Take Cast Iron Milling to a New Level

The new insert grade GC3330 from Sandvik Coromant is the first choice for both dry and wet cast iron milling, from roughing to finishing.

Posted: February 19, 2014

Sandvik Coromant (Fair Lawn, NJ) introduces the insert grade GC3330 for cast iron milling, the next machining area covered by the new grades with Inveio™. Having already introduced the game-changing grade GC4325 for steel turning, the innovative cutting tools supplier now introduces GC3330, a wear-resistant first choice grade for cast iron milling.

With predictable performance becoming increasingly important in many machining processes, GC3330 is meeting the needs of today’s manufacturing. The consistent performance of GC3330 creates opportunities for manufacturers to increase machine utilization as well as removing a lot of metal in a short time without compromising tool life. Minimizing machining interruptions also enables secure unmanned machining.

Inveio – the innovation behind GC3330 is equipped with Inveio, the latest innovation in material science. The groundbreaking technology uses uni-directional crystal orientation. While the crystal orientation in conventional inserts’ CVD alumina coating normally is random, GC3330 has controlled crystals lined up towards the top surface. This is the secret behind the endurance, predictability and long tool life of GC3330.

http://youtu.be/kOTOigD82BA

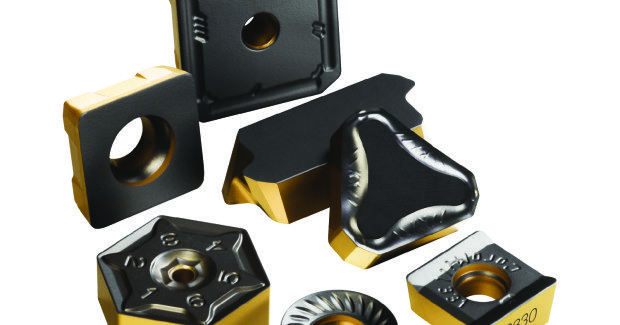

The inside view of steel turning grade GC4325, which uses the same Inveio technology as the GC3330. Note how the separate elements of this unique insert fit together for unbeatable strength, wear resistance and tool duration.

The new insert grade GC3330 is the first choice for both dry and wet cast iron milling, from roughing to finishing. Covering a broad application area, Sandvik Coromant’s new grade can be used in any cast iron milling operation for both grey and nodular cast iron materials. GC3330 is available for a variety of milling cutters for face-, shoulder-, profile-, high feed-, and parting and grooving milling.

steffen.sander@sandvik.com, www.sandvik.coromant.com