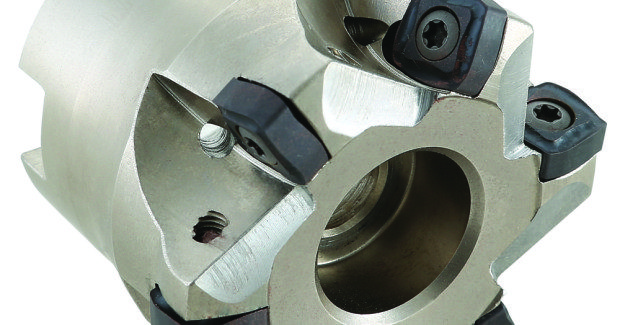

High-Feed Milling Insert

SNKX geometry from Nexus Cutting Tools features eight helical corners with a size and unique design that delivers more cutting edges per insert, thus dramatically increasing productivity.

Posted: February 19, 2014

Nexus Cutting Tools from Techniks Inc. (Indianapolis, IN) introduces its SNKX high-feed insert as the latest addition to its fast-growing solutions for indexable carbide. Optimized for high-feed milling, the new SNKX geometry is the first high-feed square insert available to customers. Featuring eight corners with helical geometry, its size and unique design delivers more cutting edges per insert, thus dramatically increasing productivity.

The SNKX insert is manufactured with proprietary sub-micro grain carbide and advanced PVD coating technology, which is up to five times thicker than most PVD coatings. This allows for machining of multiple materials and ensuring excellent tool life.

The specific advantages of the new Nexus high-feed milling cutters are high material removal rates along with eight economical cutting edges. Applications include face milling, copy milling, plunge milling and roughing operations on pockets and 3D surfaces.

An overview of Nexus Cutting Tools, 5X PVD high-performance inserts, PowerLOC indexable end mills, and Techniks Toolholders and CNC Accessories. These inserts feature a patented PVD coating by Lamina Technologies that is up to 5X thicker for extended insert life, increased feed rates, and improved performance.

With this new geometry, the new insert/cutter combination is just another example of the Nexus promise: Attacking heat and vibration is in our DNA.

The new Nexus cutters are available in standard Weldon shank end mills and standard face mills. Or take your milling to the next level; the new high feed cutters are available in the patented Power-Loc end mills and the patented Shrink-Mill design for zero runout.

All of the Nexus products are backed by a 100 percent performance guarantee. Click here to visit the Nexus Tool website at to see the full line of inserts and other innovative tooling solutions.

Techniks Inc., 9930 East 56th Street, Indianapolis, IN 46236, 877-616-6016, info@nexustool.com, www.techniksusa.com/nexus.