Practical Success: Measurable Energy Savings in Die Casting Automation

The integrated control system inside this standard casting cell with trim press from Reis Robotics saves the Pierburg foundry up to 30 percent on energy consumption.

Posted: March 14, 2014

The increase of energy efficiency is possible in very many areas of automation technology, beginning with the robot and its power consumption through to the control systems in the robot that may contribute as energy managers, controlling the various systems involved in the process so they will not consume more energy than necessary.

A precondition necessary to accomplish this is that automation specialists must possess high process know-how. A turnkey supplier of total systems must be able to offer solutions optimizing the complete process and integrating all connected systems – not only robots – into a central control arrangement. Experience shows that it is not the robots that are the biggest energy consumers, but the entire peripheral equipment.

MELTING, CASTING AND SAVING ENERGY

Potential savings in a foundry operation are not evident at first, where metal is molten and then injected into a die with high pressure. How can you save anything here?

Reis Robotics USA, Inc. (Elgin, IL) measured and examined a foundry process for energy optimization and the results were very surprising: in foundries that are not yet optimized, more than 40 percent of the energy consumption takes place in standby operations outside the production process itself. The robot is one of the lowest consumers in this.

In many cases, these systems are not switched off in standby operation between the production cycles so they continue to consume energy. Analyzing a conventional 800 ton standard casting cell, the trim press alone in standby operation consumes about five times as much energy as all other peripheral units. Annual energy costs in the five-figure range may soon arise without having anything produced. Consider that the effective production time makes merely 60 percent of the total duty cycle and the saving potential becomes evident.

Dr. Michael Wenzel, the general manager of Reis Group Holding, states, “We were surprised at how much energy is unnecessarily consumed in some systems. The final question is how to optimize the energy consumption for an entire process or system. This step is only efficient and economical if optimization itself does not cause new high costs.”

Pierburg (Nettetal, Germany) used numerous die casting processes for many years. In view of rising energy costs and an anticipated move, a plan arose to optimize its automated processes regarding cycle time and the use of energy. All operations were put to the test. The idea was developed to split punching and trimming into two steps so that after the rough cut the fine cut will run free from faults. Air cooling of the castings also improved in the project since, during further processing, no blast agent will stick to angular, still moist contours.

The goal was development of a flexible standard cell for a multitude of products, saving energy wherever it is not needed. In the project, a sample cell was created that distinguishes itself by considerable improvement in energy efficiency. Detailed energy consumption analyses were made before actually using the cell. The resulting findings were utilized in the project with regard to energy savings.

The prerequisite for optimal energy saving was a superimposed control level being able to map the most diversified products and vary the cycles for all connected system components and peripheral units accordingly. The idea was to develop a so-called head control with freely programmable production sequences together.

Depending on the product being manufactured, paused system parts can enter into a sleep mode operation to switch off those drives that are not needed at the moment to save a lot of energy. The suction hood over the casting machine, the press drives, the robots, and the cooling fans are switched off at the push of a button on the central operating unit or automatically by the central controller.

Additionally, there are weekend and pause buttons to centrally switch off all media, drives, and lights. Due to this innovation in automation technology, Pierburg now realizes an overall energy savings of up to 30 percent.

First, energy is used for the melting process and casting itself, then additional energy is required for cooling of the parts before further processing. This means considerable energy savings can be leveraged by an intelligent control. Quench tanks more often use thermostatic cooling water controls and automatic switch-off of the cooling water circulation in order to not waste this energy. And a certain casting residual heat is absolutely desirable for fast drying of the parts.

For cooling of castings with air, the use of speed-controlled fans and an automatic switch-off at all deposit places in the cooling shelf where there is no casting was recommended. In the cooling shelf from Pierburg, there is space for ten castings. Sensors in the shelf recognize when a part is inserted and only switch on the relevant fan for a defined time. Temperature sensors are also possible and have already been considered in the control.

