Other Advances in Laser Welding and Cutting

Here are some of the latest advances that combine laser flexibility with its increasing power, improved cutting speeds and better edge quality that lower operating costs and help shops reduce their need for secondary operations.

Posted: March 5, 2014

Beyond high power diode laser cladding technology, the flexibility of lasers has led to widespread advances in robotic applications, along with the introduction of laser welding and cutting of new materials in many different industries. Here are some of the latest advances that combine laser flexibiity with its increasing power, improved cutting speeds and better edge quality that lower operating costs and help shops reduce their need for secondary operations.

LASER WELDING AND LASER HYBRID WELDING

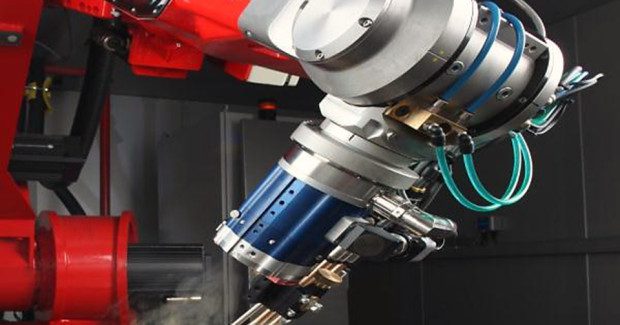

Reis Robotics (Elgin, IL) presents their newly developed laser robot RV60-26-FT for laser welding and laser hybrid welding. This laser robot is offers improved load capacity for the new process technology, a higher transmittable laser power, a bigger reach, and extended interfaces and adjusting features. It is possible to transfer fiber, disk, or diode lasers up to 16 kW laser capacity due to the field proven integrated laser beam guidance and the welding optics MWO54. It is possible to set the focal point diameter via the robot control; hence, both “deep welding” and “heat conduction welding” are possible.

The integrated cable channel in the upper arm of the robot structure ensures the 3D mobility of the system. The solution for laser hybrid welding is unequaled. Depending on the design, the weld robot including sensors can be guided via the 6th robot axis without additional adjusting axes. This means the economical welding of crane jibs, side walls for railway wagons, and bumpers for vehicles is possible.

Reis Robotics, 1320 Holmes Road, Elgin, IL, 60123, 847-741-9500, cclark@reisrobotics.com, www.reisroboticsusa.com.

FIBER LASERS ADVANCE SHOP CAPABILITIES IN CONTRACT LASER CUTTING

Ohio Laser LLC (Plain City, OH) started using CO2 laser-cutting machines in 1997 when laser technology was considered a revolutionary change in cutting capability. Today new fiber laser cutting technology is the next generation and replacement for traditional CO2 laser machinery on thinner gauge materials. While the fiber laser has not quite equaled the degree of change (from what existed before the laser), it is still a significant improvement.

To begin with, the fiber laser cuts at much faster speeds than conventional CO2 laser machines, increasing plant throughput while lowering operational costs. This is possible because the fiber laser resonator generates a superior beam delivered through a fiber cable that maintains the beam quality to the cutting head. There are no moving parts in laser or beam delivery. Conventional lasers deliver the beam by way of mirrors and bellows, creating a very long beam path with plenty of moving parts, prone to contamination and leading to decreased efficiency.

Additionally, fiber lasers offer users huge wall-plug efficiency. Conventional CO2 laser machines are about 6 percent to 10 percent efficient (at best) at turning electrical energy into light. Instead, fiber lasers return electrical energy into light at 28 percent wall-plug efficiency, which means that fiber lasers are about three to four times more efficient, presenting a huge difference in cost savings for the fabricator, and inevitably for the customer.

Ohio Laser has been cutting parts with fiber laser machines for over two years after TRUMPF Inc. (Farmington, CT) selected them as one of its first beta test sites for the TruLaser 1030. Although conventional CO2 laser-cutting machines are still a better fit for cutting materials with over ½ in thicknesses, especially stainless and carbon steels, the fiber laser cuts thinner gauge steels and other materials faster and more efficiently.

