How Advancements in Non-Woven Technology Streamline Metal Fabrication Applications

Innovative design and non-woven materials science have increased productivity while keeping costs down with a new generation of durable, flexible and easy-to-use high-performance surface conditioning products. Shops should utilize new non-woven technology to help them remain competitive in unstable economic times.

Posted: February 19, 2014

According to the Manufacturers Alliance for Productivity and Innovation (MAPI; Arlington, VA), the U.S. industrial outlook for 2014 will show modest growth throughout the year. While this is good news, industrial manufacturers across various industries, from aerospace and transportation, to energy and maintenance repair operations (MRO) and metal fabrication job shops must look for ways to increase productivity while maximizing overall efficiency to keep operating costs down.

The question is: How can industrial manufacturers meet higher demand without increasing overhead?

Metal fabrication processes such as surface preparation and finishing are good places to start. The processes include light stock removal, blending, deburring, preparation, cleaning and finishing. These applications can be very labor intensive and may represent a disproportionate share of the total job cost for metal fabricators.

As the demands for improved finishes increase, and companies like Ford announce the F-150 is moving to aluminum as the primary material, fabricators need abrasives solutions that streamline their operations. Non-woven abrasives can provide an excellent solution.

http://youtu.be/J6S6MCdNn24

Norton Vortex Surface Conditioning TR discs will outperform traditional surface conditioning discs 4 to 1. Utilizing Norton’s proprietary Vortex grain and patented smear-free resin, the Vortex Rapid Blend TR discs will increase productivity and decrease costs in any body shop looking to take advantage of the latest in abrasive technology.

WHAT IS NON-WOVEN?

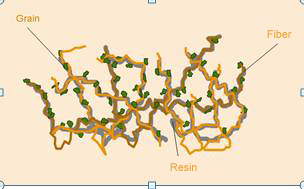

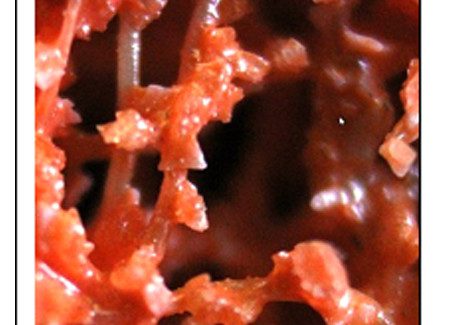

In its simplest form it is an abrasive product where the base is an open nylon filament web to which abrasive grain is bonded. The advantages of non-woven are many. It is resilient, comfortable, waterproof, non-loading, and non-rusting. This allows for the following advantages when used on portable grinding, sanding and finishing operations:

- Provides a controlled cut with minimal stock removal

- Produces a predictably consistent, uniform finish

- Easier to use and can reduce operator training

- Can provide greater safety than other grinding methods

- Can be used on irregular surfaces

NEXT-GENERATION NON-WOVENS

Non-wovens have been around for over 50 years and have been used primarily for cleaning and finishing. Recent advancements in all of the product components have not only improved the core applications, but also extended the performance into other metal fabrication applications.

Non-woven backing – an expansion in the porosity of the fibers from very open to very tight have provided products that work across more applications and materials. Non-wovens now offer strong performance in light metal removal, deburring, blending and finishing and excel on material where loading is an issue.

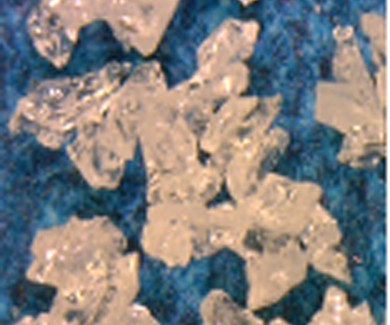

Bond chemistry – previously when the resin overheated, it would often smear the work surface. New bond chemistry (such as CleanBond™, for example) has virtually eliminated this.

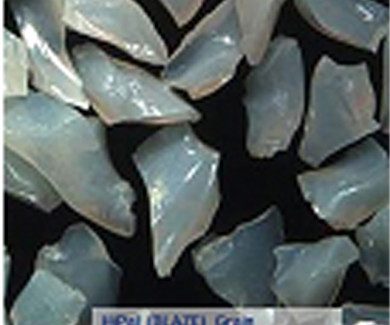

Grain technology – once the domain of fine grit, low cost aluminium oxide and silicon carbide abrasives, the new resins and nylon mesh now allow for the integration of not only coarser grits, but also premium abrasives. Extra coarse (36-40) and coarse (50-80) are now used for stripping and light metal removal.

High performance grains such as ceramic alumina with its ultra-sharp, micro crystal structure and agglomerated grains that allow coarse grits to be built out of finer particles are revolutionizing the cut rate and life of all non-woven products.

PRIMARY ADVANTAGES OF NEXT GENERATION NON-WOVEN

As previous stated, the Next Generation of Non-Woven provides the benefits of faster cut rate, longer life and less rework due to smearing. Also, these products are extremely versatile. In many cases multiple operations can be done using one non-woven disc. The innovative disc material is stiff enough for challenging applications, but also soft enough to prevent gouging that can necessitate rework.

An open mesh structured product does not load on coatings, adhesives or softer metals. When used to deburr, the discs will not snag or shed like cloth or fiber discs. This advanced technology allows for improved cycle times, abrasive life and overall cost per part savings, compared to traditional aluminum oxide grinding products.

NON-WOVEN INDUSTRY OVERVIEW

Aerospace

For aerospace manufacturing, advanced surface conditioning products can be extremely useful for blending and deburring applications involving airframes and investment cast parts. By simplifying the process, aerospace manufacturers are now able to reduce cycle times, enhancing productivity and efficiency.

Transportation

These new technologies are also ideal for automotive, trucking and bus applications, such as frame repairs, weld blending, and surface paint preparations, including scuffing and blending. By providing fast, smear-free performance, transportation industry manufacturers will improve productivity by reducing labor requirements for surface finishing operations.

Energy

In addition, quick and effective surface conditioning can help energy generation manufacturing operations meet tight deadlines and decrease downtime. For example, new non-woven technology can be used in oil and gas operations to deburr pipe threads for rapid and precise pipeline fittings. Wind power operations can refurbish turbines and repair cracks in turbine blades. Better finishes and improved productivity will result in fast and efficient operations – key in energy generation.

Metal Fabrication

Finally, maintenance and repair operations (MRO) and metal fabricators can use these recent innovations in non-woven surface conditioning for various applications, including blending, deburring and weld blending, surface prep prior to painting, rust and paint removal, and surface prep prior to blending.

SUMMARY

Recent advances in non-woven technology have made this a great area to increase productivity while keeping costs down. Innovative design and materials science have combined to yield a new generation of high-performance surface conditioning products that are durable, flexible and easy-to-use. As the economic landscape begins to show signs of improving, manufacturers will be well served to utilize new non-woven technology to help them efficiently meet increased demands while streamlining their operations in order to remain competitive in unstable economic times.