Advanced Software Drives Laser Cutting of Electrical Laminations

European Electrical Laminations uses Lantek Expert CAD/CAM software on its Trumpf laser cutting machines to produce electrical laminations for stators and rotors, armatures, stator segments, and pole laminations for motors and generators used in wind turbines, high speed rail and power generation.

Posted: March 14, 2014

CAD/CAM software from Lantek Systems Ltd. (Malvern, UK) has helped European Electrical Laminations Ltd. (Netherton, England) focus on the bespoke end of the laminations market.

Based in the West Midlands of the UK, the manufacturer, which can trace its roots back 40 years, produces electrical laminations for stators and rotors, armatures, stator segments, and pole laminations for motors and generators. These are used in a diverse range of applications including wind turbines, high speed rail and power generation.

Technical manager Geoff Brookes says, “We cut silicone steel between 0.5 mm and 0.65 mm thick, which is then built up into core lengths. The profiles are to customer design, which we import into our AutoCAD system.”

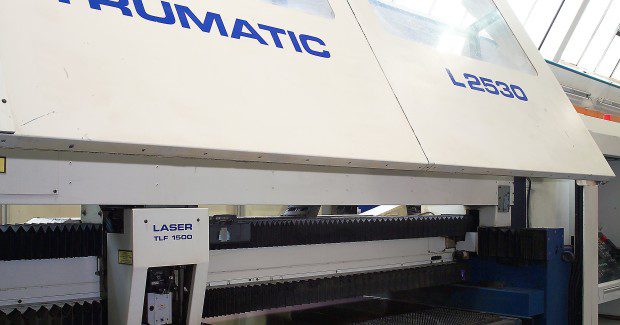

Traditionally, laminations are cut with hard tooling, which can cost many thousands of pounds to produce, making it a very expensive and time consuming option for special applications and small quantities. Brookes states, “We purchased three pre-owned Trumpf L2530 laser cutting machines three years ago with the aim of offering a better solution to our customers. Lantek Expert was recommended to us, and after a three-day training course we were up and running.”

Laminations are circles with features or circle segments, depending on the design supplied to European Electrical Laminations, generally between 50 mm and 1250 mm in diameter, the largest size that will fit on the Trumpf.

Here is a brief introduction to Lantek Expert Cut.

Brookes explains, “The laser is an inexpensive way of producing blanks. We transfer the CAD data into Lantek Expert using DXF or DWG files and automatically nest the required blanks into one of our stock sheet sizes. We mix products in the sheet as the software puts smaller parts in holes or areas, which would otherwise be scrap. If we want to, the software gives us the flexibility to further manipulate the nest to get even better material utilization. For the slots in the laminations, we use other special machinery with hard tooling to complete the job.”

All three of the Trumpf machines are fitted with an automated pallet changing system, which allows parts to be unloaded by the operator while the next sheet is being cut. Geoff Brookes says, “We can make quantities of laminations from just 200 to around 6,000 with this process, which gives us a big competitive advantage as hard tooling to do the same job could cost around $33,272. We find that the vast majority of our customers are very happy with the laser cut finish.”

Bespoke laminations make up approximately 40 percent of European Electrical Laminations’ business, so these lasers and CAD/CAM software are an essential part of the company’s business model.

It automatically generates collision free laser paths which avoid crossing previously cut components. The support is very good too, with questions dealt with immediately through online remote operation of our software. We are very satisfied with it.”

European Electrical Laminations Ltd., Newtown Works, Cradley Road, Netherton DY2 9SW, England, +44 (0) 1384 413 770, Fax: +44 (0) 1384 413 260, sales@eell.co.uk, www.eell.co.uk.

Lantek Systems Ltd., Malvern Hills Science Park, Geraldine Road, Malvern, Worcestershire WR14 3SZ, United Kingdom, 01684 585384, Fax: 01684 585201, rob.powell@lantek-systems.co.uk, www.lantek-systems.co.uk.