Fiber laser technology has also enabled the company to penetrate additional markets and been a door opener for opportunities with respect to highly reflective metals. With the fiber laser, the shop can now cut copper, brass and bronze with speed and efficiency as well. These materials were considered difficult to cut before.

Fiber laser technology also offers their customers a variety of other benefits, including full production freedom and flexibility. They can count on high quality precision cutting design on short notice, the flexibility to build prototypes quickly and easily, the advantage of being able to easily test changes on-the-fly and cost savings from lower unit part costs.

Ohio Laser LLC, 8260 Estates Parkway, Plain City, OH 43064, 614-873-7030, Fax: 614-873-7040, sales@ohiolaser.com, www.ohiolaser.com.

LASER DEPOSITION WELDING

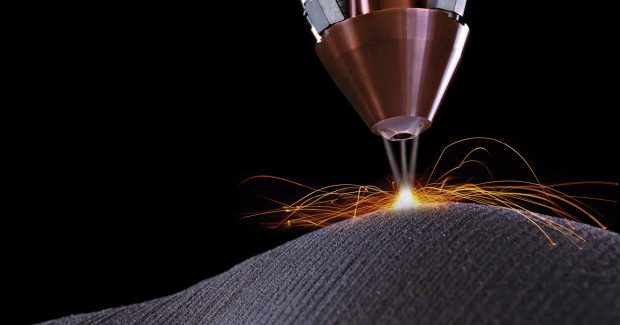

Deposition laser welding, or Laser Metal Deposition (LMD), is a generative laser-based welding process that builds metal up in layers on existing tools and components that offers great savings potential for making small modifications or design changes to the end product and for correcting processing faults.

Volume build-up can be used to compensate for failures, achieve specified nominal dimensions and make old components useable again with little effort while retaining the material characteristics and the load capacity of the original component. The durability of the repaired form is comparable to that of a newly made mold insert.

This demonstration of a TruLaser Cell 3008 mit DepositionLine shows how the TruLaser cell 3008 can be used for both 2D and 3D processing.

LMD is the answer to wear or modification requirements. The DepositionLine from TRUMPF Inc. (Farmington, CT) can produce metallic material depositions on existing components as though it were cast, without any loss of quality, well-sealed and free of pores and cracks.

When using the DepositionLine for laser deposition welding, the laser generates a molten bath on the prepared surface before powdered material is guided through the nozzle to the surface. Once this new layer of material has cooled, the next layer is added. The finished piece is free of pores or cracks, and as strong as if it were cast.

The DepositionLine consists of three major functional units: the powder conveyor, the powder conveyor line, and the processing optic with powder nozzle. The powder conveyor is a mobile unit directly next to the laser processing machine. The powder/gas mixture from the individual containers is combined in the powder conveyor to form a powder mass stream, and fed to the powder nozzle as a precisely regulated flow.

TRUMPF Inc., 111 Hyde Road, Farmington Industrial Park, Farmington, CT 06032, 860-255-6104, Fax: 860-255-6424, susan.grohs@us.trumpf.com, www.us.trumpf.com.

IMPROVE ROBOTIC LASER CUTTING PATH ACCURACY AND PROGRAMMING FLEXIBILITY

As laser cutting continues to emerge, ABB Robotics, Inc. (Auburn Hills, MI) has introduced two new, seamlessly integrated laser cutting software products that make laser cutting with ABB robots more accurate, highly flexible, and easier to program and operate.

The new RobotStudio Cutting PowerPac is an add-on to RobotStudio, the 3D offline simulation programming tool that allows operators to generate and modify program cutting paths based on part geometry and CAD models. The second new software, RobotWare Cutting, is a robot controller add-on that features sophisticated tools for the integration of peripheral equipment, robot tuning and calibration, and the programming of complex paths and shapes.

