Advanced CAM Technology Reduces CNC Machining Time and Extends Tool Life

The latest version of SolidCAM2014 from SolidCAM UK has more than 100 new enhancements across its modules, including 2.5D Milling, HSS, 3D HSM, Simultaneous 5-Axis Milling, iMachining 2D and 3D, Turning and Advanced Mill-Turn for multi-turret and multi-spindle machines, as well as the Solid Probe module.

Posted: March 26, 2014

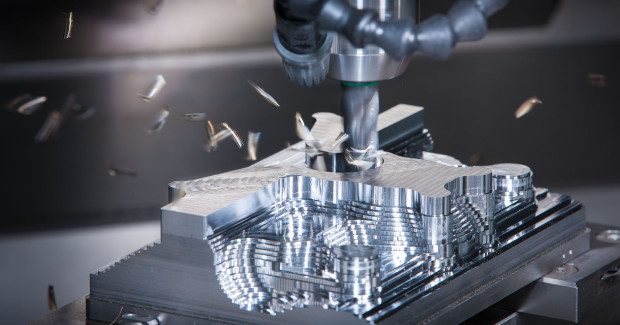

SolidCAM UK Ltd. (South Yorkshire, UK) offers its full suite of SolidCAM CAD/CAM products for milling and turning, including its software for advanced mill-turn applications . Its iMachining technology saves 70 percent in CNC machining time and more, and extends tool life dramatically. The iMachining Technology Wizard provides a reliable partner, automatically determining speeds and feeds and other machining parameters. iMachining provides unprecedented savings and increased efficiency for CNC milling operations, translating into profits and success.

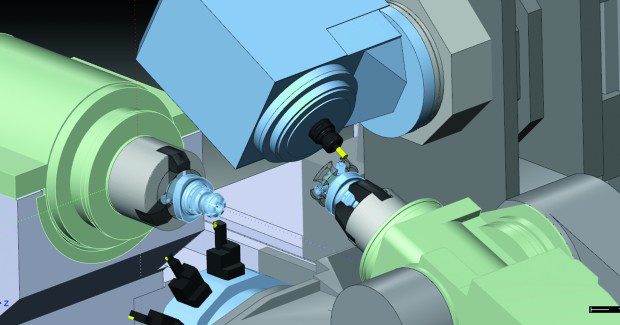

The latest version of SolidCAM2014 has more than 100 new enhancements across its modules, including 2.5D Milling, HSS, 3D HSM, Simultaneous 5-Axis Milling, iMachining 2D and 3D, Turning and Advanced Mill-Turn for multi-turret and multi-spindle machines, as well as the Solid Probe module.

Founded in 1984 by Dr. Emil Somekh, SolidCAM has over 29 years of expertise in CAM development and applications. The integration strategy of the company in the major 3D mainstream CAD systems, SolidWorks and Inventor, has created major growth for the company and established it as a leader in integrated CAM. SolidCAM has had the Certified Gold-product status from SolidWorks since 2003 and provides seamless, single-window integration and full associativity to the SolidWorks design model.

A demonstration of iMachining technology on an open pocket with island. The CAM-Part definition process is automated and the CAM-Part data is saved directly in the SolidWorks part file. A new work material definition is created and then selected from the iMachining Material Database. Based on the Ultimate Tensile Strength (UTS) of the material, the iMachining Technology Wizard automatically calculates the feeds and speeds and synchronizes the step over accordingly. To maintain a consistent Chip Thickness and constant load on the tool, you’ll see that iMachining performs a morphing spiral tool path with a varying step over. You can control the step over with an efficiency slider, which enables you to favor either the maximum side step or a range of side steps calculated by the Wizard. Also generated is the GCode, which shows the changes in feed rate as the tool path varies at each point where there is a change in step over.

InventorCAM has the Autodesk certified product status and provides seamless, single-window integration and full associativity to the Inventor design model. SolidCAM is a consistent growth leader and has been named by CIMdata as the fastest growing CAM vendor worldwide, in five out of the past eight years.

SolidCAM UK Ltd., 19 Fall Bank Industrial Estate, Barnsley, South Yorkshire S75 3LS, United Kingdom, +44 (0) 1226 241744, Fax: 0870 1226338, info@solidcamuk.com, www.solidcamuk.com.