Milling, Drilling, Tapping and Boring Brake, Engine and Transmission Parts

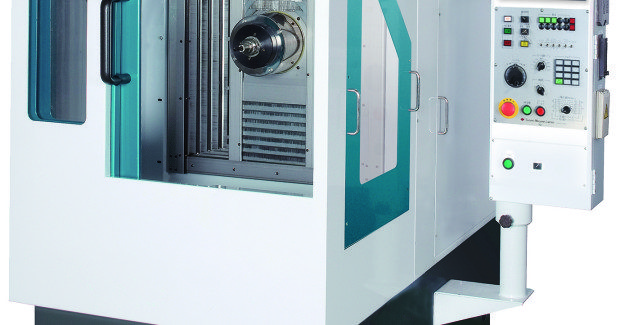

The compact H15 and H15B horizontal machining centers from Sugino feature BT30 high-pressure, coolant-through spindles with maximum speeds up to 15,000 rpm and 20,000 rpm, respectively.

Posted: March 21, 2014

Sugino Corporation (Itasca, IL) introduces the Self-Center™ H15 and H15B Horizontal Machining Centers that are designed for high-precision milling, drilling, tapping and boring of small- to medium-size parts in aluminum, cast iron and carbon steel such as brake, engine and transmission components. The H15 and H15B feature BT30 high-pressure, coolant-through spindles with maximum speeds up to 15,000 rpm and 20,000 rpm, respectively.

Specifically designed for saving space and energy, the H15 sits within a compact 4.5 ft x 9 ft (1,375 mm x 2,750 mm) footprint, while the H15B is even more compact with a 3.5 ft x 9 ft (1,020 mm x 2,690 mm) footprint, using up to 25 percent less space and energy.

Additionally, these horizontal machining centers provide a work area of 11.81 in x 13.78 in x 13.78 in (300 mm x 350 mm x 350 mm), accommodating a weight up to 770 lb (350 kg) for the H15, and a work area of 7.87 in x 7.87 in x 7.87 in (200 mm x 200 mm x 200 mm), accommodating a weight up to 1,100 lb (500 kg) for the H15B.

Sugino Corporation, 1380 Hamilton Parkway, Itasca, IL 60143, 630-626-0518, Fax: 630-250-8665, www.suginocorp.com.