ABB’s innovative robot software, rigid arm design, and Iterative Learning Control provide the most accurate path creation of any robot in the industry. It also has the fastest acceleration and deceleration, which translates to shorter cycle times and increased production. State-of-the-art precision features include: Iterative Learning Control (ILC), Automatic Friction Compensation, Dynamic Motion Model, TrueMove™ and QuickMove™ software. Integration with RobotStudio™ off-line programming software also means fast, accurate programming for laser processing applications.

Laser cutting is a non-contact process, so the laser equipment does not wear and no trim presses or trim dies are required. The process is highly precise, and trim lines and feature sizes and locations can be easily adjusted to handle a wide variety of parts. Robotic laser cutting offers several advantages over traditional 5-axis laser cutting machines, including up to a 35 percent lower initial investment, reduced operational costs, and a smaller footprint that allows easier integration into existing manufacturing systems.

“The Cutting PowerPac takes robotic laser cutting to the next level, greatly simplifying the programming of parts all shapes, even those requiring the most complex paths,” says Erwin DiMalanta, a senior manager at ABB Robotics. “And users can create and test advanced cutting programs offline, in an office environment, maximizing production uptime and resource efficiency.”

RobotWare Cutting is compatible with most common laser cutting equipment brands, and its intuitive graphical user interface makes it easy to use. The interface provides the flexibility to switch automatically and quickly between different product series allowing even the shortest cutting runs to be efficient and of the highest quality.

Users of ABB Robotics’ laser cutting systems also have to all the benefits of ABB’s Remote Service, a system which provides remote access to the system for production monitoring, fast diagnostics and predictive maintenance.

ABB Robotics, Inc., 1250 Brown Road, Auburn Hills, MI 48326, 248-391-9000, mark.x.oxlade@us.abb.com, www.abb.com/us.

LASER AND ELECTRON BEAM WELDING

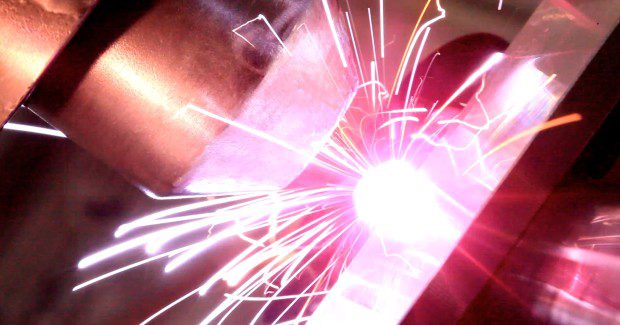

Joining Technologies, Inc. (East Granby, CT), an innovator in laser cladding, electron beam and laser welding applications, announces comprehensive joining capabilities in both laser beam welding and electron beam welding. These expanded capabilities are being used to take on more welding projects in the medical device and aerospace industries by streamlining the manufacturing process for products that use both Laser and EB for different steps, including sensors, medical devices and products that require a sealed vacuum.

Joining Technologies uses laser cladding of metal powder alloys to enhance, repair or free-form material for applications in aerospace, power-generation, valve and O.E.M.-supplied components. The L.A.P.® process can offer positional accuracy while maintaining material quality and metallurgical bonding. Parametric accuracy of the system allows for clad layers as thin as four-thousandths of an inch, with maximum clad thicknesses ranging over 3 in.

Qualified in-house engineering resources take full advantage of each technology’s particular advantages when fusing together complex geometries and meeting demands for superior metallurgy. Having access to both technologies can be especially useful for jobs that require a vacuum within the finished part. Generally a laser will be used wherever possible to keep cycle times and costs down while EB is employed to achieve the deeper penetration welds or to create a vacuum.

Joining Technologies, Inc., 17 Connecticut South Drive, East Granby, CT 06026, 860-653-0111, Fax: 860-413-9029, sales@joiningtech.com, www.joiningtech.com.