Reducing Heat Input the Smart Way for Joining Thin Sheets

microMIG from SKS Welding Systems North America uses a pulsed wire feeding technology. Compared to other methods with pulsed wire feeding, microMIG is characterized by a significant difference: instead of using higher frequencies of the wire pulse, microMIG achieves higher deposition rates at lower frequencies.

Posted: March 20, 2014

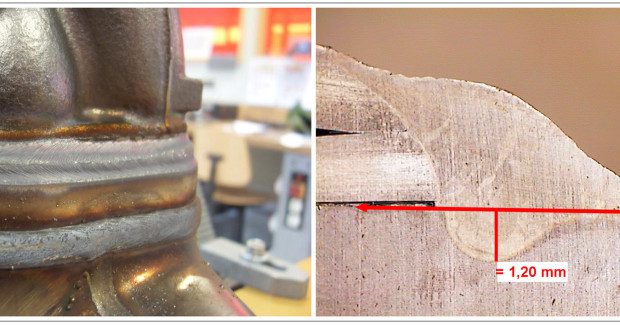

Every tried and tested welding and soldering method offers advantages in its specific field of application. For microMIG from SKS Welding Systems North America (Troy, MI), this is especially the case with sheet thicknesses between 0.5 mm and 1.5 mm: well controllable reduced heat input, good gap bridging, minimum distortion and virtually spatter-free results.

And there is even another advantage over other so-called “cold” measures, i.e. heat-reduced arc welding processes, since these features are all achieved using low-cost standard equipment of SKS. The user simply changes the torch, even the standard wear parts such as the contact tip and gas nozzle remain identical.

When welding thin sheets, the optimal heat input is just as low as it is required to achieve a metallurgically intimate connection or the required degree of penetration. This applies in the same way for brazed joints or for the welding of thin sheets with thicker materials such as castings. With microMIG, SKS has developed a process that leads to the desired result without using expensive special equipment.

Eberspächer Exhaust Technology, a leading manufacturer of exhaust systems, is successfully using this technology. “The microMIG welding solution convinces us when joining our lightweight exhaust systems in daily industrial practice. With the formerly used MAG process, the distortion was up by thirty-five to fifty percent. As we only change the torch system, investment is kept in very manageable limits,” said Roman Lauer, the head of joining technology for Eberspächer, in summarizing their practical experience.

The technology is based on a patent of the developer of digital welding technology, Volker Leipold, dating back to 1997. The Frontpull 7 torch for robots with external cable dress contains this patented, electronically controlled motor. The other components of the welding system are the same as those of a weld package for electric arc welding. This also means that users can continue to use either their existing equipment by changing the torch or, if they additionally desire a microMIG system, opt for a low-cost standard system that allows retooling, thus using it for other welding processes that are better suited for joints involving thicker materials.

microMIG uses a pulsed wire feeding technology. Compared to other methods with pulsed wire feeding, microMIG is characterized by a significant difference: instead of using higher frequencies of the wire pulse, microMIG achieves higher deposition rates at lower frequencies. The higher the desired deposition rate, the longer are the pulse sequences. The lower pulsed motion of the wire results in a lower load of the wearing parts in the torch system including the drives.

Another feature with positive effects is provided by the choice of parameters. Instead of having the option to only control the pulse rate, users of microMIG can additionally adjust the pulse delay, the base current, the wire feeding speed, and the wire retraction time. The resulting benefits include a longer service life, better quality of the weld seams, better looking weld seams, low component distortion and less rework effort.

SKS North America, 2040 Austin Drive, Suite B, Troy, MI 48083, 248-519-5079, Fax: 248-519-5080, jcolosimo@sks-welding.com, www.sks-welding.com.