.

MSC Industrial Supply Co., 75 Maxess Road, Melville, NY 11747-3151, www.mscdirect.com.

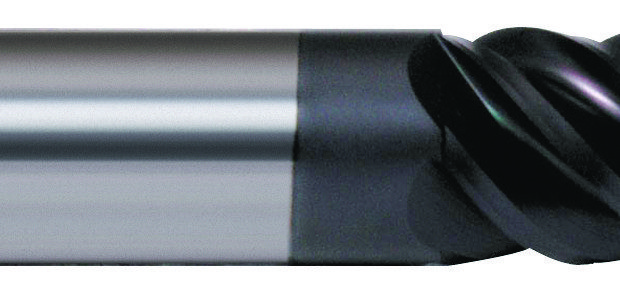

STAINLESS STEEL MACHINING

Walter USA, LLC (Waukesha, WI) introduces their Walter Prototyp Proto•max™ Inox, a solid carbide end mill that typically boosts stainless steel machining performance by as much as 50 percent when compared with conventional, universal solid carbide end mills. This dramatic performance jump is due to the fact that Walter optimized Proto•max™ Inox machines ISO M materials such as stainless steel with features like a four-flute cutter with two internal helical coolant channels for optimized coolant delivery and efficient chip removal – a problem often associated in many stainless steel machining applications (see Figure 9).

Demonstration of Walter Prototyp Milling Protomax Inox milling stainless steel.

These mills ensure a high degree of process stability and increased tool life while simultaneously boosting productivity. The Proto•max™ Inox features a new TAA coating with a TiAlN base and an optimized micro geometry to increase wear resistance and protect against edge build up. It also provides for a smooth workpiece finish. With its unequal 35 deg and 38 deg helix angles this new end mill is able to achieve low vibration operation, boosting tool life and significantly improving surface quality.

These features make the Proto•max™ Inox an ideal choice whenever high machining rates and superior surface finishes in the machining of materials from the ISO M group are priorities in general mechanical engineering, medical and food processing equipment, and aerospace engineering. The mills come in diameter ranges from 6 mm to 20 mm, with or without corner radii. To aid busy users in rapid tool selection, Walter has inscribed the code letter M on the shank of the tool. This stands for the ISO M material group, allowing the users to immediately identify the primary application of the tool.

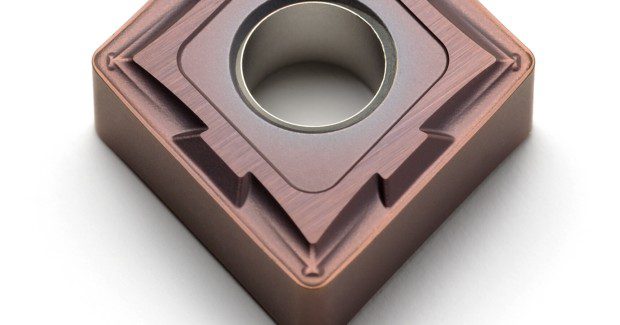

Walter USA also introduces Blaxx™, a groundbreaking new shoulder mill that combines precision, high metal removal rates and process reliability in a single tool, with a visually arresting high-gloss black finish that is both wear and corrosion resistant. These F5041 and F5141 shoulder mills feature highly precise indexable insert pockets that position the inserts accurately and securely. These tools are also fitted with tangential inserts that can not only increase the insert area presented to the workpiece but also enhance tool body stability for a productive and highly robust tool characterized by quiet, low-vibration operation and exceptional process reliability (see Figure 10).

http://youtu.be/JZYYW0AORKE

A demonstration of the Walter Tools Blaxx Tangential Milling Cutter.

These advantages are magnified by Walter’s precision inserts. Manufactured in sizes LNHU0904 and LNHU1306, they have four cutting edges per insert that allow for low horsepower consumption and high metal removal rate. The highly controlled runout and concentricity of the body. Their precise 90 deg perpendicularity to the workpiece ensures a high degree of accuracy. Cutting depths of up to 12 mm are possible with the larger LNHU1306 indexable insert. Since the insert pockets and chip clearances for the tangential inserts demand less material in the tool body, smaller tool diameters can be achieved, with higher density capabilities than with other mill designs.

Blaxx™ performance is further enhanced by the use of Tiger•tec® Silver, Walter’s new high performance coating. Tiger•tec® Silver delivers both superior tool life and increased productivity thanks to its advanced properties. These include increased high-temperature wear resistance with no loss of toughness. This combination of toughness and high wear resistance permits higher cutting speeds while also lengthening tool life.

Walter USA, LLC, N22 W23855 RidgeView Parkway West, Waukesha, WI 53188, 800-945-5554, Fax: 262-347-2501, www.walter-tools.com.