Advanced Indexable Carbide Inserts for Machining Superalloys

Synergy from American National Carbide is a state-of-the-art carbide substrate, enhanced by the latest nano-coating technology that is engineered to perform at the elevated temperatures common when machining superalloys.

Posted: February 19, 2014

Merging the latest technology in engineering, metallurgy, coating, and post-treatment, American National Carbide (Tomball, TX) has created Synergy, a line of advanced indexable carbide inserts for the toughest challenges.

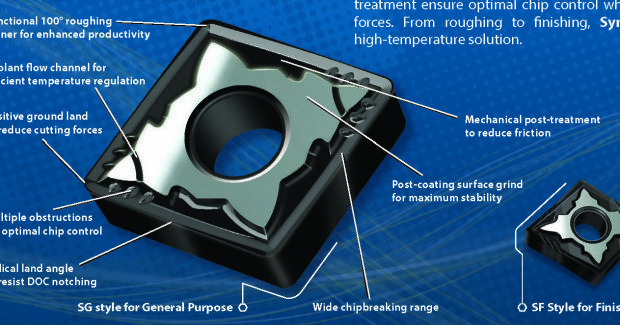

Synergy’s state-of-the-art carbide substrate, enhanced by the latest nano-coating technology, is engineered to perform at the elevated temperatures common when machining superalloys. Synergy’s innovative design and proprietary post-coating treatment ensure optimal chip control while reducing cutting forces. From roughing to nishing, Synergy is your total high-temperature solution.

The Synergy™ line of indexable carbide turning inserts designed for machining challenging high-temperature alloys, such as Inconel. Three new chip-control geometries for roughing, general purpose and finishing applications are offered. The new grade, AN6105, features state-of-the-art, nano-PVD technology, and is engineered to perform at the elevated temperatures common when machining superalloys. A proprietary post-coating treatment and edge preparation ensures optimal chip control while reducing cutting forces. In field tests, Synergy™ performed at 175 sfpm and .085 in DOC with an extended tool life of 20 minutes, beating competitive products by as much as 40 percent.

Features include:

- Functional 100 deg roughing corner for enhanced productivity

- Positive ground land to reduce cutting forces

- Multiple obstructions for optimal chip control

- Helical land angle to resist DOC notching

- Mechanical post-treatment to reduce friction

- Post-coating surface grind for maximum stability

- Wide chipbreaking range

Geometries include the SG style for General Purpose, the SF Style for Finishing, and the SR Style for Roughing applications.

American National Carbide, 915 S Cherry Street, Tomball, TX 77375, 281-351-7165, Fax: 281-255-9333, www.anconline.com.