Keeping Pace With Production: Automating Your Solid-State Laser

When a laser system is waiting for material handling, it is not making money. Automated systems must be able to cope with the common differences between laser types. The process of selecting the best choice becomes increasingly involved when the system uses solid state laser cutting machines. Here are some important points to consider.

Posted: March 4, 2014

Fabricators commonly ask, “Is our application better suited to 2D solid state laser technology or CO2 laser processing?” The answer is complex and influenced by many dynamic variables. However, one variable often overlooked is how the decision affects the material handling involved: Automated systems must be able to cope with the common differences between laser types.

Solid state lasers, increasingly the laser option of choice, generally have higher cut speeds. This is especially true when nitrogen is used to cut thin sheet metal. Faster processing of parts leads to an increase in the volume of material that can be moved through a system. Another important difference with solid state technology is that the cut kerfs are much smaller, making automated sorting a challenge. If material handling cannot keep pace with production, the advantages of solid state lasers can be lost.

The merits of solid state lasers mainly revolve around the speed of processing thin sheet metal with nitrogen, and this must be addressed when looking at the automation involved. As processing speeds increase and average nest times drop, it becomes increasingly important for material handling to keep pace. A laser machine is a significant investment and owners do not want automation, a relatively inexpensive component, to keep the laser from running at its maximum rate of production.

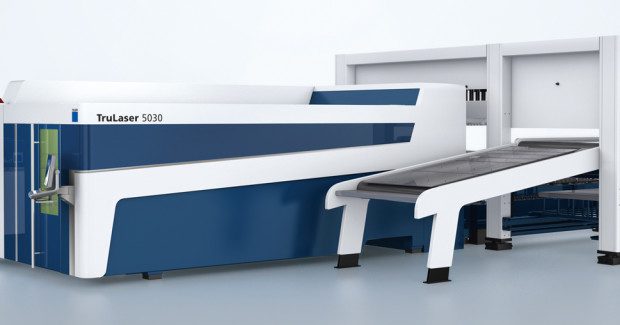

The LiftMaster Compact maximizes productive time for the TruLaser 3030/3040 and TruLaser 5030/5040 laser cutting machines by providing uninterrupted material flow. This combination loading and unloading device loads raw material with suction cups and removes finished sheets with rakes. The fast (65 second) material exchange time means no time is wasted waiting for the next sheet, and automatic operation enables long periods of unmanned operation. Increased storage is possible with the addition of a TruStore material storage system.

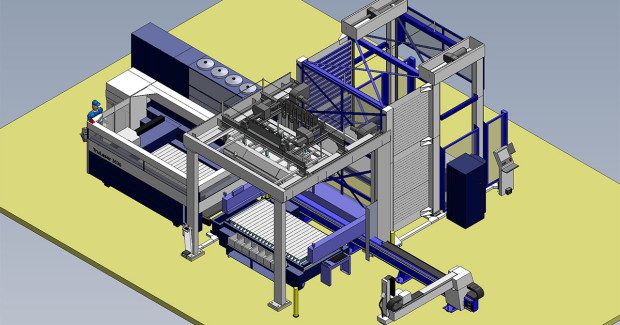

When a laser system is waiting for material handling it is not processing or, more specifically, it is not making money. The cycle time to load and unload a laser machine needs to be reduced to maximize the beam on time. Luckily, automation technology is keeping pace with smart designs that allow units to load and unload a laser machine simultaneously. This can reduce the automation’s cycle time to 90 seconds or less. Other breakthroughs include allowing the automation to serve as an integrated part of material storage towers. Many times the load/unload unit can also serve as the pallet picker.

While all of this aids in saving time at a single machine, the needs of multiple lasers must also be met. It is important to visualize the entire system and production plan as a whole in order to decide between a dedicated load/unload for each machine or for a linear system that serves more than one machine. One unit serving multiple lasers may not be able to keep up as well as it has in the past.

Increased processing speeds and faster automation lead to an increase in the amount of material moving though a production line. To deal with the increase, customers must be able to store more raw materials and finished parts in the same amount of space as before. This becomes increasingly important for customers with lights out operations. Storage towers with very compact spacing between pallets have been developed to store more material vertically, use less floor space, and maximize the ROI of material handling.

For those shops who do not need storage towers, the best option is a load/unload unit with increased stack height. Automation that has a larger Z-direction of travel allow the fabricator to stack more material under the load side and more parts on the unload side of the machine.

Fabricators have also expressed increased interest in automation for sorting laser cut parts. This can be a greater challenge when the parts are processed on a solid state laser cutting machine. Not only does part sorting have to keep pace with the increased speed of the laser, it must also deal with the reduced kerf of the parts, making them harder to remove accurately with standard techniques. As a result, small adjustments to part sorting must be made. Large parts can be removed by picking the parts out of the skeleton or, alternatively, the skeleton is removed from the parts. Smaller parts can be removed and sorted in as little as 15 seconds per part by suction cups. The newest designs will also shake the part from the nest.

If parts are too small to be accurately sorted individually, they can always be tabbed into a small nest and removed as a unit. This is also a useful tactic to employ when kitting. With the developments made in part sorting, there are still times when a human can do the job faster and more accurately than is possible with machines. In that case, material handlers can be combined with a conveyor system that moves cut sheets to a sorting station. Users of this type of system have increased sorting productivity by 30 percent by adjusting the ergonomics of the sorting station.

Automation options are varied, numerous and often confusing for a fabricator to navigate alone. The process of selecting the best choice becomes increasingly involved when the system involves solid state laser cutting machines. Involving professionals with a deep understanding of automated systems early in the process not only aids in choosing the right material handling and storage solutions for the current shop floor, but also in planning for business growth in the future.