High Power Diode Laser Cladding

Here is a brief overview of high power diode laser cladding that can offer improved process throughput, superior overall clad quality, very low dilution levels, reduced heat input, minimal part distortion and better clad deposition control than most traditional technologies.

Posted: March 5, 2014

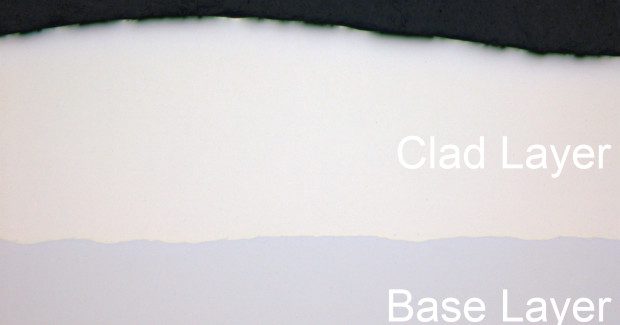

Cladding is a widely used process for improving the surface and near surface properties (e.g. wear, corrosion or heat resistance) of a part or to re-surface a component that has become worn through use. Cladding involves the creation of a new surface layer on top of a base material. This is distinct from surface hardening, which simply entails changing the properties of the substrate itself in a thin surface layer.

There are currently quite a number of different techniques for performing cladding, each with its own specific characteristics in terms of the materials employed, the quality of the clad layer and various practical issues including throughput speed, process compatibility, and cost. This brief overview shares how high power diode laser cladding can offer improved process throughput, superior overall clad quality, very low dilution levels, reduced heat input, minimal part distortion and better clad deposition control than most traditional technologies.

TRADITIONAL CLADDING PROCESSES

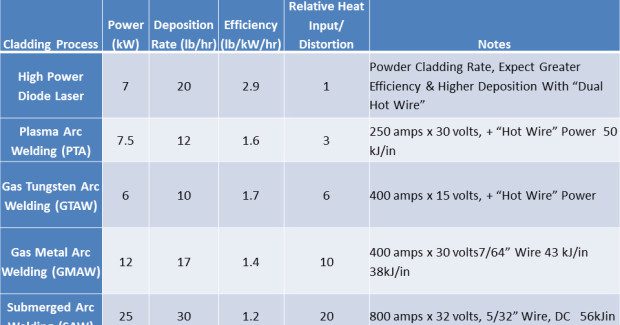

Most traditional cladding technologies can be broadly classified as either arc welding or thermal spraying methods. Each of these approaches has its own advantages and limitations and, as a result, there are certain types of applications for which each is best suited.

http://youtu.be/58i1Rcwsw30

This video demonstration of the highly efficient HighLight 8000D, a high power direct-diode laser system with 8 kW of power at 975 nm. In this video the HighLight 8000D is shown performing large area laser cladding of Stellite 6 (a high quality laser cladding powder from Hoganas) on flat and round low carbon steel materials.

There are a number of different arc welding techniques, such as gas tungsten arc welding (GTAW), plasma transferred arc (PTA), gas metal arc welding (GMAW), submerged arc welding (SAW) and several others. In all these processes, an arc is established to melt the surface of the base material, usually in the presence of a shield gas. The clad material is then introduced in either wire or powder form and is also melted by the arc, thereby forming the clad layer.

The various embodiments of this basic approach differ in the details such as using the filler metal as the electrode, the use of flux, or the ability to use a hot (pre-heated) or cold filler wire. In the most general terms, all arc welding techniques deliver a fully welded, metallurgical bond having high strength, good impact properties and low porosity. Arc welding methods also offer high deposition rates (which translates into high throughput) and relatively low capital cost for the equipment.

The major negatives of arc welding cladding are high heat input into the part and, depending upon the particulars, relatively high dilution of the clad material (that is, unwanted migration of the base material into the clad layer). Heat input into the part can cause mechanical distortion often creates the need for further post-processing after cladding. In addition, it is not always possible to realize in practice the high deposition rates of which arc welding processes are theoretically capable. This is because dilution, heat input, distortion, hardness and other metallurgical properties are sometimes negatively affected when the arc energy is increased beyond an optimum level that is generally at the lower end of the deposition rate range.

In thermal spraying, the clad material, most typically in powder form, is melted by a flame or electricity and then sprayed on to the work-piece. In most cases, this is a low-heat process, where the substrate remains typically < 200 deg C. The four most common embodiments of this approach are flame spraying, arc spraying (where wire is used as a consumable), plasma spraying and high-velocity oxyfuel (HVOF).

The primary advantage of all thermal spraying techniques is the low heat input into the part which means there is no heat-affected zone and minimal dilution. It also enables the process to be utilized with a wide variety of substrate materials including metals, carbides, ceramics and even plastics. Thermal spraying also supports a very broad process window in terms of the range of coating thicknesses that can be achieved and the deposition rates supported, although these coating tend to be thinner than arc welded coatings.

One of the significant drawbacks of thermal spray processes is that the bond between the clad layer and the substrate material is mechanical, not metallurgical, in nature. This can lead to problems with adhesion and poor wear resistance, especially with pinpoint loading. Also, thermal spray claddings often exhibit some level of porosity and bonding defects. The presence of such defects in the coating is of concern because these can provide a path for a corrosive solution to reach the base materials. Reduced corrosion resistance has been reported and appears to be related to preferential attack along the inter-particle boundaries.

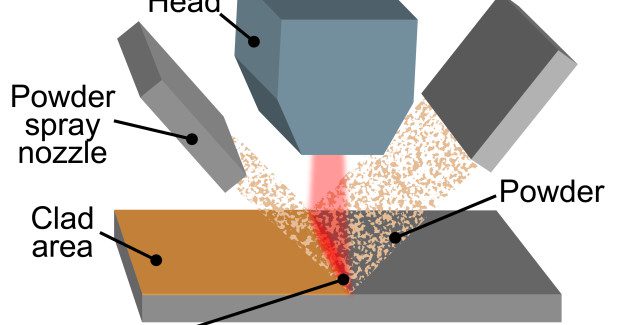

LASER CLADDING BASICS

Laser-based cladding techniques provide several quality and process related advantages over both arc welding and thermal spray methods. However in practice, traditional laser types have not always delivered on this promise and have also displayed significant drawbacks in terms of output characteristics, operating costs and ease of implementation. In response to the need for a more optimal source for applications such as cladding, welding and heat treating, laser manufacturers have developed the high power direct diode laser.

A high power direct diode laser is a compact assembly consisting of a very large number of lower power (about 100 W each) semiconductor laser emitters, whose output is combined into a single beam. Typically, this beam takes the form of a long, thin rectangle, usually around 3 mm wide, and anywhere from 6 mm to 36 mm long.