Surface Preparation Wheels and Discs

The surface conditioning line from CGW-Camel Grinding Wheels is specially designed for blending, smoothing and finishing stainless steel, steel, aluminum and nonferrous metals.

Posted: February 20, 2014

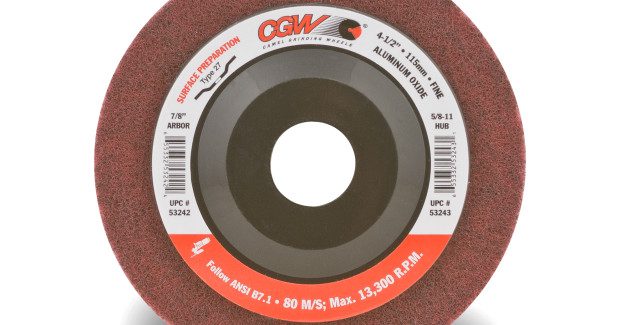

CGW-Camel Grinding Wheels (Niles, IL) expanded its surface conditioning offerings, adding a line of surface preparation aluminum oxide and silicon carbide wheels and discs. The surface conditioning line is specially designed for blending, smoothing and finishing stainless steel, steel, aluminum and nonferrous metals.

Made from nonwoven material impregnated with abrasive grains, CGW’s new surface preparation products remove paint, rust, and welding and cutting discoloration from stainless steel. The maroon-colored aluminum oxide products have a fine grit size, making them ideal for cleaning, blending and finishing stainless steel. The gray-colored silicon carbide products are very fine in grit size, and provide light finishes on metal, wood, composites and satin-finish aluminum.

The new type 27 shape surface preparation wheels are available in aluminum oxide and silicon carbide grains with 4 in, 4.5 in, and 7 in diameters. The type 27 wheels are designed with reduced backing to minimize work piece scratches and allow for full use of the wheel material.

The surface preparation discs have a roll-on attachment and are available in 2 in and 3 in diameters in aluminum oxide and silicon carbide grains.

“The new aluminum oxide and silicon carbide surface preparation wheels and discs allow CGW to offer a fuller line of quality abrasives,” said Joe O’ Mera, president, CGW-Camel Grinding Wheels.

CGW-Camel Grinding Wheels is one of the world’s leading suppliers of grinding wheels since 1956. Its 100,000 sq ft U.S. facility serves as a centralized warehouse with manufacturing capabilities and includes customer service, sales and marketing departments.

CGW-Camel Grinding Wheels, 7525 North Oak Park Ave, Niles IL 60714, 800-447-4248. Fax: 800-447-3731, www.cgwcamel.com.