At Pierburg, the robot picks the parts from the shelf after cooling and feeds them to the next work step, followed by insertion into the two Reis trim presses. Activated by the head control, their drives stand still until a work step is waiting again. A conveyor system transports the scraps into a bucket; from there, the scraps are fed to melting-down. This system component is switched off as soon as no transport is necessary.

Robots in an automated die casting cell contribute comparatively little for energy consumption, yet some further optimization saved more energy. Generally, the ROBOTstarV control is in a position to switch off the drives of the robot if these are not used. As soon as the control gets the signal for the next work step from the connected peripheral equipment, same will be activated again immediately – comparable to a screen saver.

Energy efficient drive motors and innovative servo controllers allow further energy savings. Modified drive motors reduce heating and at the same time lower the expenditure for control cabinet cooling. Modified servo-converters of the drive components use the brake energy of a robot axis by buffering it in an intermediate circuit for subsequent acceleration of another axis.

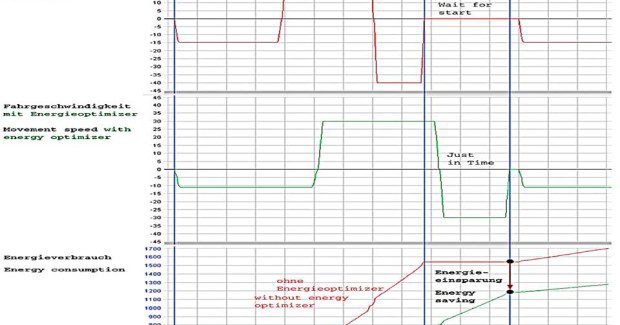

The ROBOTstar intelligent control allows to accelerate drives only as fast as required – not as possible – in order to meet the required process speeds. These optimizations in total save a considerable share of energy as the accompanying diagram explains.

Trim presses from Reis have a so-called load-sensing. This function allows even faster production if the full performance is not required and saves energy. Pumps no longer feed against over-pressure valves with full capacity and thus generate less heat loss.

Reis also included the motors of these pumps in its consideration. New, highly energy efficient motors in the Reis presses save the additional procurement costs. The break-even for a 15 kW electric motor was already reached with a service life of approximately 1,000 hours. A 22 kW motor reaches this effect after only 600 hours of operation.

The central control of Reis Robotics can optimize the provision of compressed air because it is very energy intensive and, thus, an expensive medium. Each savings has an immediate measurable effect on the operating costs.

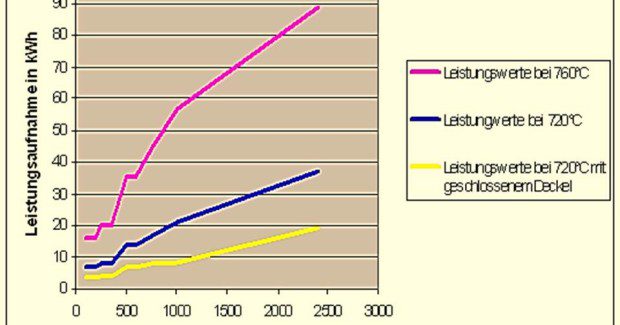

According to experience from Reis Robotics, for some crucible furnaces the temperature may be slightly reduced without impairing the safety or quality of the casting process. An example explains that more than 50 percent of energy can be saved in aluminum casting if the temperature is lowered by only 40 deg C. If the crucible is also furnished with a flap cover during the time when nothing is taken out, additional cash can be saved.

Pierburg is convinced of the savings and of the production flexibility Reis Robotics has enabled with the new “head-controlled” casting cell. The responsible parties will use this time before the planned move for additional tests to multiply the flexible casting cell configuration at their new site. Two to three additional cells will be installed at the old site.

The foundry management at Pierburg sees an enormous advantage of the controls in the fact that troubleshooting can be made in the program via remote access from Reis, from their Frankfurt-area headquarters, without any travel charges. Thus, the systems for the new site will be considerably more economical.

Reis Robotics USA, Inc., 1320 Holmes Road, Elgin, IL 60123, 847-741-9500, cclark@reisrobotics.com, www.reisrobotics.com.